In today’s fast-paced world, custom battery packs power a wide array of electronic applications, from medical devices and industrial equipment to consumer gadgets. To ensure their optimal performance, safety, and longevity, the design and compatibility of custom Lithium ion battery charger are critical. This article delves into the key technologies and industry solutions driving advancements in custom battery charging systems.

Charging Characteristics of Different Battery Chemistries

Battery technology has undergone significant advancements over the years, evolving from early Nickel-Cadmium (NiCd) batteries to modern Lithium-Ion (Li-ion) and Nickel-Metal Hydride (NiMH) batteries. Each type of battery chemistry has unique characteristics and specific charging requirements to ensure safety, efficiency, and longevity.

NiCd and NiMH Batteries Charging Characteristics

Batteries like Nickel-Cadmium (NiCd), Nickel-Metal Hydride (NiMH), and Lithium-Ion (Li-ion) often rely on the constant current (CC) charging method. This approach ensures a steady flow of current during charging, making it suitable for a wide range of applications. However, the process requires precise current control and prompt termination when the battery reaches its full voltage.

Lithium-Ion Batteries Charging Characteristics

Lithium-ion (Li-ion) batteries require a constant voltage (CV) charging method as a critical part of their charging process. Strict voltage control during charging is essential to ensure safety, extend battery life, and prevent overcharging, which can lead to safety risks such as overheating or thermal runaway.

Charging Characteristics of Lead-Acid Batteries

Lead-acid batteries are valued for their reliability and versatility in various applications. These batteries perform exceptionally well in float charging setups, which are ideal for maintaining capacity over extended periods without overcharging.

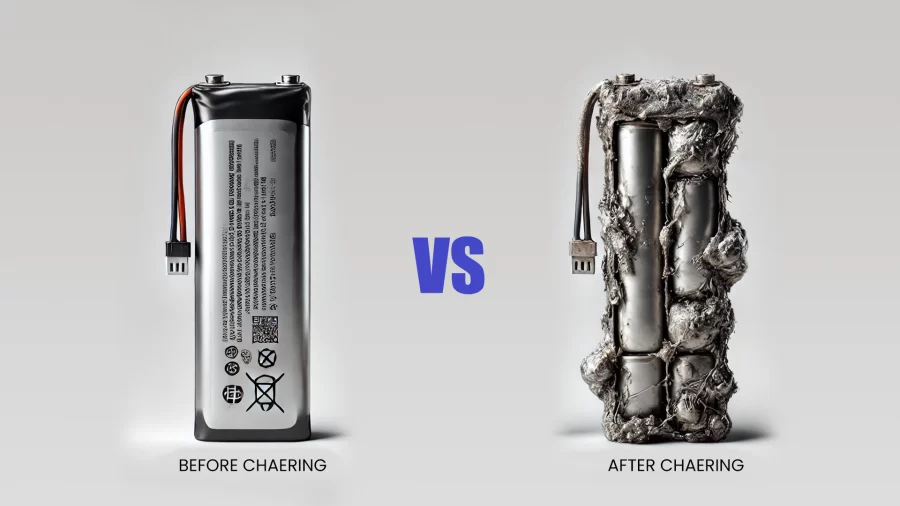

Using a charger mismatched for the battery chemistry can result in overheating, reduced battery life, or even catastrophic failure. Always use chargers designed specifically for the battery chemistry to maximize safety and performance.

Key Risks Of Lithium-ion Battery Pack Charging Process

- Improper charging can lead to severe consequences

- Overcharging lithium batteries may cause lithium metal deposition.

- Abnormal increases in internal pressure and temperature.

- Battery swelling or safety membrane rupture.

Custom Lithium ion Battery Charger Design Principles

Designing high-quality custom chargers requires considering multiple principles to ensure safety, performance, and compatibility. We’ll explore more key principles.

Safety Performance

Safety is the foremost consideration in custom charger design. High-quality chargers should integrate multiple safety protection mechanisms to prevent potential hazards and failures.

The Current Interrupt Device (CID) is a safety device. It automatically turns off the circuit. This happens when it detects high temperature, high voltage, or unusual pressure. It helps prevent battery overheating or explosions.

- Temperature Monitoring

Tracks battery temperature in real time to ensure safety during the charging process.

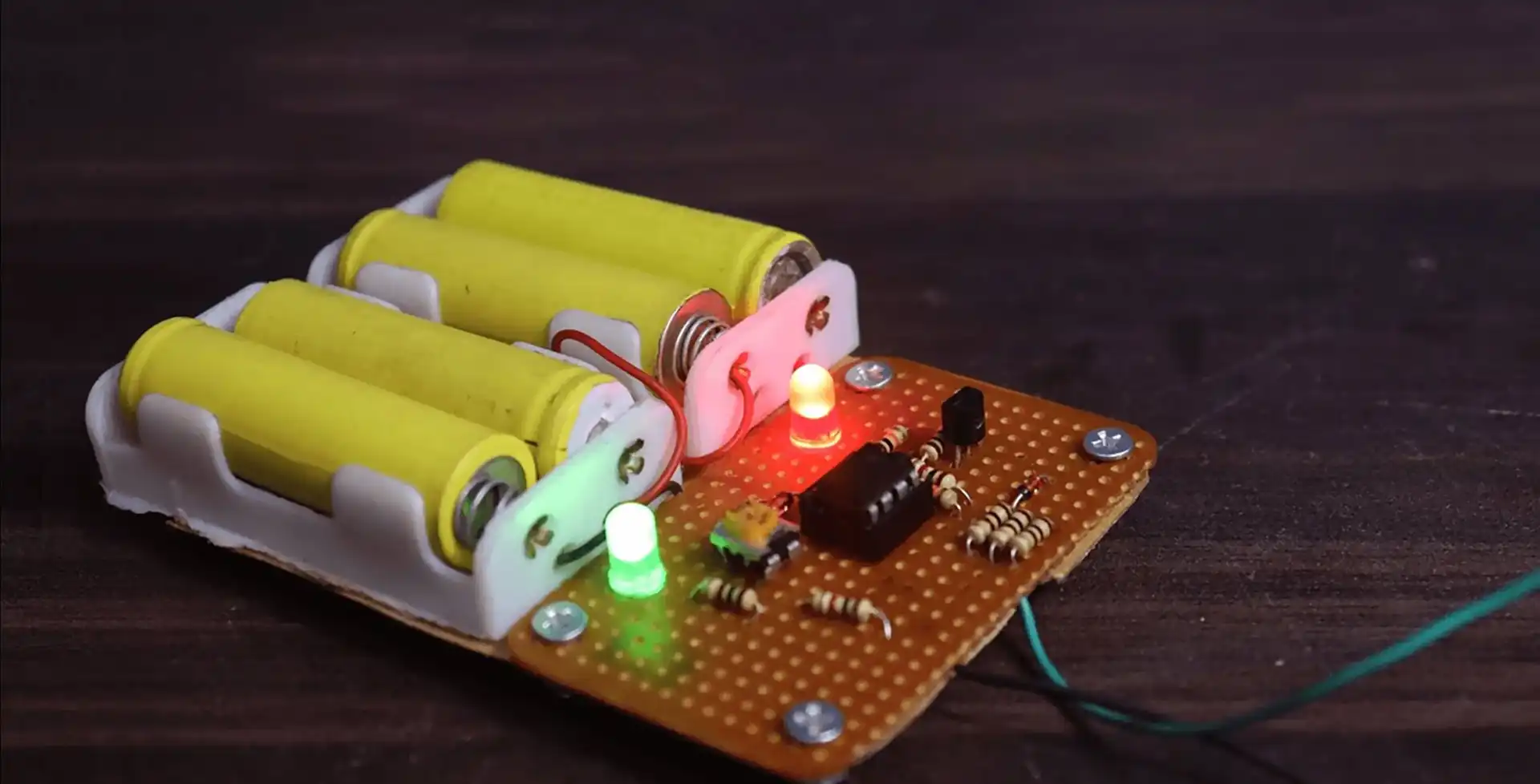

- Overcharge Protection

Precisely controls the charging termination point to prevent damage or failure caused by overcharging.

- Voltage and Current Limitations

Ensures the charger operates within safe ranges to avoid harming the battery.

Performance Optimization Strategies

These strategies are excellent for designing advanced chargers. Here’s a deeper dive into each point to help refine charger performance further:

Customized Charging Algorithms for Different Chemistries

Each battery type (e.g., lithium-ion, lead-acid, NiMH) has unique charging characteristics. Designers should create specific algorithms to optimize the charging process.

Optimized Charging Rate

Adjust charging speed to balance efficiency and battery lifespan. Combine fast charging with safety measures to avoid excessive stress on the battery.

Improved Charging Efficiency

Use advanced technologies like Maximum Power Point Tracking (MPPT) to charge efficiently in different conditions.

Compatibility and Flexibility

Building charger compatibility and flexibility is crucial for diverse applications. Here’s how you can incorporate the suggested features effectively:

Support for Multiple Input Sources

The input of Chargers is available with USB, solar panels, and other sources. This makes them easier to use.

Customize Parameter Settings

Allow users to customize output parameters, such as voltage and current, to suit different battery types.

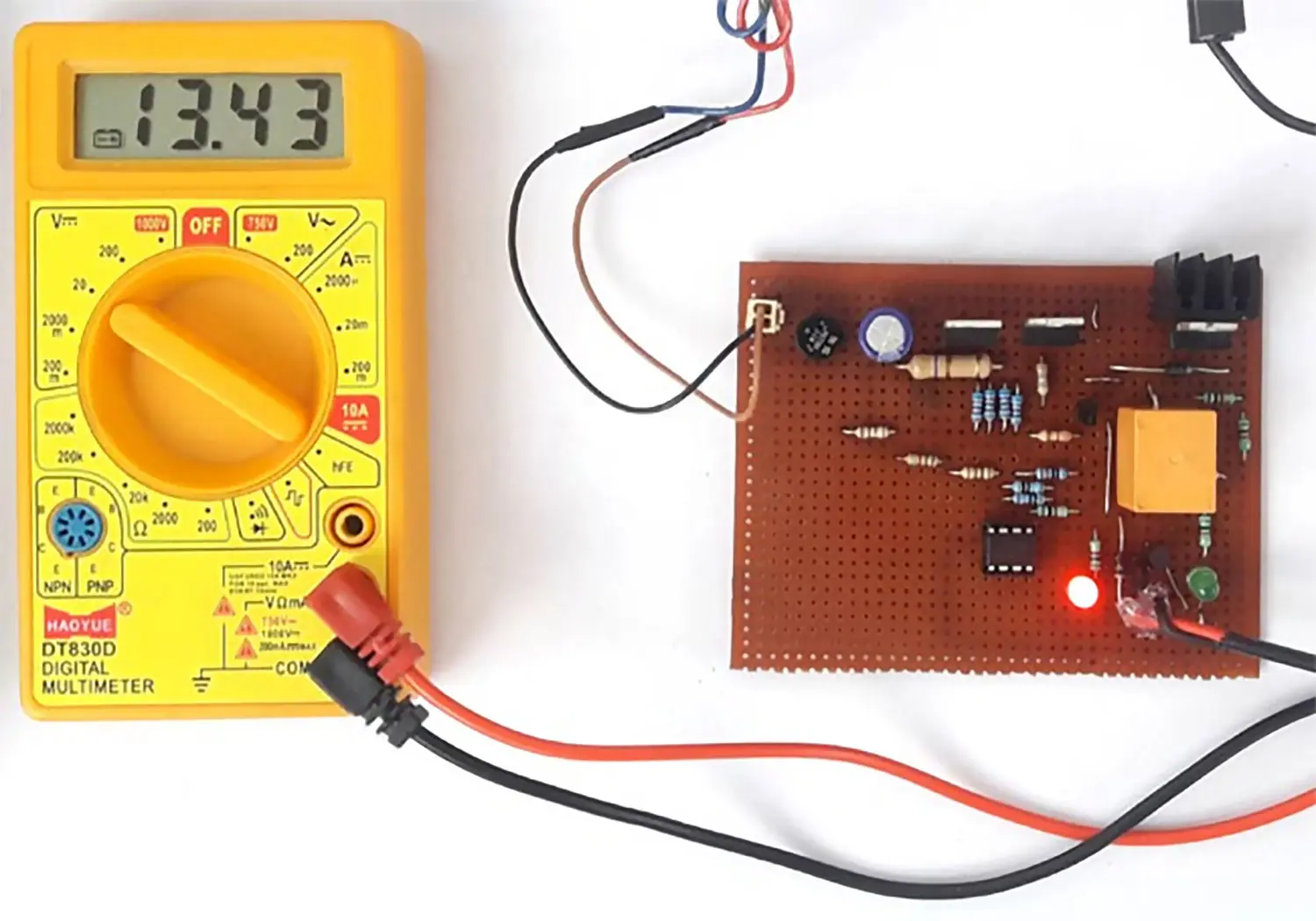

Monitoring and Feedback Mechanisms

Integrating monitoring systems can provide real-time tracking of the charging status and enable timely actions:

Telemetry Systems

Monitor voltage, current, and temperature using interfaces like I2C. This helps ensure a quick response to any problems.

Fault Alarm Function

Automatically alerts and takes corrective measures when thresholds exceed limits.

Environmental Adaptability

Design chargers to perform reliably under various environmental conditions:

Temperature Range

Chargers can operate in extreme temperatures, whether high or low.

Moisture and Dust Resistance

Use appropriate materials and packaging to enhance durability according to usage environments.

CM Batteries’ engineering team always comprehensively considers safety, performance, compatibility, and environmental adaptability to achieve the best product outcomes.

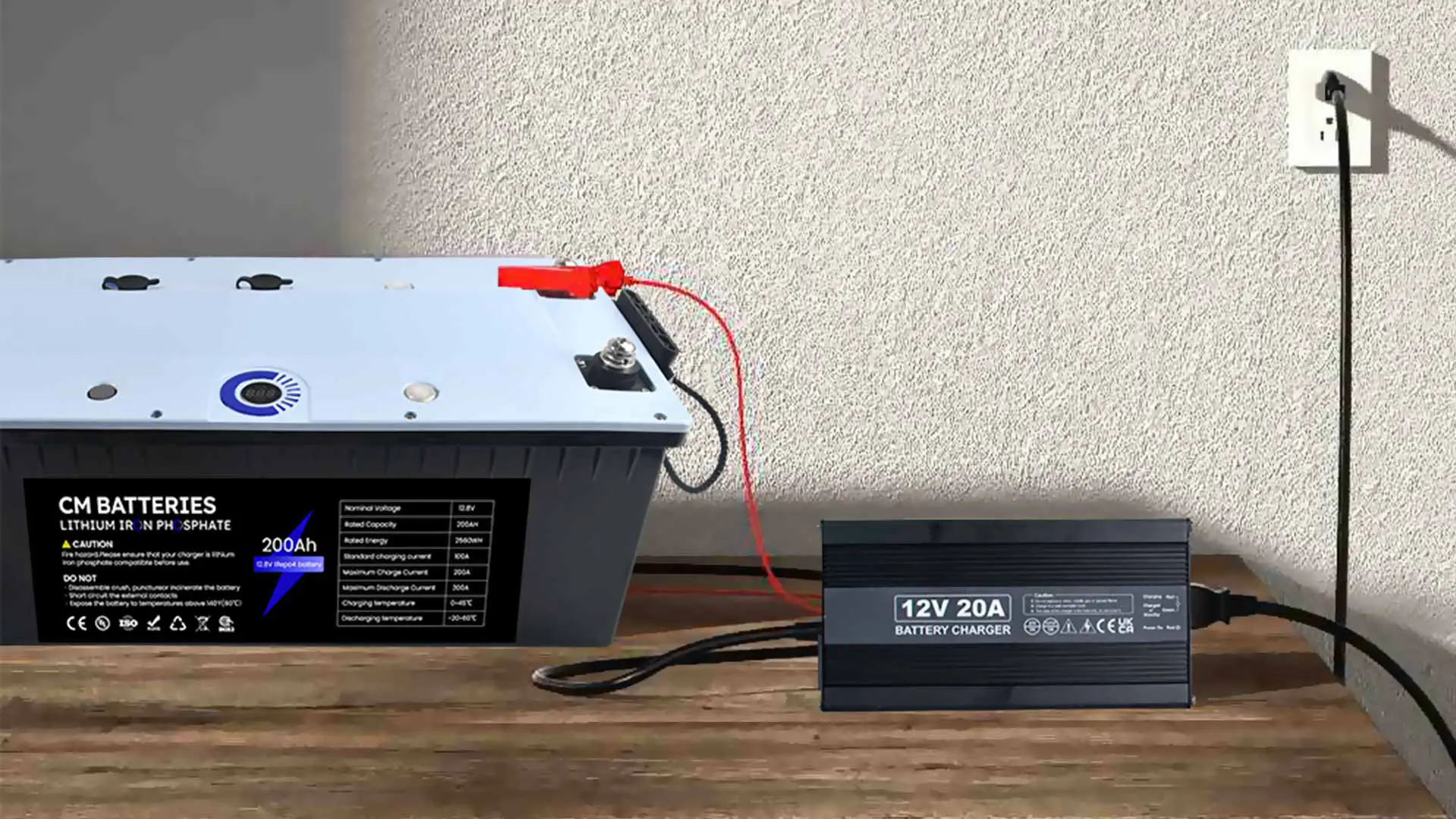

CM Batteries’ Custom Lithium ion Charger Solutions

CMB provides end-to-end custom charger solutions through the following process:

Inquiry and Evaluation

When we get your custom charger inquiry, we will ask you some questions about the battery pack specification, such as the voltages, charging needs, and target markets.

Design and Customization

- Creation of a custom charging profile.

- Design of matching charger hardware.

- Ensuring optimal compatibility and performance.

Safety Integration

- Embedding advanced safety features.

- Preventing overcharging.

- Monitoring temperature and current.

- Implementing fault protection.

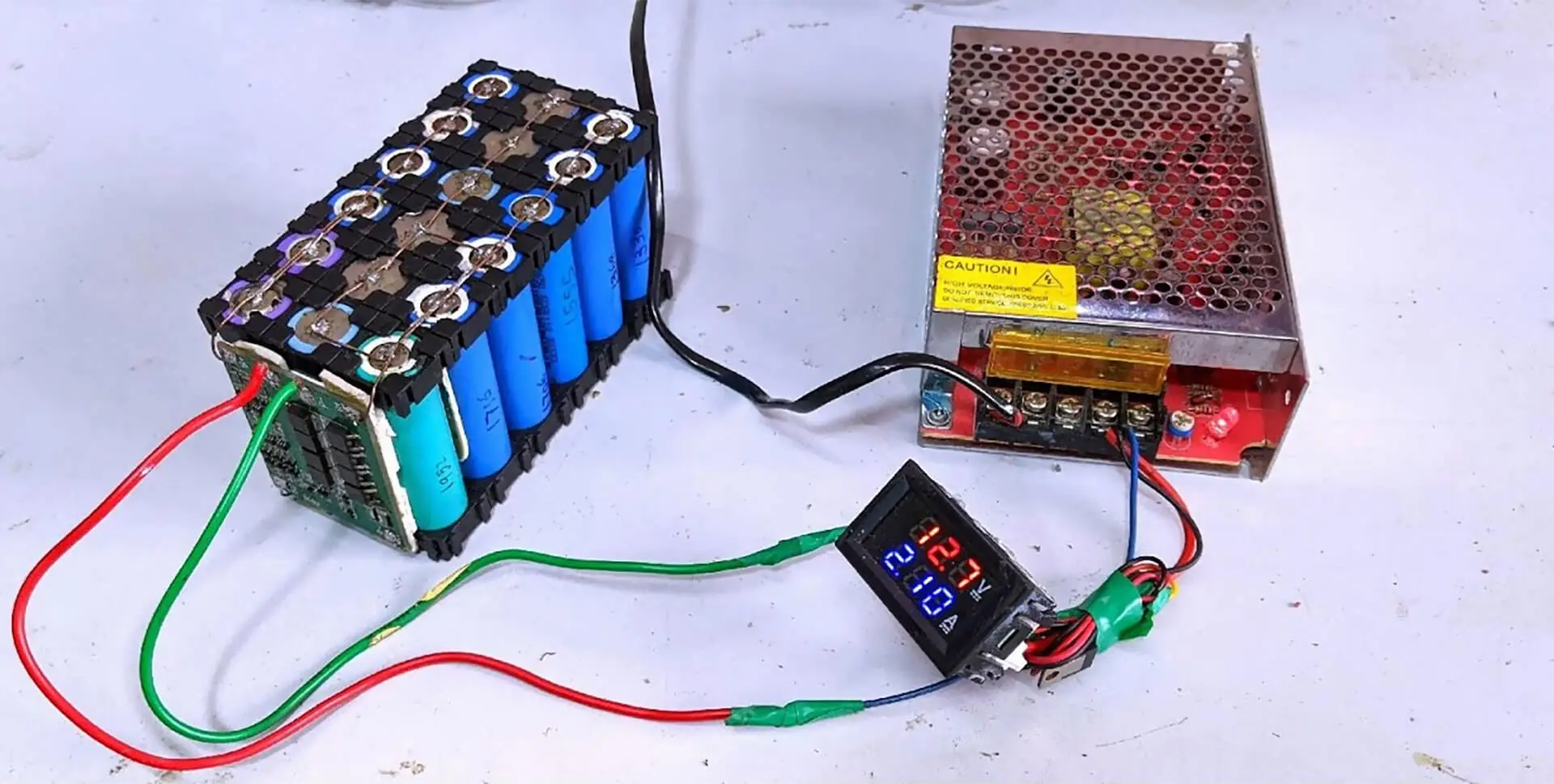

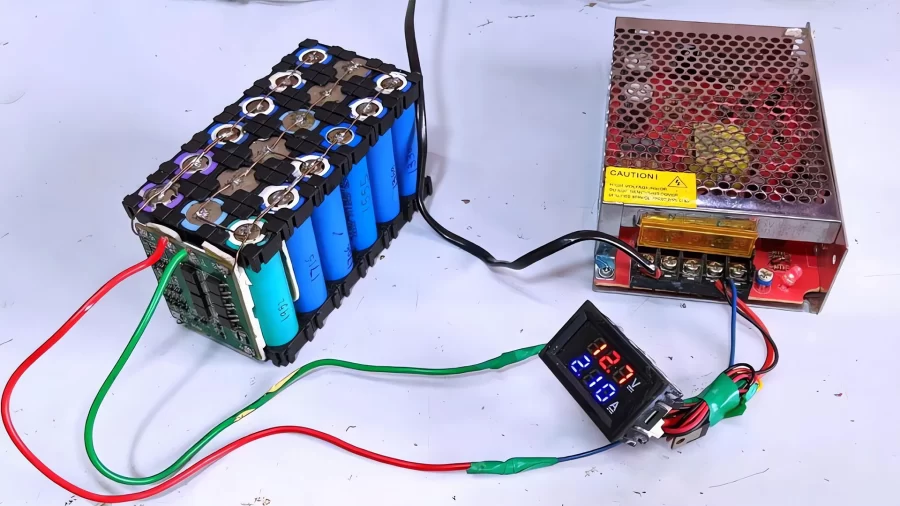

Prototype Development and Testing

- Developing charger prototypes.

- Test the lithium ion battery charger with the corresponding battery pack before the shipment

- Reliability testing under simulated real-use scenarios.

Manufacturing and Quality Control

- Adhering to strict production standards.

- Compliance with UL, and CE certifications.

- Ensuring product durability.

- Implementing precise quality control measures.

Delivery and Long-Term Support

- Providing seamless integration support.

- Offering technical guidance.

- Continuous performance tracking.

- Delivering ongoing optimization services.

Custom chargers are more than just charging devices; they are integral systems designed to ensure the safety and optimal performance of battery packs. Through professional design and precise engineering, these chargers significantly enhance battery efficiency and equipment reliability.

At CM Batteries, we are dedicated to delivering comprehensive, safe, and efficient custom charging solutions. Our advanced designs help clients achieve superior performance and maintain a competitive edge in today’s fast-evolving technological landscape.