In custom battery pack design, engineers face the challenge of balancing high energy density with space constraints, lightweight design, and thermal management. Tabless battery cells, known as full-tab battery cell, uses the entire end of the current collector as the connection point to reduce internal resistance, optimizes heat dissipation while ensuring ultimate safety. This design is a innovation in battery structure and manufacturing that offers faster charging speed and high-rate discharge for high-current devices. This article dives into the principle, advantages, application and market prospects of tabless battery.

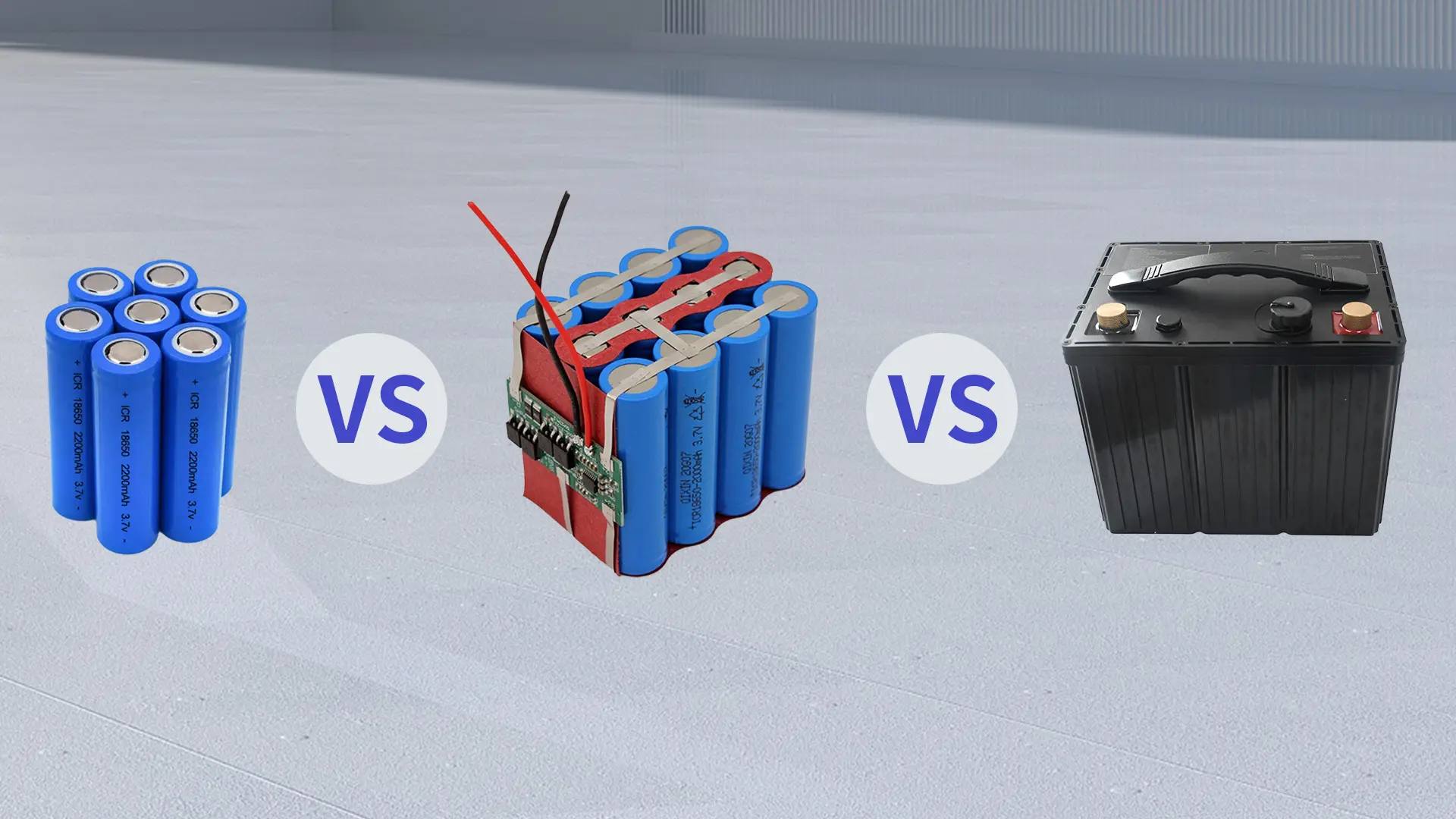

What is the Difference Between Tabbed and Tabless Batteries?

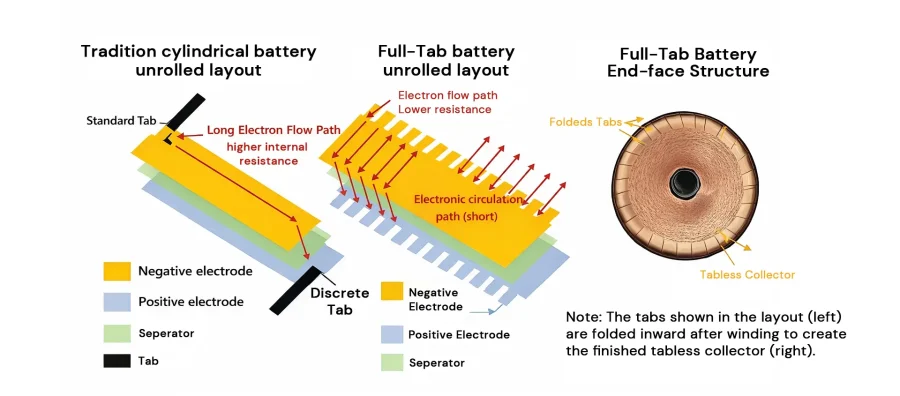

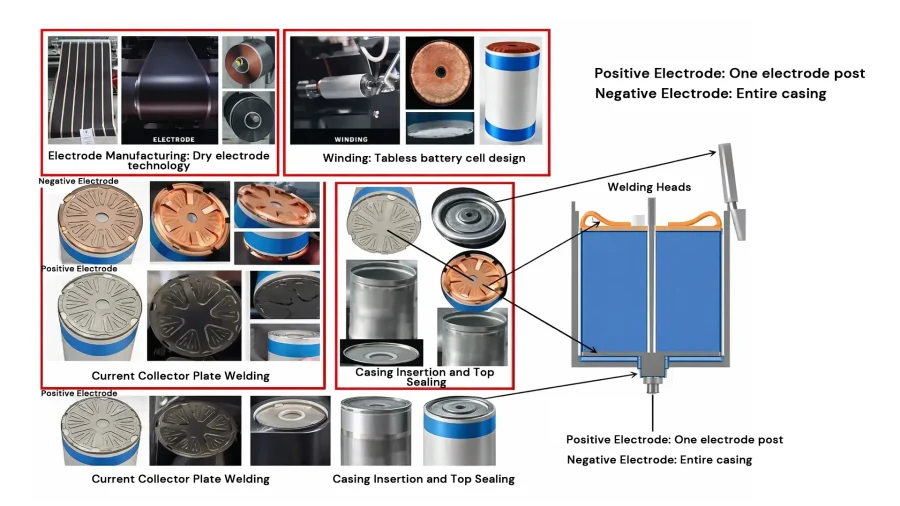

Tabless Battery Cell Design

The Tabless (full-tab) battery cell have full tabs that cutting from positive and negative electrodes. It upgrades the traditional single or double tab line contact to surface contact. Through winding and stacking processes, this design uses the entire perimeter edge of the uncoated tail region of the positive(aluminum) and negative(copper foil) current collectors of as the conductive channel, thus eliminating the tab welding process.

Mechanism: Current flows radially and transversely through the current collector, rather than flowing longitudinally along the entire length of the foil to discrete tab. Reasonable tab positioning shortens current transmission distance within the electrode, ensuring uniform current distribution, reducing internal resistance and improving the battery’s discharge rate capability. What’s more, less materials reduce battery’s weight and volume.

Tabbed Battery Cell Design

A tabbed battery cell only has two tabs, which connect the positive and negative electrodes to the external circuit through welding. This process causes material stress that affects battery stability, such as in traditional 18650 cylindrical batteries.

Mechanism: Traditional tabbed battery cell draw current from the positive and negative electrodes through one or more small and welded metal strips known as discrete tabs. It has simple structure, but results in long electron flow path and high internal resistance for large-format cells.

Tabless VS Tabbed Battery Cells: Key Differences Explained

Thermal Stability and Safety

- Tabless battery enables uniform current conduction across the entire electrode, reduce internal resistance, and minimizes local overheating, exhibiting enhanced thermal stability.

- Tabbed battery generates current conducted through discrete tabs, causing higher electrical resistance. This localized resistance leads to hot spots and increases the thermal runaway risk.

Battery Lifespan

- Tabless batteries eliminate discrete tab welding and reduce stress concentration points, offering structural stability and long cyclelife over charge and discharge cycles.

- Tabbed battery‘s welded tab joints experience material fatigue during repeated cycles, which degrades structural integrity.

Advantages of Tabless Battery Design

Lower Internal Resistance

- Shortened Current Path. Tabless battery design covers the entire surface of the current collector with tabs, reduces electron flow distance and resistance.

- Increased Conductive Area: The full-tab design increases the contact area between the current collector and the battery casing, providing conductive pathways. The resistance formula R=ρL/S, where R is resistance, ρ is resistivity, L is length, and S is the conductive area. Increasing S reduces resistance.

- Reduced Contact Resistance: Laser welding ensure connection between the current collector, the casing and current plate, reducing the contact resistance.

High Energy Density

The tabless battery design reduces the space occupied by the tabs, allowing battery to accommodate more active materials within same volume and weight, thereby increasing energy density. It offers higher energy storage and longer battery life for devices such as drones, robots and power tool requiring lightweight and long runtime.

Great Heat Dissipation

- Reduced Internal Resistance and Heat Generation. The tabless design shortens the current path by using the entire current collector as the tab, reducing the battery’s internal resistance by 70%. According to Joule’s law(P = I²R), this reduction in internal resistance(R) directly reduces ohmic heat generation during charging and discharging.

- Uniform Current Distribution. Full-tab battery structure results in uniform current distribution within the battery, reducing the temperature difference and minimizing the impact of thermal gradients on battery lifespan.

Superior Temperature Performance

- High-Temperature Performance. The tabless battery design reduces internal resistance by increasing tab number and reducing heat generation during high-current charging and discharging. Studies show that full-tab batteries reduces 35% high current discharge temperature.

- Exceptional low temperature performance. Full-tab battery offers low internal resistance, which ensures current conduction and reduces energy loss. Its all-tab design reduces localized heat accumulation.

Production Efficiency and Cost Advantages

- Reduced Manufacturing Costs. Increased output from faster coating speeds and integration of processes like laser cutting and current collector plate welding, which reduces additional tab welding steps and material costs.

- The mass production of tabless batteries helps to further reduce their unit cost.

High Discharge Rate Performance

The tabless battery design covers the entire surface of the current collector, shortening the electron transport path and reducing internal resistance. This enables the battery to support 5C fast charging performance, meeting the demands of high-power devices such as power tools, drones, and electric bikes.

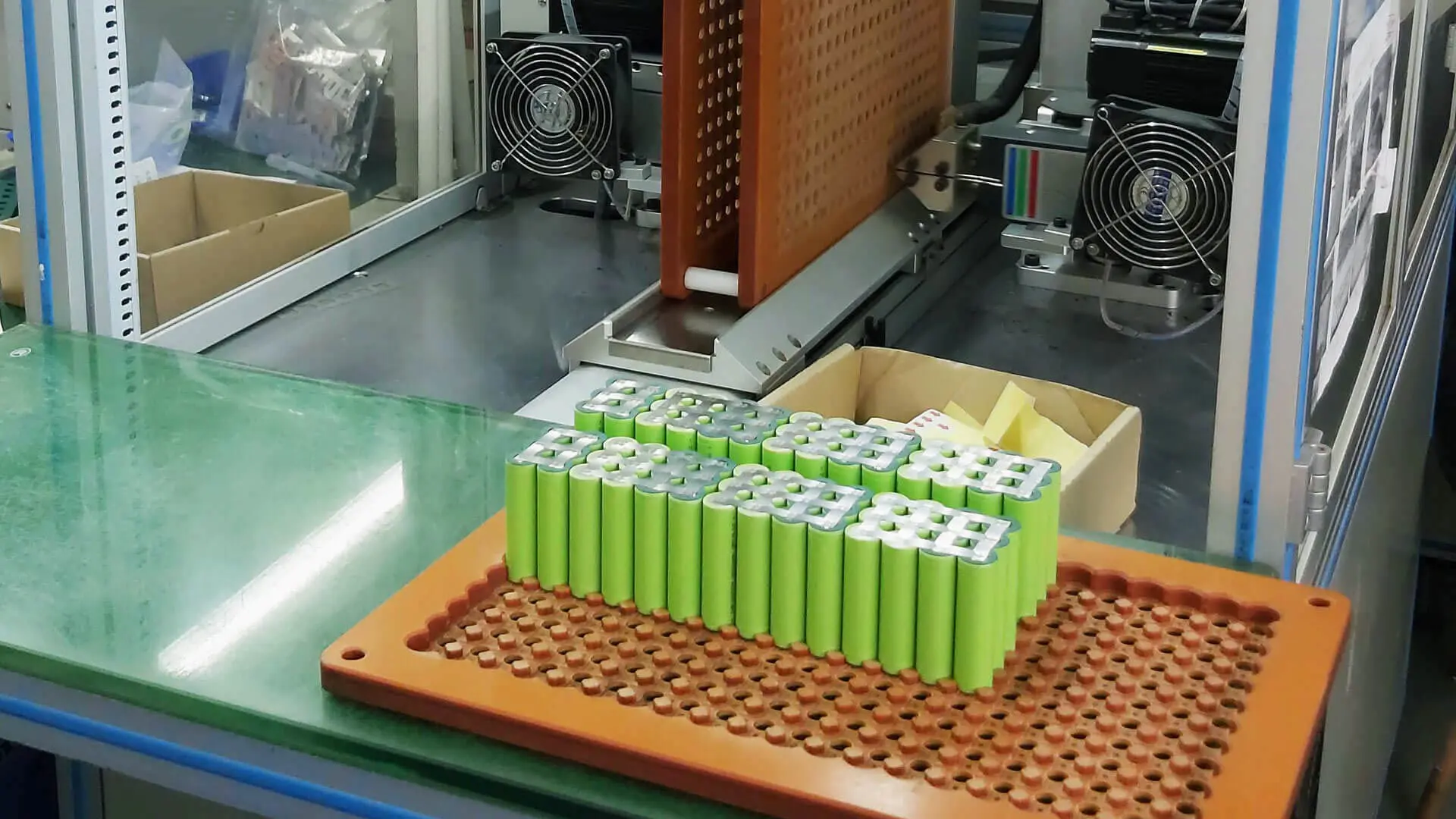

Tabless Battery Cell Production Process

The production of full-tab batteries involves various technologies for improving production efficiency. Optimizing these manufacturing processes enhances production efficiency and reduces costs.

Dry Electrode Technology

Combined with the tabless battery technology, the dry electrode process eliminates steps like coating and drying used in traditional wet processes, improving production efficiency and energy density while reducing production costs.

Pressing Process

This process involves pressing the tabs to make them fit the surface of the current collector, forming the tabless structure. It has low equipment investment and high production efficiency, but face issues with low yield and poor consistency.

Laser Cutting and Folding Process

In this process, the tabs are cut into specific shapes using laser cutting, then folded or wound to connect with the current collector. This method provides high consistency in the products but requires high equipment investment and has lower production efficiency.

Laser Welding Technology

Laser welding is used to connect the tabless design to the current collector plate or battery shell. The high-precision laser welding ensures stable and reliable current transmission through surface welding. This technology requires high control over laser intensity, focal length, and welding parameters, making it a key step in large-scale production of tabless batteries.

Custom Tabless Battery Pack Solutions with CM Batteries

Manufacturing custom tabless battery pack requires a thorough, step-by-step evaluation and professional engineer team to craft tailored battery solution that meets your specific needs. CM Batteries strives to put capability at the first place.

Production Process From Concept to Mass Production

- Definition & Evaluation. At first stage, we evaluate basic specifications, such as power, capacity, voltage, and size, ensuring the battery pack meet tradeoff of weight, volume and energy density.

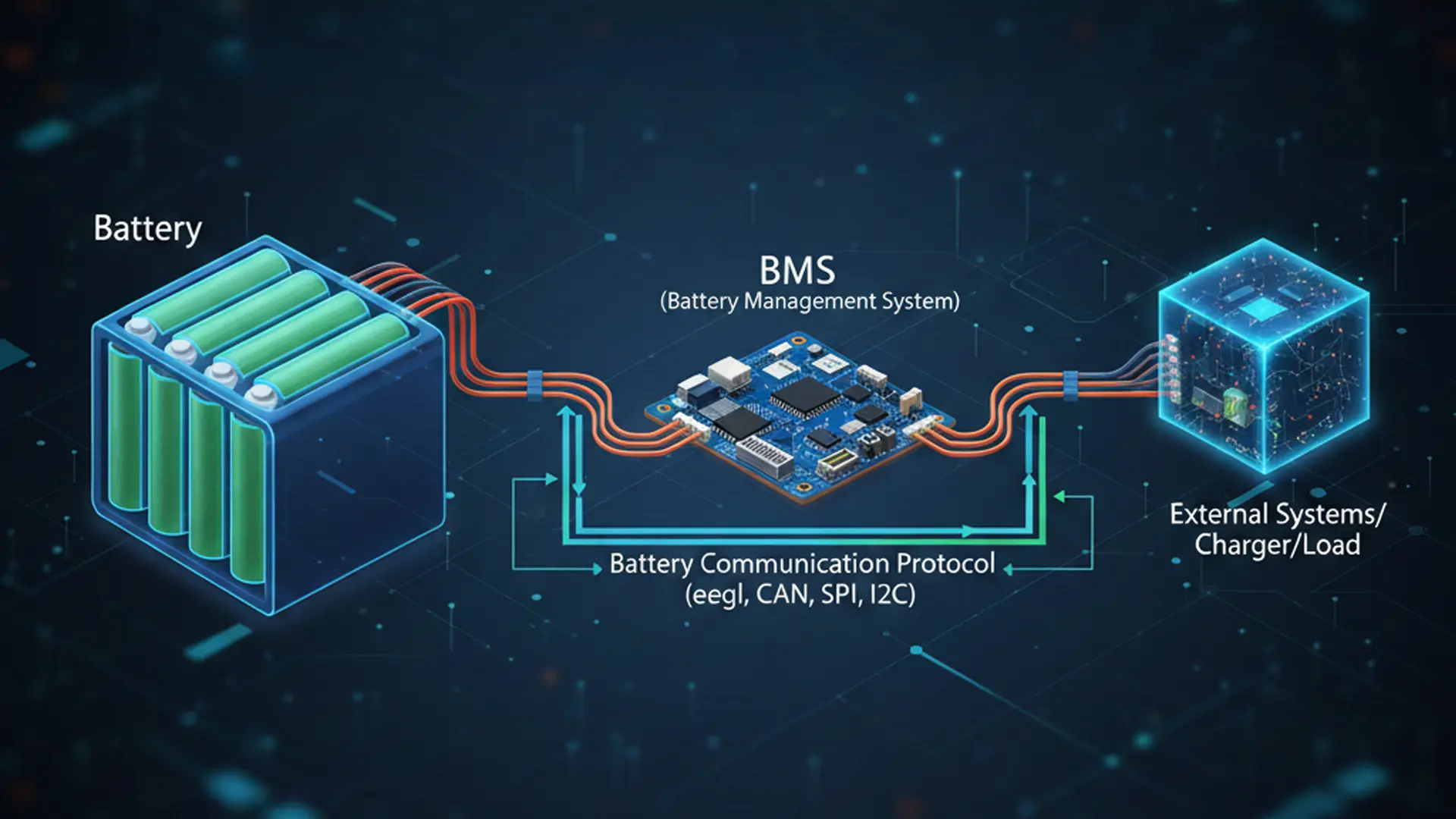

- Design & Development. Our engineers focus on tabless technology and design the battery internal structure, including cell arrangement, connections, thermal management solutions, Battery Management Systems (BMS). Thermal fluid analysis helps optimize the heat dissipation process, ensuring that the battery remains within safe temperature limits during high-load operations.

- Verification & Validation. We perform extensive charge and discharge cycling, thermal testing to verify that battery packs meet the required safety standards.

- Battery Certifications. We assist customers to pass UL certification, CE marking, and RoHS compliance to boost local market competitiveness.

- Battery Production. We utilizes high-precision welding, laser cutting, and assembly techniques to ensure the consistency and quality of custom full-tab battery pack.

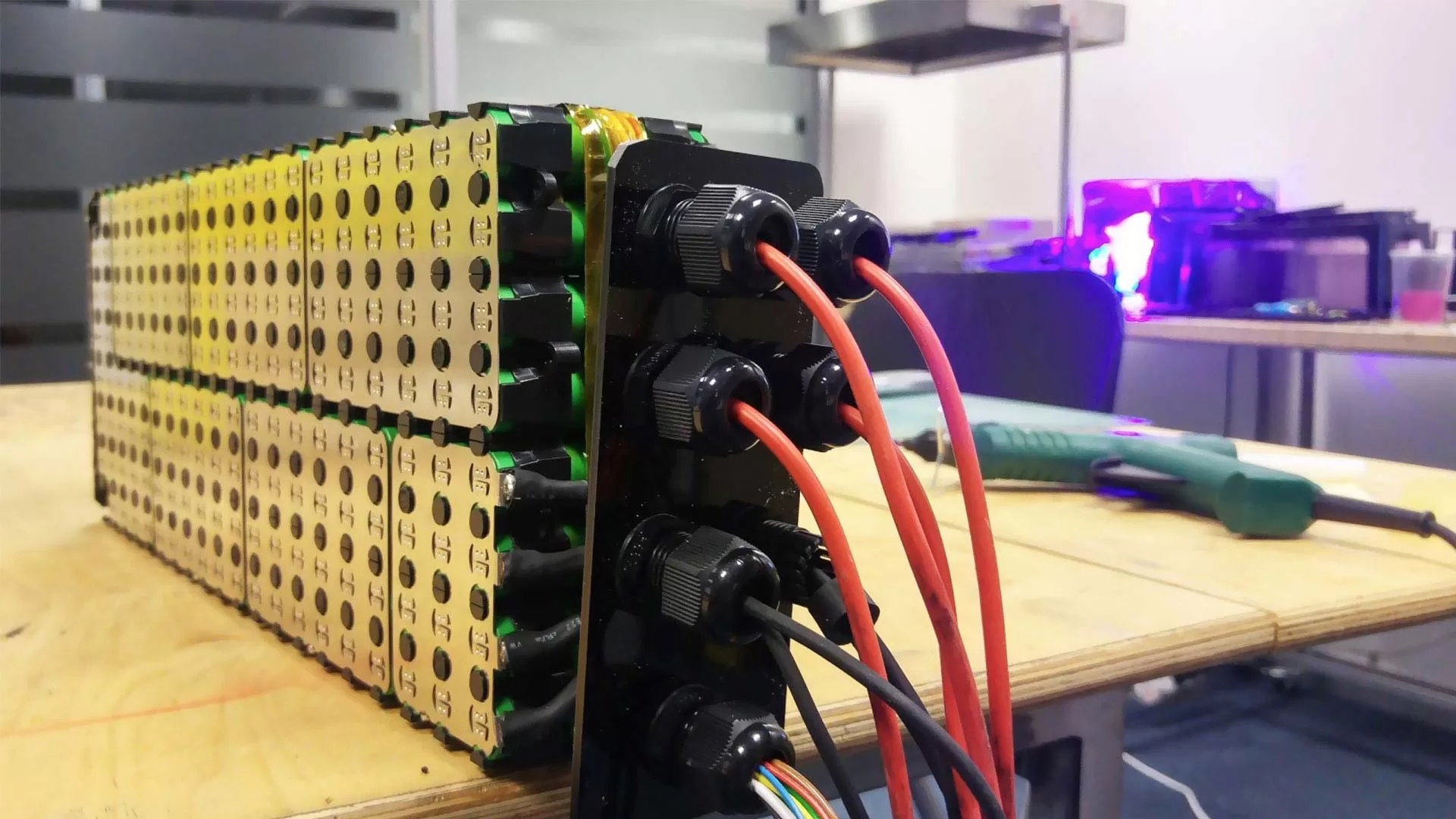

Case Study: High Discharge Full-Tab Lithium Battery Pack for Thruster Motors

A thruster motor manufacturer needed a reliable, high-discharge battery solution capable of powering motors in challenging subsea conditions. We provided Full Tab BAK INR2170-45D cells, which offer high current delivery, superior energy density, and good temperature tolerance. These features contribute to extended runtime and improved stability under demanding environmental conditions.

Customer Request:

- Can the battery offer continuous high-current discharge for thruster motors?

- Will the pack operate reliably in marine environments (high humidity, salt spray, submersion)?

- Does the solution include safety and thermal management to prevent overheating ?

- Is the battery design durable enough for long service life in subsea equipment?

The 25.2V 49.4Ah Full Tab battery pack offer:

Application and Market Prospects of Tabless Battery Cells

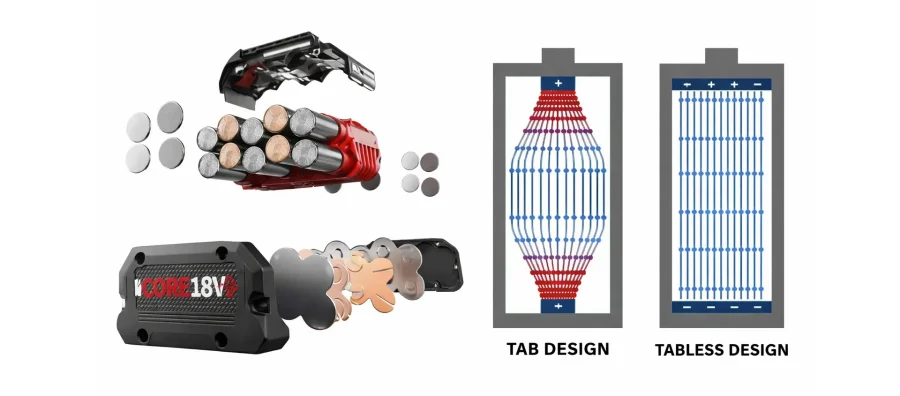

Tabless battery features with low internal resistance and high discharge rate, penetrating fields such as power tools, cleaning appliances, and electric motorcycles. By 2026, the penetration rate of tabless small cylindrical batteries in the power tools sector is expected to reach 38%. For instance, Bosch ProCORE18V+ 8.0Ah power tool benefits from tabless battery technology, featuring numerous parallel current paths to reduce internal resistance and heat generation.

And the tabless cylindrical battery cell market is excepted to grow at the compound annual growth rate (CAGR) of 18.2% from 2025 to 2033.

Full-tab battery are also being used in emerging fields that requires high power due to superior energy density and long cycle life, such as humanoid robots, unmanned aerial vehicles (UAVs), eVTOL and data center BBUs.

Innovative material and process optimization driving down costs and continuous demand from emerging sectors, tabless batteries are poised to become the third major mainstream technology, alongside square and pouch cells. They are set to lead the global transition into the “tabless era” of power batteries. Tabless technology will be a engine for industry upgrades and supports the energy transition, whether by driving the fast-charging revolution in consumer electronics or improving cost efficiency in electric vehicles.

FAQs About Tabless Battery Cells

Which Companies Manufacture Tabless Battery Cells?

Companies like EVE Energy, Changhong Sanjie, and BYD are producing tabless battery cells at 2026 schedule. The tabless battery cell is high-rate cell that offers low internal resistance and high discharge capacity, enabling direct support for high-power output by connecting multiple cells in parallel. CM Batteries manufactures custom tabless battery pack, providing tailored technology solutions based on specific requirement.

What are Differences between Tabless Batteries and Multi-tab Batteries?

Tabless battery design eliminates die-cutting of the current collector, simplifying the manufacturing process. Multi-tab batteries, which increase the current carrying area by placing tabs at multiple points, are more complex and require more die-cutting steps.

Are Full-tab Battery Cells More Efficient than Half-tab Cells?

Yes, full-tab battery cells are efficient than half-tab cells. They reduce internal resistance, increase conductive area, allowing for higher charge and discharge rates with better heat dissipation. This leads to improved performance in high-power and fast-charging applications. What’s more, the tabless design simplifies welding, reducing production costs. In contrast, half-tab cells have higher internal resistance and uneven heat distribution, resulting in lower efficiency and higher costs.

What is an Tabless Battery Design?

Tabless battery design optimizes the current flow path of the current collector and increases the current-carrying area of the tabs. There is no need for coating and die-cutting of the current collector. Instead, the positive and negative electrode of the battery is connected to the tab through ultrasonic welding, thus simplifying the assembly and welding process.