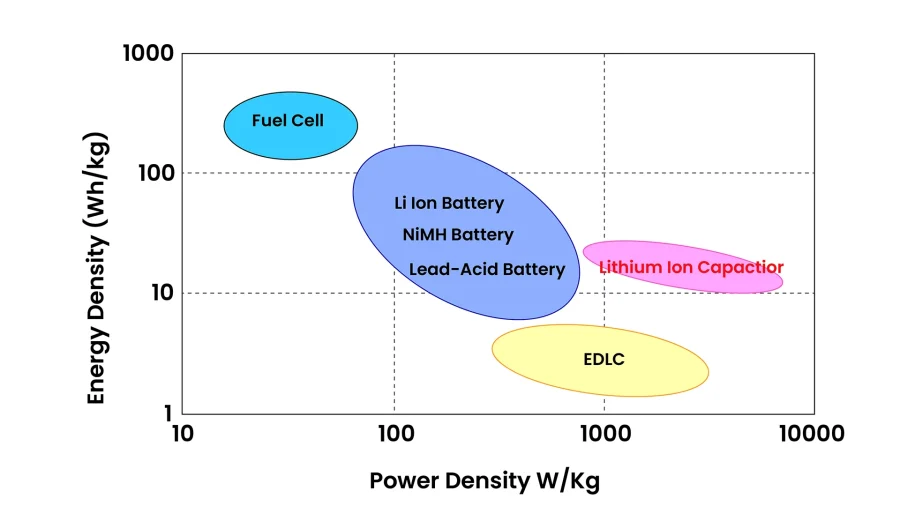

In custom battery pack design stage, many engineers face tough trade-off between high energy density and high power density battery. This results in two pain points: device’s battery life falls short while size and weight reaches structural limits, or battery system frequently restarts due to voltage drops under instantaneous high loads.

High energy density battery focuses on storing more energy to extend battery life, ideal for space-constrained and extended runtime devices, such as drones, robots and engines. High power density battery excels in fast energy discharge and recharge, suitable for high power in short term, such as power tools, defibrillators.

This article dives into high energy density vs. high power density batteries, covering differences, design strategies and the technology trends shaping the future of custom power solutions.

What Is a High Energy Density Battery?

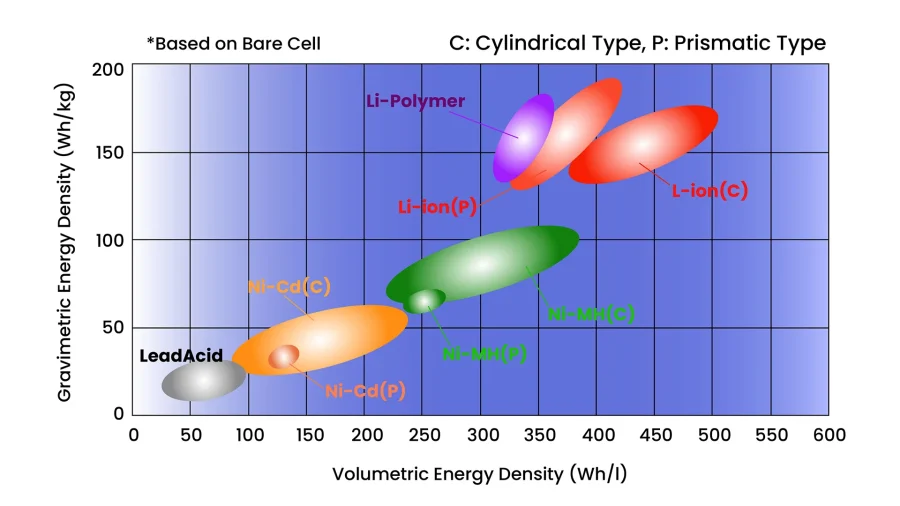

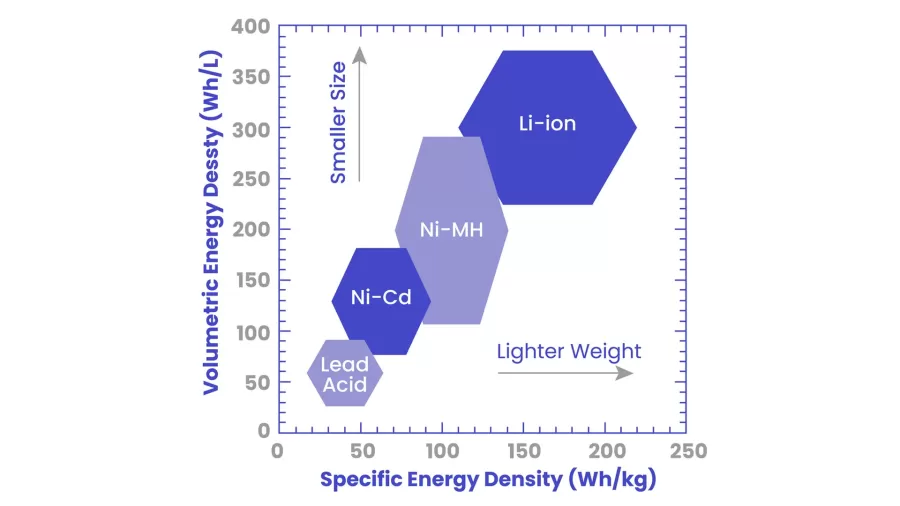

High energy density batteries store more energy within limited volume and weight per unit mass or volume, measured in watt-hours per kilogram(Wh/kg) and watt-hours per liter (Wh/L). Battery with higher Wh/kg or Wh/L rating features with higher energy density. High energy density batteries are used in devices requiring long-term, stable power supply. High-nickel NMC chemistry and solid-state battery technology are promising high energy density battery solutions. Energy density can be evaluated on gravimetric or volumetric, depending on the application.

- Gravimetric Energy Density: This refers to the amount of electrical energy that battery stores per unit of mass, measured in Wh/kg. This metric is vital for weight-sensitive devices, such as detection robots, RVs.

- Volumetric Energy Density means electrical energy amount that battery stores per unit of volume, measured in Wh/L. This metric is essential for space-constrained devices, such as smartphones and portable devices.

Strategies to Enhancing Battery Energy Density

Material selection, cell structure design, and manufacturing processes are factors that determine the energy density of lithium-ion batteries.

- Electrode Material. High-nickel NCM/NCA chemistry offers higher capacity and voltage platforms, achieving higher energy density than LFP. Silicon-based anode materials provide higher specific capacity than graphite.

- Increasing active material loading. Enhancing energy density by increasing electrode compaction density and coating thickness, while reducing inactive material content through thinner current collectors and separators.

Advantages of High Energy Density Batteries

- Enhanced Battery Life. High energy density batteries store more energy at the same weight or volume, extending device usage time.

- Lightweight and Compact Design. Advanced high energy density batteries reduce device weight, ideal for weight-sensitive applications. High volumetric energy-density batteries achieve larger capacity within limited space, enabling lightweight device.

- Reducing System Costs. High energy density batteries reduce the quantity of battery and materials, lowering battery system costs. Reducing battery weight and volume also lowers transportation and maintenance costs.

What Is a High Power Density Battery?

High power density batteries refer to batteries that rapidly release large amount of power per unit mass or unit volume, and are expressed in watts per kilogram(W/kg) and watts per liter(W/L). High power density battery delivers high current and power in a short period, suitable for devices demanding fast response and high power output, such as power tools, e-bikes.

Strategies to Improve Battery Power Density

- Electrode materials: High electronic and ionic conductivity with short ion diffusion paths, achieved through carbon-coated cathodes (e.g., carbon-coated LFP), smaller particle sizes, and optimized electrode porosity to reduce polarization resistance.

- Electrolyte: Electrolytes with high ionic conductivity and low viscosity minimize ohmic resistance, enabling fast ion transport during high C-rate and pulse discharge while maintaining electrochemical stability.

- Separator: Thinner separators with higher porosity and well-distributed pores shorten ion pathways and lower ionic transport resistance, though they require enhanced thermal and safety protection at the system level.

- Cell architecture and tab design: Thinner electrodes, multi-tab or tabless designs, and optimized current collectors reduce internal resistance and localized heating, improving high-power and pulse performance.

- Pulse vs. continuous power: Many cells support high pulse current but suffer voltage sag and heat buildup under continuous load. Power density must be defined based on real operating profiles, not peak ratings alone.

- Voltage sag and platform stability: Excessive internal resistance leads to sharp voltage drops under load, limiting usable energy and causing system instability—an issue that cannot be solved at the cell level alone.

- BMS and power path design: High power output demands fast BMS sampling, low Rds(on) MOSFETs, and proper thermal design; otherwise, the battery system—not the chemistry—becomes the performance bottleneck.

High power density is not achieved by a single parameter or component. It requires coordinated optimization of cell materials, internal structure, and pack-level electrical and thermal design, which is why high-power applications often rely on custom battery pack engineering rather than standard cells.

Advantages of High Power Density Batteries

- Rapid charge and discharge. High power density battery offers high current in short term to enhance efficiency, ideal for devices requiring instant power output, such as power tools.

- Strong high-load performance. High power density battery provides instant, powerful energy to meet high power demand. For instance, Autonomous Mobile Robot achieve strong acceleration and climbing.

- Smaller and lighter systems. Higher power output per unit volume reduces battery size, lowering system weight and improving maneuverability.

What is the Difference of High Energy Density vs. High Power Density Battery?

| Feature | High Energy Density Battery | High Power Density Battery |

| Metric | Watt-hours per kilogram(Wh/kg) and watt-hours per liter (Wh/L) | Watts per kilogram(W/kg) and watts per liter(W/L) |

| Definition | how much energy device contains | how quickly device discharge energy |

| Analogy | Marathon Runner | TankSprinter |

| Performance | Long-duration runtime | Instant power output and dynamic load response |

| Design Focus | Thick electrodes, high active material | Thin electrodes, full tabs, low internal resistance |

| Energy Capacity | Higher in size/weight | Lower in size/weight |

| Charge/Discharge Rate | Low C-rate to protect cycle life and avoid excessive polarization | High C-rate charging/discharging supports rapid energy flow |

| Applications | Energy storage systems (ESS), RVs, backup power | Power tools, robots, drones |

Table1: Features of High Energy Density vs. High Power Density Battery

Engineering Consequences of Choosing the Wrong Density Focus

In actual applications, prioritizing the wrong battery density metric often leads to system-level failures rather than minor performance gaps.

High energy density but insufficient power:

The battery may meet runtime expectations, but cannot support peak current demand. This typically results in voltage sag under load, triggering system resets, brownouts, or unexpected shutdowns, especially during startup or transient events.

High power density but insufficient energy:

The system delivers strong instantaneous performance, but overall runtime falls short. Devices may require larger or more frequent battery packs, increasing maintenance needs and compromising user experience.

Incorrect density trade-off:

Attempting to compensate through pack oversizing often leads to larger dimensions, higher weight, increased cost, and reduced design flexibility—without fundamentally solving the root cause.

In many cases, these issues only surface during late-stage testing or field deployment, making redesign costly and time-consuming. Selecting the right balance between energy density and power density at the pack and system level is therefore critical from the earliest design stage.

Energy Density VS. Power Density Metrics and Design Trade-offs

Performance gap between energy density and power density can be further summarized using four key metrics and cell-level design trade-offs.

| Metric Category | Dimension | Unit | Engineering Focus | Typical Application |

| Energy Density (Endurance) | Gravimetric | Wh/kg | Specific Energy: Determines the runtime per unit of weight. | Drones, Heavy-duty truck. Reducing weight increases payload, profitability. |

| Volumetric | Wh/L | Space Efficiency: Determines how much energy fits in fixed volume; affects device thinness. | Smartphones, Wearables: Maximizing range within constrained space. | |

| Power Density (Burst) | Gravimetric | W/kg | Power-to-Weight Ratio: Determines the ability to overcome gravity for rapid acceleration. | Racing Drones, eVTOL: Pursuing instantaneous power with minimal mass. |

| Volumetric | W/L | Power Compactness: Measures max energy release within tiny footprint. | Power Tools, Portable Medical Devices: Delivering high torque from small enclosures. |

Table2. Four Metrics of High Energy Density vs. High Power Density Battery

| Battery Component | High Energy Density Battery | High Power Density Battery | CMB Engineering Review |

| Electrode Coating | Thick coating | Thin coating | Thick coatings maximize energy but increase IR; Thin coatings enable fast kinetics. |

| Porosity | Lower porosity | Higher porosity | Lower porosity slows ion diffusion; higher porosity prevent voltage sag under high loads |

| Particle Size | Medium to large | Medium to small | Smaller particles increase active surface area and enables high-current delivery. |

| Conductive Carbon | Less | More | Robust conductive network minimizes heat and maximizes brust power output |

| Current Collector | As thin as possible | Thicker | Thicker foils handle high current density and mitigate thermal stress |

| Tab Design | Narrow, fewer tabs | Wider, multiple tabs | Full-tab designs ensures even current distribution, eliminating battery localized heat |

| Electrolyte | High ionic conductivity | Enhanced rate-type | Stable electrolyte chemistry prevents decomposition during rapid discharge |

Table3 Key Cell-Level Design Trade-offs: Energy Density vs. Power Density

Why Cell-Level Optimization Alone Is Not Enough

Cell datasheets describe ideal performance under controlled test conditions, but real-world battery systems operate under complex electrical, thermal, and safety constraints. As a result, strong cell-level specifications do not always translate into reliable system-level power output.

At the battery pack level, achievable power is often limited by factors beyond the cell itself, including:

Busbar and interconnect design:

Inadequate conductor sizing or layout increases resistance and localized heating, reducing usable power during high-current discharge.

Thermal path efficiency:

Even high-power cells derate quickly if heat cannot be dissipated effectively, leading to current limiting or early voltage collapse.

BMS current logic and response speed:

Protection thresholds, sampling rates, and control algorithms directly affect how much power can be safely delivered, especially during transient loads.

Safety margins:

To ensure long-term reliability and compliance, current, temperature, and voltage limits are often conservatively set, further reducing real usable power.

A common example:

A battery pack built with high power-rated cells may perform well in short lab tests, yet experience voltage sag or system resets in the field when simultaneous current spikes and temperature rise trigger BMS protection—despite the cells operating within their datasheet limits.

This gap between cell ratings and real system behavior is why many OEMs turn to custom battery pack design rather than off-the-shelf solutions when balancing energy and power requirements.

Battery Types Selection by Energy Density and Power Density

High Energy Density Battery Types

High-Nickel Ternary Lithium-ion Batteries(NMC Battery): NMC battery boasts 250-300 Wh/kg high energy density by increasing the nickel content in the cathode material, such as NCM811, NCA. However, high-nickel materials stability can be improved through surface coating and doping techniques. It emerges as popular choice for robot thanks to lightweight design and extended battery life.

Solid-state lithium batteries use optimized solid electrolytes, such as oxides, sulfides and interface engineering improve ionic conductivity, offering higher safety, thermal stability and energy density. In October 2025, Sunwoda unveils next-gen solid-state battery with 400 Wh/kg energy density.

High Power Density Battery Types

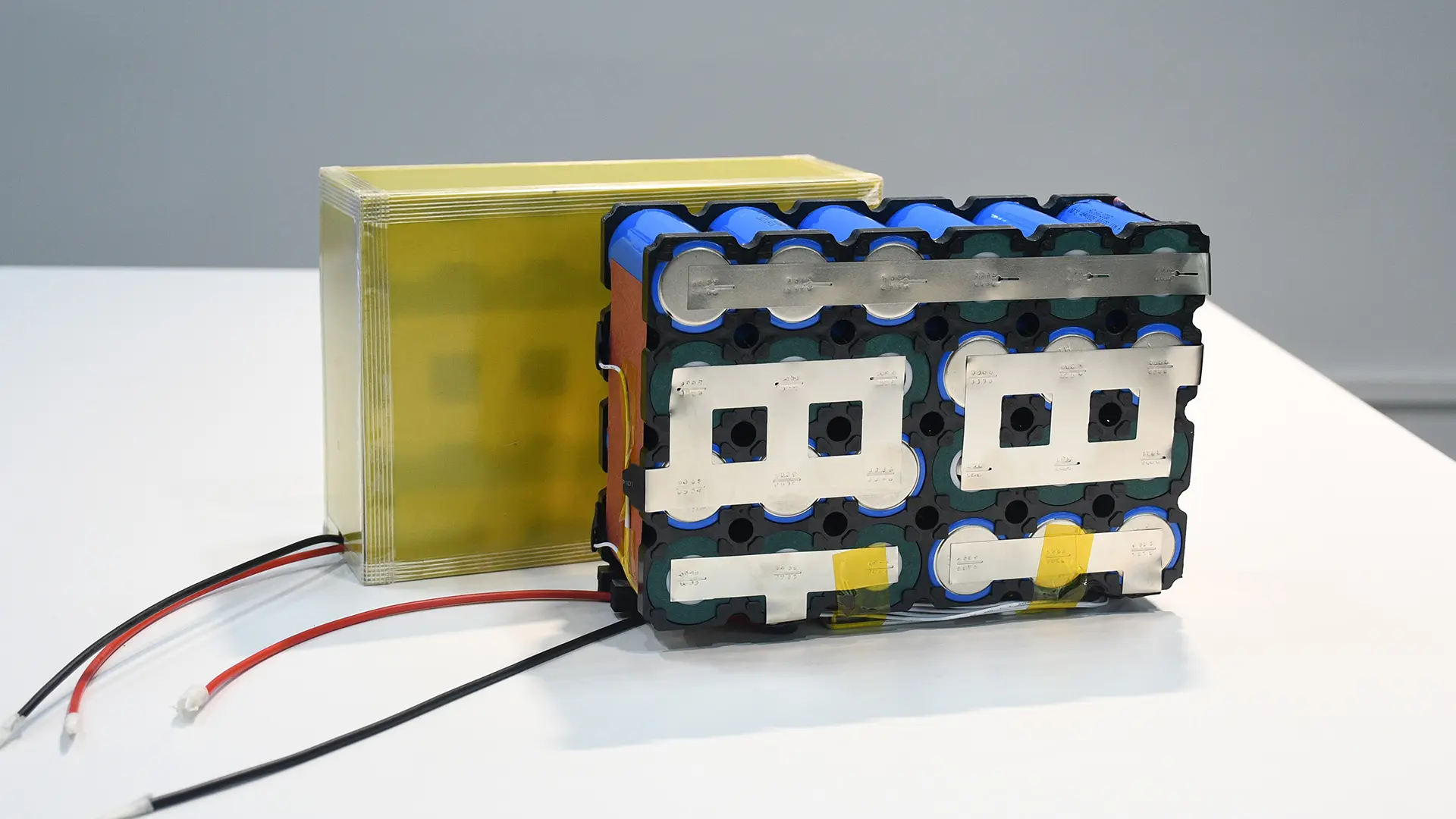

Full-tab battery uses the positive and negative current collectors as tabs, shortens current transmission path, reduce internal resistance, and achieve uniform current distribution, improving high-rate charge and discharge capabilities. It becomes an innovative choice of thruster motors, power tools and eVTOL. A press from globenewswire unveils that BAK all-tab 18650 and 21700 cylindrical batteries reduces 70% internal resistance, improves 100% discharge capability and 30% discharge time under high-rate discharge.

Stacked lifepo4 cell with multi-tab design increases current collection points, shortens current transmission distances, providing stable discharging capability. Stacked cell process creates uniform current paths, reduces polarization during electron and lithium-ion migration. It supports fast charging and high-rate discharge.

High Energy Density vs. Power Density Battery: Which is Right for You?

Choosing between high energy density and high power density batteries depends less on specifications and more on how your device actually operates. The key is to match the battery’s strength to your application’s dominant load profile.

When to Choose High Energy Density Battery:

- Long running time with moderate load: Aerial photography drones need high energy density to get the most flight time and charge less often, even though they don’t need a lot of power at peak times.

- Strict space and weight limits: Mobile and quadriped robots need light battery systems to reduce joint stress and improve mobility. This makes energy density a very important design goal.

- Stable, continuous power output: Communication system rack-mounted lithium-ion batteries like high energy density to support long-term operation while removing bulky lead-acid batteries.

The design goal was to get the most useful energy out of a limited amount of space and weight while keeping the voltage stable over a long discharge.

When to Choose High Energy Density Battery:

High power density batteries are essential when devices demand fast response and high current over short periods.

- Rapid acceleration and startup. ProCORE 18V+ power tool adopts 21700 full-tab battery design to achieve high torque output and instant high power.

- Rapid charging and discharging. UPS require batteries that charge and discharge quickly to respond to instantaneous power fluctuations in the grid or to provide emergency power.

- Intermittent high-power output scenarios and quick response. Industrial equipment often requires bursts of high power during operation.

Reducing internal resistance, managing voltage sag, and guaranteeing thermal stability under high current are the main design goals.

When the Choice Is Not Either-Or

Many modern applications—such as advanced robotics, medical devices, and intelligent industrial systems—require both long runtime and high peak power. If your application falls between these categories, a hybrid design approach that balances energy density and power density at the pack level is often required.

Can Battery Achieve Both High Energy and High Power?

High energy density and high power density battery are two restrictive indicators. High energy density relies on thick electrodes and high loading of active materials, but this lengthens ion transport pathways and reduces charging and discharging speeds. Conversely, high power density requires thin electrodes and low internal resistance design, which compromises energy storage capacity. In addition, high capacity materials and high-rate conditions place demands on thermal management, forcing engineers strike balance between energy, power, and safety.

Conclusion Energy vs. Power: Precision Engineering

The optimal selection between high energy density and high power density depends on the specific duty cycle and operational environment of the application. Utilizing high-nickel NCM (Lithium-ion) for energy capacity and advancing Solid-State technology for enhanced safety and energy thresholds.Tabless cell designs to minimize internal resistance for high power density. Dedicated BMS protocols and thermal management to enhance stability and safe operation. Consult CM Batteries’ professional engineering team for advanced custom battery solutions.

Reference Sources

1. Optimization of lithium-ion battery designs considering energy density and rate capability proposes adjusting design parameters such as cathode area capacity, cathode-to-negative electrode ratio, porosity, and operating temperature to improve energy density and rate capability.

2. Battery types and recent developments for energy storage: Compare energy density and power density of various battery types, including lead-acid, nickel-based, lithium-ion, and future solid-state batteries.

3. Simulation study on the interaction between the battery module and busbar: Demonstrates that busbar design (thickness, length, material) affects resistance and heat generation, affacting temperature rise and high-current performance.