At CM Batteries, we are open to making li-ion battery pack design and development transparent to our customers from battery pack concept to prototype. Each process’s transparency boosts efficiency and reliability.

Lithium ion Battery Pack Concept

- We design battery packs with LiFePO4,18650,21700 and lithium polymer rechargeable battery types. The brands and models of cells are marked clearly in your li-ion battery pack solution.

- BMS solutions including components BOM are public. You can contact your particular sales consultant to get more details.

- The final version battery pack solution with the exact dimension, voltage, capacity, discharge current, connector, and wire specification.

- The sketch of the battery pack drawing is available to offer.

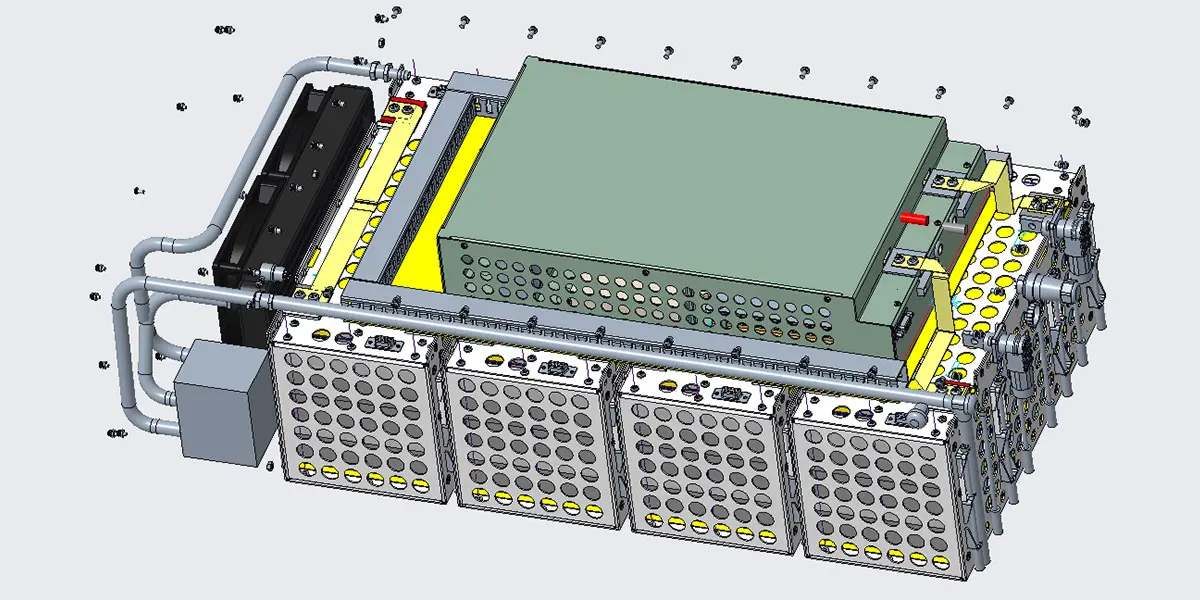

Li ion Battery Pack Technology

CMB employs advanced battery pack technology to boost reliability in high discharge current, heat, insulation, and cycles.

Our engineering team has professional and excellent Li-ion battery chemistry knowledge. Before each cell’s models are assembled as custom battery packs, we will test the cycles, discharge charge performance, and temperature with hundreds of times.

We have 4 cooling methods to reduce the heat. Each cooling method will affect the cost. Visit more.

As one of the specialist battery pack manufacturers, we are focusing on custom battery packs for commercial and industrial applications with high discharge and high voltage. We design unique BMS and contractor solutions for each custom battery pack solution.

Tailored Customization

Our design team can create custom battery designs for just about any device or machine.

Timely Delivery

Our efficient production and distribution process gets your product delivered in a timely manner.

Quality Guarantee

We stand by our products and guarantee you’ll be happy with your purchase.