Alongside the growing demand for automotive IoT, the eCall system has emerged as an integral component to enhance vehicle safety and reliability. This drives the rapid demand for durable and long-lasting ecall batteries. What are the challenges and solutions in customizing a suitable eCall battery? This article explores the features and design considerations behind an effective eCall battery.

What is an eCall Battery?

Defination

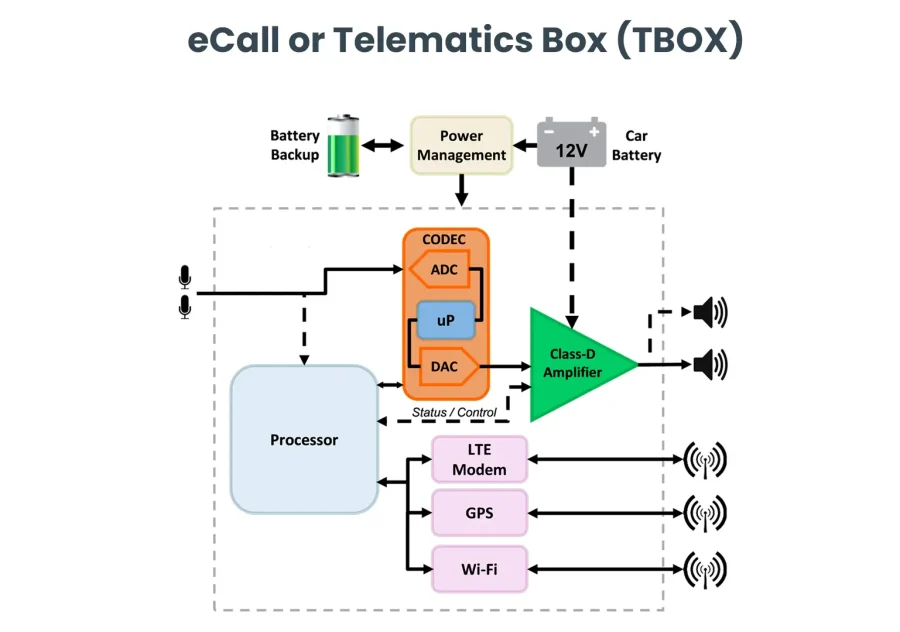

The eCall (Emergency Call) system is an emergency call system for vehicle accidents launched by the European Union. It is mainly used to automatically or manually send a vehicle’s location and critical data to the PSAP (Public Safety Answering Point) for help. Thus, eCall batteries serve as backup power for the eCall system when the main power fails.

Function

The eCall battery is the critical component of the eCall system in ensuring continuous power.

- eCall battery refers to the backup battery that provides power support for the eCall system when the vehicle’s main power fails.

- eCall battery ensures the system triggers emergency calls, transmits location and crash data, and maintains voice communication after an accident.

UN Regulation No.144 (Rev.1) emphasizes that this backup power stays not least 5 minutes in voice mode and 60 minutes in call-back mode before the crash, and supplies power to the eCall system after the crash. Therefore, understanding eCall battery types and challenges is vital before making a decision.

How eCall Regulations Drive the Demand for Advanced Battery Solutions?

In February 2024, the European Union issued two documents on e-Call systems—EU 2024/1180 and EU 2024/1184—promoting the evolution of e-Call from CS-eCall to NG-eCall.

High-temperature-resistant, long-lasting, and high-energy-density lithium-ion batteries are preferred for the next generation of eCall systems.

The following chart shows the regulatory updates for the eCall system. Then, I conclude the battery design requirement based on these changes.

| Upgrade Direction | Technical Change Description | eCall Backup Battery Design Requirements |

| Communication Network(2G/3G→4G/5G) | Network access type shift from GSM/UMTS to LTE/5, offering faster rate and stronger real-time | High energy density Stable voltage output |

| Signaling System (SS7/ISUP→SIP (IMS)) | Full IP-based signaling More complex data interaction | Low internal resistance Fast response for transient current |

| Voice & Data Channel (Single voice→Voice + data concurrent) | IMS enables concurrent voice & data. Longer communication duration | High discharge rate Continuous power supply |

| MSD Transmission (In-Band to Out-of-Band Communication) | Higher out-of-band rate Stronger anti-interference | Stable voltage under high-frequency communication to prevent disconnection |

| Network Handoff (GSM/UMTS→4G/5G adaptive) | Supports handoff & cross-standard compatibility at high speed | Reliable power supply under short-term current fluctuations |

| PLMN Support Requirements Increase | Supports IMS emergency calls MSD updates | Low self-discharge rate Excellent capacity retention |

| Environment& Adaptability | Higher 4G/5G module power consumption. Greater thermal stress | Wide temperature range (-40℃~+85℃) resistance Vehicle-grade safety certification |

How to Choose the Best Battery Type for Your eCall System?

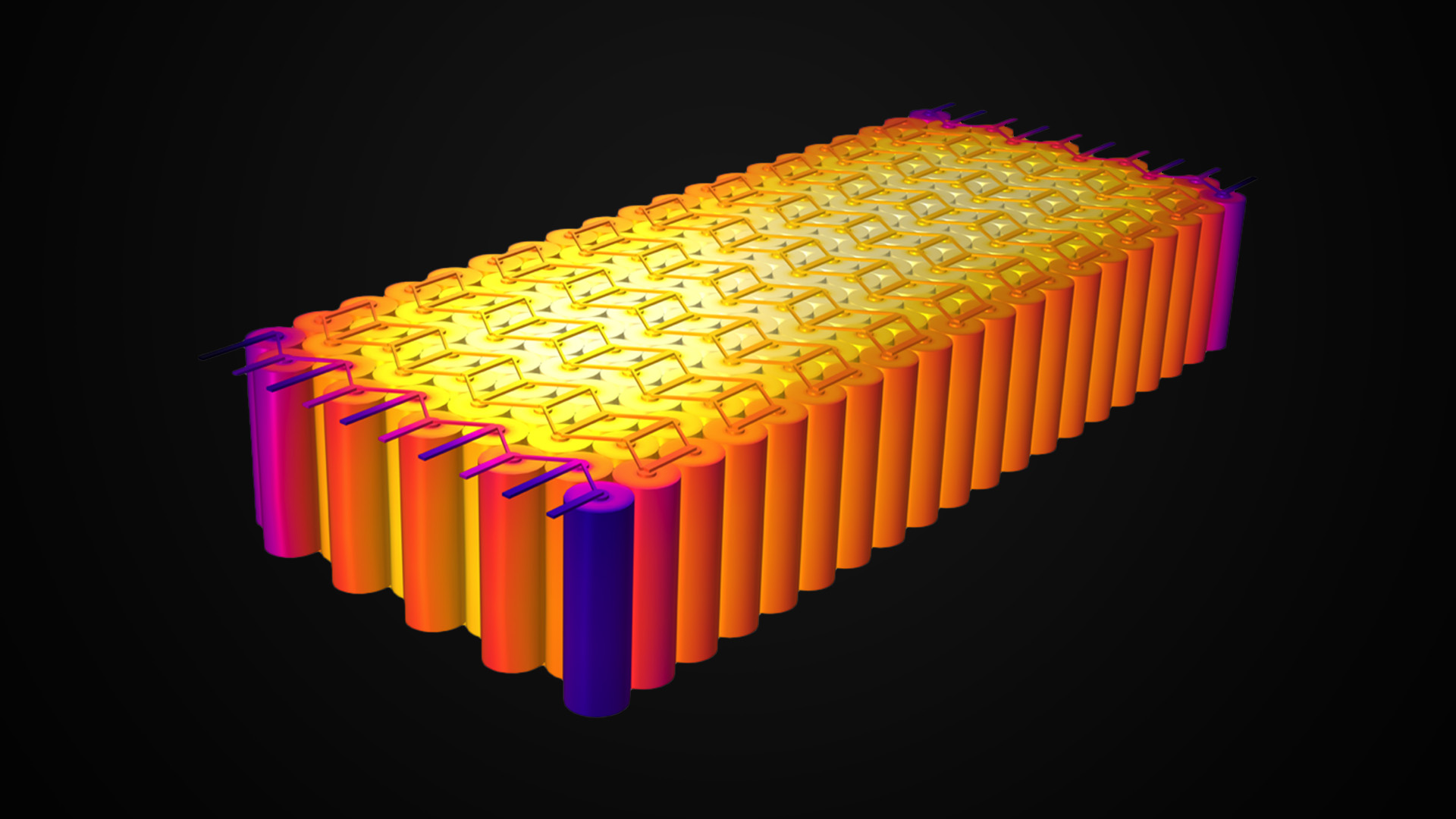

The new generation of eCall (NG-eCall) is moving towards 4G/5G and IMS technology, thus promoting the selection of eCall batteries has shifted from the early low-power NiMH batteries to advanced lithium-ion batteries and lithium iron phosphate batteries. Here I draw a table to compare their chemistries, features, and pros and cons.

| Battery Type | Chemistry | Key Feature | Pros | Cons | Typical Use in eCall |

| LiFePO4 (Lithium Iron Phosphate) | LiFePO4 | 3.2 V nominal. Stable chemistry | Excellent thermal stability. Long cycle life | Needs protection circuit. Battery aging under overheating | For systems needing stable temperature tolerance (–40 °C ~ +85 °C) |

| High-Temperature Lithium-ion Battery | Lithium-ion | –40 °C ~ +85 °C operation | Great heat resistance. Stable capacity retention | Higher cost | Long Standby and Wide Temperature Range Application |

| Li-ion (Lithium-ion) | LiCoO2/NMC | 3.6–3.7V nominal | Compact size, high energy density | Limited high temperature tolerance | Space-constrained eCall modules |

| NiMH (Nickel-Metal Hydride) | Ni-MH | 1.2 V nominal per cell | Low cost. Moderate temp tolerance | Lower energy density, high self-discharge | Used in early CS-eCall systems; Gradually replaced by lithium cells |

What Are the Main Challenges in eCall Battery Design?

eCall batteries work when a vehicle accident occurs, so their major features include superior safety, high energy density, wide temperature performance, compact design, and strong power output.

Long-Life and Safety Reliability Requirements

Extended cycle life. eCall batteries operate in a long-term float charge state. Battery self-discharge and active material aging can affect the battery’s usable capacity. Maintaining the battery’s sufficient usable capacity throughout the vehicle’s lifecycle is critical.

Safety and reliability. Batteries must remain safe and stable under extreme conditions, such as vehicle collisions, high temperatures, and humidity. They can handle safety hazards such as thermal runaway, fire, and explosion.

Temperature Adaptability Challenges

These challenges are all about the battery’s chemistry and physics, especially when things get really hot or really cold.

1. Low-Temperature Challenge (e.g., -20°C to -40°C / -4°F to -40°F)

The electrolyte gets sludgy and slow: At low temperatures, the electrolyte inside the battery becomes thick or even starts to solidify, making it harder for lithium ions to move freely.

A huge spike in internal resistance: Because ion movement slows down, the battery’s internal resistance rises dramatically.

The Consequences:

Insufficient starting voltage or pulse current: This is the biggest failure point. In a crash, a cold battery might not be able to provide the quick, powerful jolt needed to fire up the cellular and GPS modules. The call might fail, or the signal could be too weak.

“Fake” capacity readings: While the battery might still power low-current standby modes, its usable capacity drops significantly during high-current discharge. That means it might not last long enough for a full eCall session, which usually needs to run for several minutes.

2. High-Temperature Challenges (e.g., +60°C to +85°C+ / 140°F to 185°F+)

Electrolyte breakdown and accelerated side reactions. High heat speeds up unwanted chemical reactions inside the battery, causing electrolyte decomposition, gas generation, and reactions with electrode materials.

Active material degradation and increased resistance. Prolonged exposure to heat damages the electrode’s active materials and forms thicker, resistive surface layers (known as SEI films), which make it harder for ions to pass through.

Higher self-discharge rate. At high temperatures, the internal chemistry becomes overly active. Even without any load, the battery’s charge drains quickly. For long-standby systems like eCall, this is disastrous—after a few years, the battery may lose too much charge to function.

Safety concerns. Constant heat greatly increases the risk of thermal runaway, leading to swelling, leakage, or even fire—especially inside confined spaces like a vehicle cabin.

3. The Temperature Cycling Challenge (Going from Hot to Cold and Back)

Cars experience daily and seasonal temperature swings, so the battery is constantly expanding and contracting.

Physical stress on materials: This repeated expanding and contracting physically stresses the battery’s internal parts. It can cause tiny cracks in the materials, make coatings flake off, and weaken connections. This leads to permanent loss of capacity and performance.

Unstable electrode-electrolyte interface: The protective SEI layer between the electrode and electrolyte breaks and reforms with each temperature shift. This repetitive process consumes active lithium and electrolyte, speeding up battery aging and shortening its overall lifespan.

Energy Density, Power Capacity, Volume Constraints

High energy density. eCall battery needs to offer strong energy with its limited size, supporting functions such as voice communication, GPS positioning, and data transmission functions.

Superior power output ability. The system requires a battery delivering robust power output to drive communication modules, sensors in the entire eCall system.

Limited Space. Battery volume must fit in the limited automotive space; hence, advanced custom design is vital.

To address the challenges described above, CM Batteries has designed a wide temperature battery technology for a custom eCall battery pack.

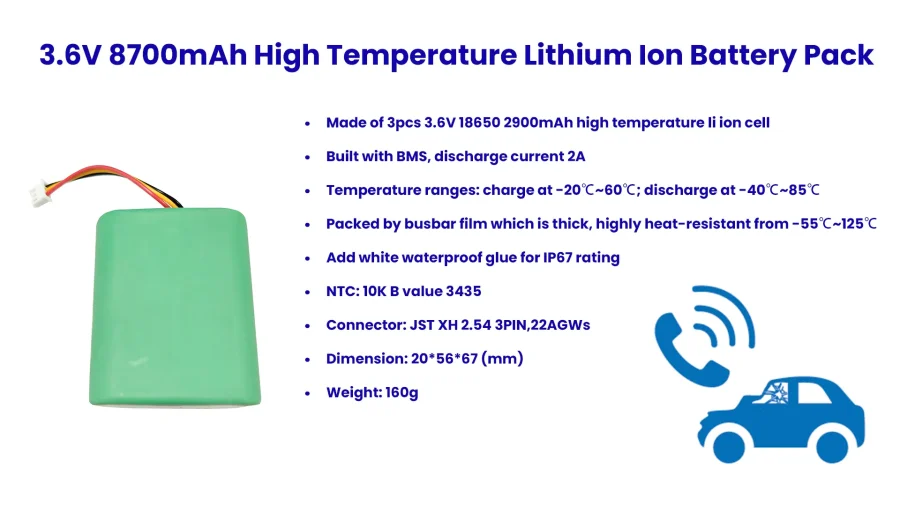

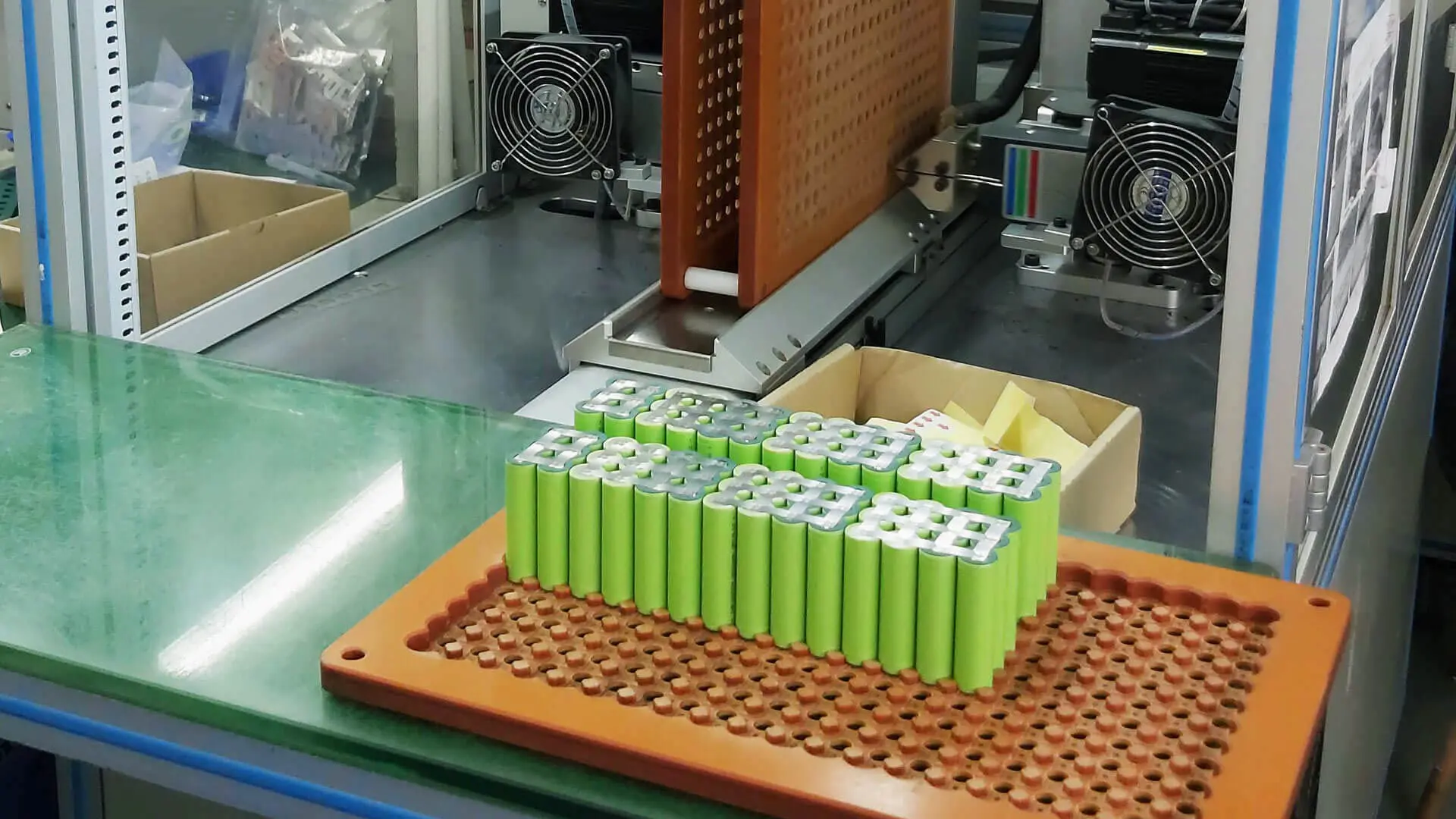

Case Study: 3.6V 8700mAh 1S2P High Temperature Battery for eCall System

When an automotive electronics manufacturer approached us looking for a high-temperature battery for their eCall emergency system, the requirements were clear — but extremely tough. The battery needed to operate reliably in both freezing winters and scorching cabin heat, deliver instant power for communication modules, and last for years in standby mode.

That’s where our 3.6V 8700mAh 1S2P high-temperature Li-ion battery pack came in.

Customer requirements

In-vehicle eCall systems are safety-critical devices that must activate instantly in the event of a crash — even after sitting idle for years. The customer’s biggest concerns were:

What ensures consistent power from -40°C to +85°C?

How to prevent battery degradation caused by repeated heat cycles?

How to maintain a reliable voltage for quick pulse discharge when the system triggers?

Most standard Li-ion batteries couldn’t handle this combination of long-term standby, high temperature, and instant activation.

The Solution & Key Design Highlights

Wide operating temperature: Delivers stable performance from -40°C to +85°C, ensuring reliable starts even in the coldest or hottest conditions.

High-temperature-resistant packaging: Built to withstand -55°C to +125°C, far beyond typical industry limits.

Excellent capacity retention: Maintains ≥70% capacity under extreme conditions (compared to the market average of ~55%).

Fast pulse response: Supplies quick bursts of current for eCall activation without voltage drops.

IP67 protection: Fully sealed design keeps out dust and moisture, ensuring safe operation in harsh automotive environments.

Integrated BMS and NTC sensors: Continuous monitoring against overcharge, over-discharge, and overheating ensures long-term safety and reliability.

What’s the Market Trend of eCall System Backup Battery?

The mandatory use of eCall systems in the European Union drives the increasing demand for reliable eCall backup batteries. Market report indicates that the global emergency eCall backup battery market is expected to grow at a CAGR of 10.2% from 2026 to 2033. Let’s focus on some new technologies and hot topics about eCall batteries.

Environment and Regulatory. The European Union’s REACH and Battery Directive 2023/1542 highlight the safety of battery disposal and usage. Thus, eCall battery manufacturers should investigate the supply chain, regulate battery passport information, and mark the capacity, recycling symbol. Furthermore, it is significant to restrict the use of hazardous substances and utilize eco-friendly battery materials, thus benefiting the environment.

Batteries need higher reliability, energy density, and temperature tolerance. eCall systems are evolving from traditional CS-eCall to NG-eCall, placing higher demands on battery performance. Future eCall batteries will need to have wider temperature adaptability, longer storage life, and higher energy density to meet the real-time data transmission and voice call requirements of NG-eCall systems.

Conclusion

Overall, the evolution of eCall systems under the EU’s new 2024 regulations has raised the bar for backup battery performance in automotive safety applications. As vehicles move from 3G to 4G/5G networks and integrate more complex data and voice functions, eCall batteries must now deliver higher energy density, faster pulse response, and wider temperature adaptability.

The eCall battery plays a critical role in automotive safety. Its design must meet stringent regulatory and performance standards to power the next generation of intelligent, connected vehicles. Have questions or special requests? Our team is always ready to help — because at CM Batteries, every battery is custom-built for your needs.