As experts in custom battery pack design, we understand the intricate details that go into creating high-performance and reliable power sources for various electronic devices. Let’s delve deeper into the factors that shape the design of lithium-ion battery packs and how they influence the performance and safety of your applications.

Basic structure of lithium-ion battery pack

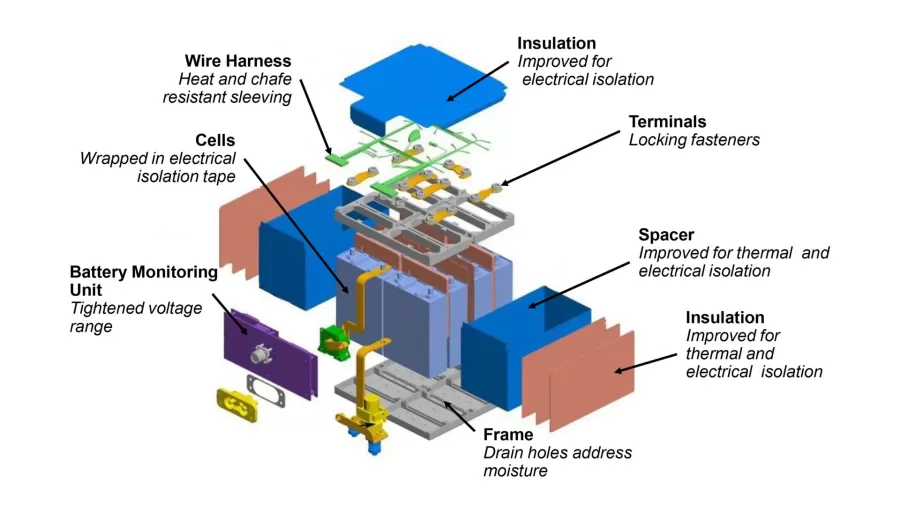

A lithium-ion battery pack’s fundamental structure consists of many key components that work together to store and transfer electrical energy efficiently and safely. Let us break down the important elements:

Positive Electrode (Cathode): The positive electrode is usually composed of lithium metal oxides, such as lithium cobalt oxide (LiCoO2), lithium manganese oxide (LiMn2O4), or lithium iron phosphate (LiFePO4). These materials serve as a source of lithium ions during battery operation.

Negative Electrode (Anode): The negative electrode is often made of graphite, which enables the intercalation and de-intercalation of lithium ions during charge and discharge cycles.

Separator: The separator is a microporous membrane that sits between the positive and negative electrodes, preventing direct contact yet allowing lithium ions to be transported. It is critical to prevent short circuits within the battery.

Electrolyte: The electrolyte is a conductive solution containing lithium salts (such as lithium hexafluorophosphate, LiPF6) dissolved in a mixture of organic solvents. It facilitates the movement of lithium ions between the electrodes during the charging and discharging processes.

Shape: Battery packs can be round or square in design to accommodate the space requirements and power needs of different devices.

Stacking and Winding: The electrodes of the battery can be assembled by stacking (layers on top of each other) or winding (similar to a reel) to increase the capacity and power output of the battery.

Cell Casing: The battery cells are enclosed within a protective casing, typically made of metal such as aluminum or steel. This casing provides structural support, and electrical insulation, and protects the cell components from external damage.

Terminal Connections: The positive and negative terminals of the battery pack are connected to external circuits through conductive tabs or wires. These connections allow for the flow of electrical current to power devices or recharge the battery.

Thermal Management System (Optional): In some advanced battery packs, a thermal management system may be integrated to regulate temperature during charging and discharging, enhancing safety and performance.

Battery Management System (BMS): For more sophisticated battery packs, a BMS is employed to monitor cell voltage, temperature, and current flow. It helps balance cell voltages, prevents overcharging or over-discharging, and ensures the overall safety and longevity of the battery pack.

Lithium-ion battery packs may fulfill particular energy storage needs, provide dependable performance, and maintain safety standards across a wide range of applications provided they are correctly designed and integrated. From the battery pack design engineer guide, advanced production procedures and material selection are critical in increasing the efficiency and longevity of these battery packs. What Influences the Structural Design of Lithium-Ion Battery Packs?

As a leading supplier of bespoke battery packs, CM Batteries digs into the complex realm of custom battery pack design. Our dedication to technical excellence motivates us to investigate and comprehend the important variables that impact the structural design of these powerhouses. Let’s go on a trip to discover the unique characteristics that create our cutting-edge battery solutions.

Battery Cell Characteristics

1. Discharge Characteristics Trend

The discharge curve trend, especially the slope of the discharge curve, significantly impacts battery pack design. Different battery cell types exhibit distinct discharge trends, influencing power delivery throughout the discharge cycle. Batteries with a sloping discharge curve experience gradual power reduction, posing challenges for high-power applications toward discharge completion. In contrast, low-power applications requiring stable voltage output may necessitate voltage stabilizers if the discharge slope is steep.

2. Environmental Temperature

Environmental temperature plays a crucial role in lithium-ion battery pack discharge characteristics. Operating in temperatures below 0°C can cause electrolyte freezing or significant performance reductions. Design considerations must account for temperature effects on battery efficiency and longevity. Optimal performance is often observed within specific temperature ranges, where higher temperatures enhance capacity and reduce internal resistance, thus improving cycle life. Deviations from optimal temperatures can impact overall battery cycle longevity.

3. Pulse Capability

The ability of lithium-ion battery packs to deliver high-current pulses is a critical factor, especially for applications requiring sudden power surges. Pulse performance depends on electrode surface area, and current limits are influenced by internal chemical reaction rates. Understanding cell-level pulse capabilities aids in designing battery packs that meet specific power delivery requirements while ensuring long-term reliability.

Battery Pack System Design Considerations

1. Waterproofing and Explosion-Proof Design

In the design of lithium-ion battery packs, waterproofing and explosion-proof features are paramount for safety and longevity. Battery packs must meet stringent waterproofing standards to prevent water ingress, which can damage internal components. Additionally, integrating explosion-proof valves helps manage internal pressure changes during charge and discharge cycles, ensuring pack safety.

2. Maintaining Pressure Balance

Achieving internal and external pressure balance within lithium-ion battery packs is critical for stability and safety during operation. Breathable yet waterproof explosion-proof valves are essential components to maintain pressure equilibrium, mitigating safety risks associated with pressure differentials.

3. Lithium-Ion Battery Management System (BMS) Design

Effective battery pack design incorporates robust Battery Management Systems (BMS) to monitor and control charging, discharging, and temperature conditions. Precision testing and cell balancing capabilities within the BMS optimize battery performance, safety, and longevity.

4. Mechanical and Electrical Design

Balancing mechanical robustness with electrical efficiency is paramount in battery pack design. Considerations include structural integrity, shock resistance, heat dissipation, and adherence to safety and electromagnetic compatibility standards.

5. Waterproofing and Shock Resistance

Enhanced waterproofing and shock resistance are critical for battery packs operating in challenging environments. Custom designs cater to insulation requirements between electrodes, ensuring safety and reliability across diverse conditions.

Material Selection

High-Voltage Insulation Performance

Material selection for lithium-ion battery pack structures focuses on high-voltage insulation performance. Common materials such as high-strength nylon with fiberglass reinforcement enhance structural strength and vibration resistance, ensuring long-term reliability.

You can get the battery pack design guide from CM Batteries, our comprehensive understanding of these specialized factors enables us to craft bespoke lithium-ion battery packs tailored to your specific needs. We integrate advanced technologies, rigorous testing, and safety protocols to deliver cutting-edge energy solutions that power your innovations reliably and efficiently. Let us empower your projects with energy solutions that surpass expectations in performance, safety, and durability.