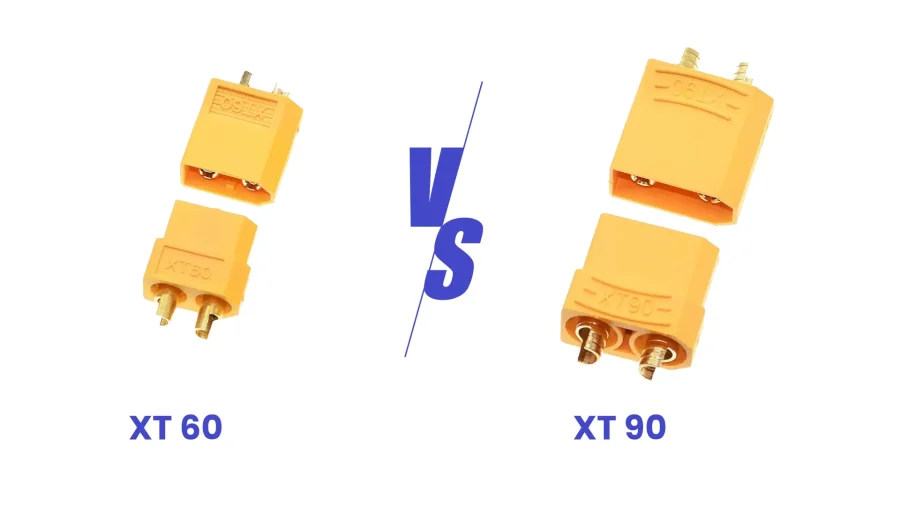

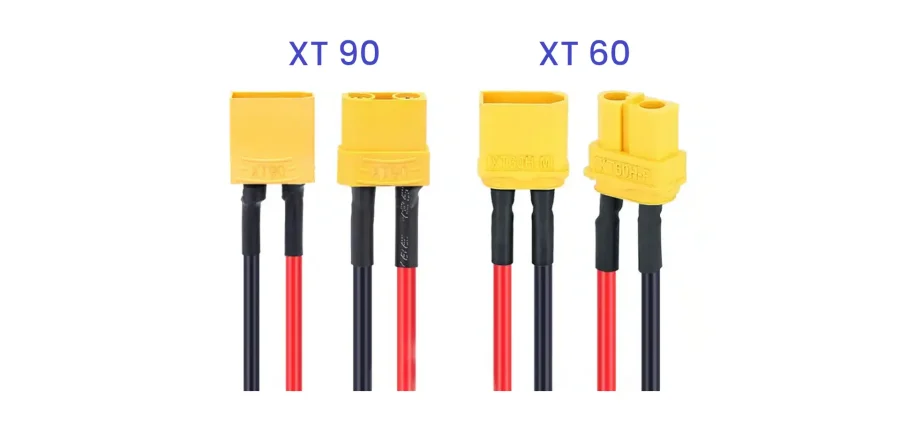

XT connectors are used in drones, RC vehicles, and other high-discharge-rate lithium polymer battery applications. Among them, XT60 and XT90 battery connectors stand out for their high conductivity and durability. The XT60 connector features a compact size and compatibility, making it suitable for size-constrained devices. In contrast, the XT90 connector stands out for its larger design with lower resistance, ideal for high-current devices. How to choose the right connector to unlock the full power of your device? This article explores the differences, costs, and applications between XT90 VS XT60 connectors.

What are XT60 VS XT90 Connectors?

Understanding the features of XT60 and XT90 helps you quickly grasp their distinctions. Let’s explore their size and current handling capacity.

XT60 Connector

XT60 connector has a lightweight and compact size, enabling it to fit space-limited devices. They support stable current and frequent start and stop, and are used in medium power devices such as model airplanes, drones.

- Current Rating: XT60 connector has a continuous current rating of 60 amps and a peak current rating of 120 amps.

- Size&Design: XT60 consists of metal contacts and plastic housing with a 3.5mm diameter and 21.6 × 15.7 × 8.4 mm male connector size.

XT90 Connector

XT90 connector has thicker contacts for dealing with higher current. This design withstands vibration and corrosion in harsh conditions, ideal for high-drain devices.

- Current Rating: XT90 connector features with continuous current rating of 90 amps and a peak current rating of 180 amps.

- Size&Design: XT90 has a larger plug spacing, carrying higher current with a 4.5-5mm diameter and a 30 × 21 × 10 mm male connector size.

XT60 VS XT90 Connectors: What are the differences?

| Features | XT60 | XT90 |

| Weight | light | heavy |

| Diameter | 3.5mm | 4.5-5mm |

| Continuous current | 60 amps | 90 amps |

| Peak current | 120 amps | 180amps |

| Price | affordable | expensive |

| Application | RC, drone, e-bikes | Robot, marine boat, solar power |

Are you curious about which connector fits your battery setup? Let’s explore the differences between XT60 and XT90 in terms of current handling capacity, size, heat dissipation, and price.

Current Handling Capacity

XT90 connector handles a higher continuous current rating of around 90 amps, whereas XT60 connector’s 60 amps. That’s because the XT90 connector has thicker conductive material, a larger contact area, and a robust structural design.

What’s more, the XT90 connector handles higher peak current(up to 180A) than XT60 (up to 120A), withstanding greater transient current shocks and performing well in the device’s startup and acceleration.

Size

XT90 connector is heavier and larger than the XT60 because it requires both more robust metal material to ensure safe current transmission, and a larger housing to accommodate larger metal pins and provide better heat dissipation.

XT60 connector has a lightweight and compact size because its less materials and lower current handling needs.

Heat Dissipation Capacity

XT60 connector has a lower heat dissipation capacity compared with the XT90 because it carries a lower current. XT60 heats up rapidly when meeting high current; thus, avoiding overloading ensures safe operation.

XT90 has a larger housing and metal contact parts, which improve heat dissipation and ensure stable operation under high current conditions.

Price

XT60 connector is cheaper than the XT90 connector due to fewer metal and plastic materials and a simpler manufacturing process.

XT90 connector is more expensive because it requires more materials to achieve high temperature resistance and insulation performance. Limited market demand and production scale of the XT90 connector also result in higher costs.

Advantages and Disadvantages of XT60 VS XT90

Advantages of XT60 Battery Connector

- Compact design: XT60 connector has a lightweight size, making it ideal for weight-sensitive applications like drones.

- Cost-effectiveness: The XT60 connector is affordable for the broad market demand, large production scale, and reduced materials usage.

- Versatility: They are suitable for a wide range of applications, such as small battery packs, electric scooters, and portable electronics.

Disadvantages of XT60 Battery Connector

- Limited current capacity. A single XT60 connector carries a limited current and is not suitable for high-power devices.

- Require parallel for heavy-duty setups: Need to connect multiple XT60 connectors in parallel for handling high-load devices.

- No anti-spark design: The Standard version of the XT60 connector has no anti-spark design, so sparks may occur during connection and disconnection.

- Less durability. XT60 is made of fewer materials, is less durable compared with XT90, and is not ideal for power-hungry devices.

Advantages of XT90 Battery Connector

- Higher current-carrying capacity: XT90 supports 90A continuous current, well-suited for devices requiring high current, such as heavy machinery and special vehicles.

- Larger Size and enhanced stability: Its larger size provides more secure insertion and removal, and offers enhanced vibration resistance.

- Industrial-Grade Design: Commonly used in industrial equipment such as photovoltaic inverters and high-power distribution boards.

Disadvantages of XT90 Battery Connector

- Large Size: XT90 connectors are bulkier and heavier, making them unsuitable for compact equipment.

- Higher Cost: XT90 connector is more expensive than XT60 due to more raw material consumption, complex manufacturing, and higher durability.

- Limited Compatibility: Not all devices support the XT90 connector; you need to use an adapter when connecting to the XT60 system.

XT60 VS XT90: Which Connector for Your Application?

XT60:

- Remote Control (RC) and Drones: XT60 connectors are popular in drones, offering a lightweight design with sufficient power capacity for UAVs.

- Power Tools: XT60 connectors are used in electric drills and lawn mowers, providing a compact and stable connection.

- E-Bikes: XT60 connectors are used in lightweight e-bikes, where current demand is lower and a compact design is preferred.

XT90:

- Robotics: For industrial robots and service robots requiring robust power delivery, the XT90 connector ensures reliable current handling.

- Electric Marine Vessels: The Waterproof XT90 connector is suitable for providing electric yachts with a secure and efficient power connection.

- Solar energy system: Use an XT90 connector to connect solar panels and batteries. For high-power solar energy systems requiring large current handling, XT90 is the ideal choice.

How to Choose Between XT60 and XT90?

In a nutshell, choosing XT60 and XT90 depends on your current demand for specific devices. The XT60 battery connector is perfect for devices needing medium power with limited space, such as drones, RCs, and power tools, handling 30A-60A currents with an affordable budget. While the XT90 battery connector is right for high-drain devices, such as robots, marine electric boats, handling 60A-90A currents, and offering higher current-carrying capacity and stability.

Selecting the right connector is the first step, while safety and design of the battery pack are critical concerns. CM Batteries, as a professional lithium battery pack manufacturer, not only provides customized battery packs with XT60 and XT90 connectors, but also offers tailored waterproof, explosion-proof, and corrosion-resistant designs to ensure stable and reliable performance in complex conditions. If you have any requirements, please contact us.

FAQs about XT90 VS XT60

Is XT60 compatible with XT90?

No, XT60 and XT90 connectors are not compatible for different connector sizes and current ratings. However, the XT60 female to XT90 male adapter allows interoperability between the battery and the load device, but increases contact resistance.

How many amps can XT60 and XT90 handle?

XT60 connector carries about 30A–60A continuous current, making it suitable for small drones and remote-controlled cars, while the XT90 plug stably handles 60A–90A, making it suitable for robot battery packs and marine propulsion.

How to Choose Between XT60 and XT90 Connectors?

It depends on your device (ESC) and the battery’s continuous discharge current (C rating). If your system’s peak current frequently exceeds 60A, choose the XT90 for safety and performance. If unsure, the XT60 is sufficient for devices needing low power.

The XT90 is harder to plug and unplug than the XT60. Is it normal due to its tighter fit?

It’s normal. The XT90 has larger metal pins and a stronger shell, and in order to ensure good contact when high current passes through, without loosening or high temperature. Thus, its insertion and removal force (friction) is designed to be greater than that of the XT60.

Is XT90 Superior to XT60?

For high-power systems, the XT90 is better because it more safely handles high currents, reduces heat and voltage drop, and reduces the risk of connector melting.

For low-power systems, the XT60 performs well because it is smaller, lighter, and less expensive, making it adequate while saving space and weight.

Can XT60 Be Replaced with XT90?

Yes, but both the battery and the device must be replaced simultaneously! It is strictly forbidden to make a conversion cable with an XT60 on one end and an XT90 on the other! Mixing different specifications is dangerous, leading to overheating, melting, and short-circuiting.