Custom Battery Pack Manufacturer: Powering Your Innovations

CMB is a custom battery pack manufacturer specializing in the design and production of high-performance lithium-ion battery packs customized for the world’s most demanding industrial applications, extreme working environments, and extreme temperatures. We are proud to be a pioneer of the power solutions of the future. Explore our range of custom lithium-ion battery pack solutions and discover how CMB energizes your industrial innovations.

Custom Battery Pack Manufacturer for Tailored Solutions

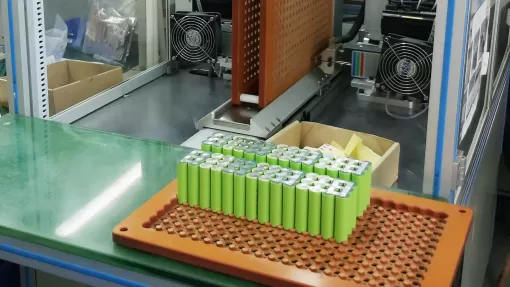

Custom 18650 Battery Packs

Why Choose CMB As Your Custom Battery Pack Manufacturer?

Our Engineering Team

CMB boasts a highly skilled and experienced customized battery pack engineering team led by a CTO with over 15 years of experience in lithium-ion battery technology with industry giants CATL, BYD, and BAK. Our team of 5 specialized engineers brings diverse skills in design, manufacturing, testing, and quality control. Together, our team has completed over 800 specialist battery pack design projects across various industries, demonstrating our commitment to continuous innovation in custom battery design solutions.

Our Quality Control Strategy

CMB’s quality control is supervised by co-founder Max Lee and follows ISO 9001:2015’s requirements for quality management systems. All departments are involved in this process, ensuring adherence to industry standards and customer expectations through strict control of our supply chain, manufacturing process, and quality management. We also use a digital monitoring system for additional quality control.

Our Certification

CMB is committed to maintaining the highest standards of quality and safety in our li-ion battery pack manufacturing. Our certifications demonstrate our adherence to international standards and regulations, ensuring that our products meet or exceed industry requirements. These certifications reflect our dedication to producing reliable, safe, and high-performance custom built lithium battery pack solutions for our clients.

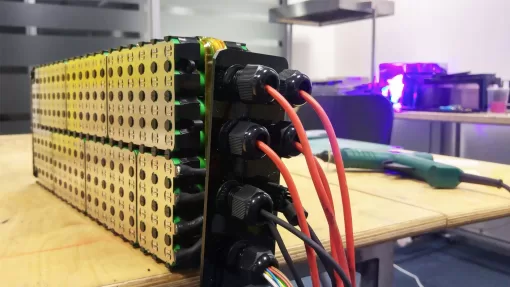

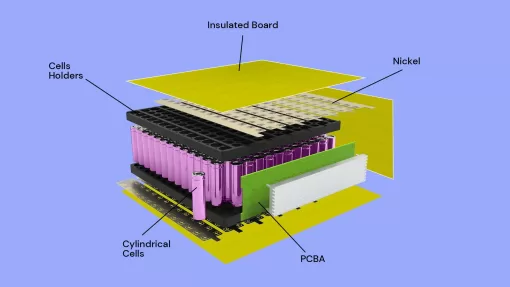

Our Battery Pack Assemblies Process

CMB’s custom battery pack assembly services involve evaluating battery chemistries, casing design, and management systems based on customer needs. The process encompasses basic and advanced lithium battery pack design features, each tailored to meet specific requirements. This includes intrinsically safe designs for harsh environments, custom battery chargers, custom molded enclosures up to IP68 for extreme protection, and complex battery management systems to ensure safety and longevity.

Lithium-ion battery pack manufacturing process includes separate cell sorting, assembly, and insulation stages to ensure high performance, safety, and longevity for all of our custom rechargeable battery packs.

Our Efficient Service

At CM Batteries, we serve our customers at every stage of their custom li ion battery pack journey, offering a user-friendly experience from initial concept to final product delivery. Our dedicated international sales team works diligently to prevent communication barriers for our global clients, ensuring a smooth and efficient process for all, regardless of location or language differences. All of our departments work together as a team to make sure that any client problems get resolved as quickly and efficiently as possible.

CMB Custom Battery Pack Applications

Tailored Customization

Our design team can create custom battery designs for just about any device or machine.

Timely Delivery

Our efficient production and distribution process gets your product delivered in a timely manner.

Quality Guarantee

We stand by our products and guarantee you’ll be happy with your purchase.