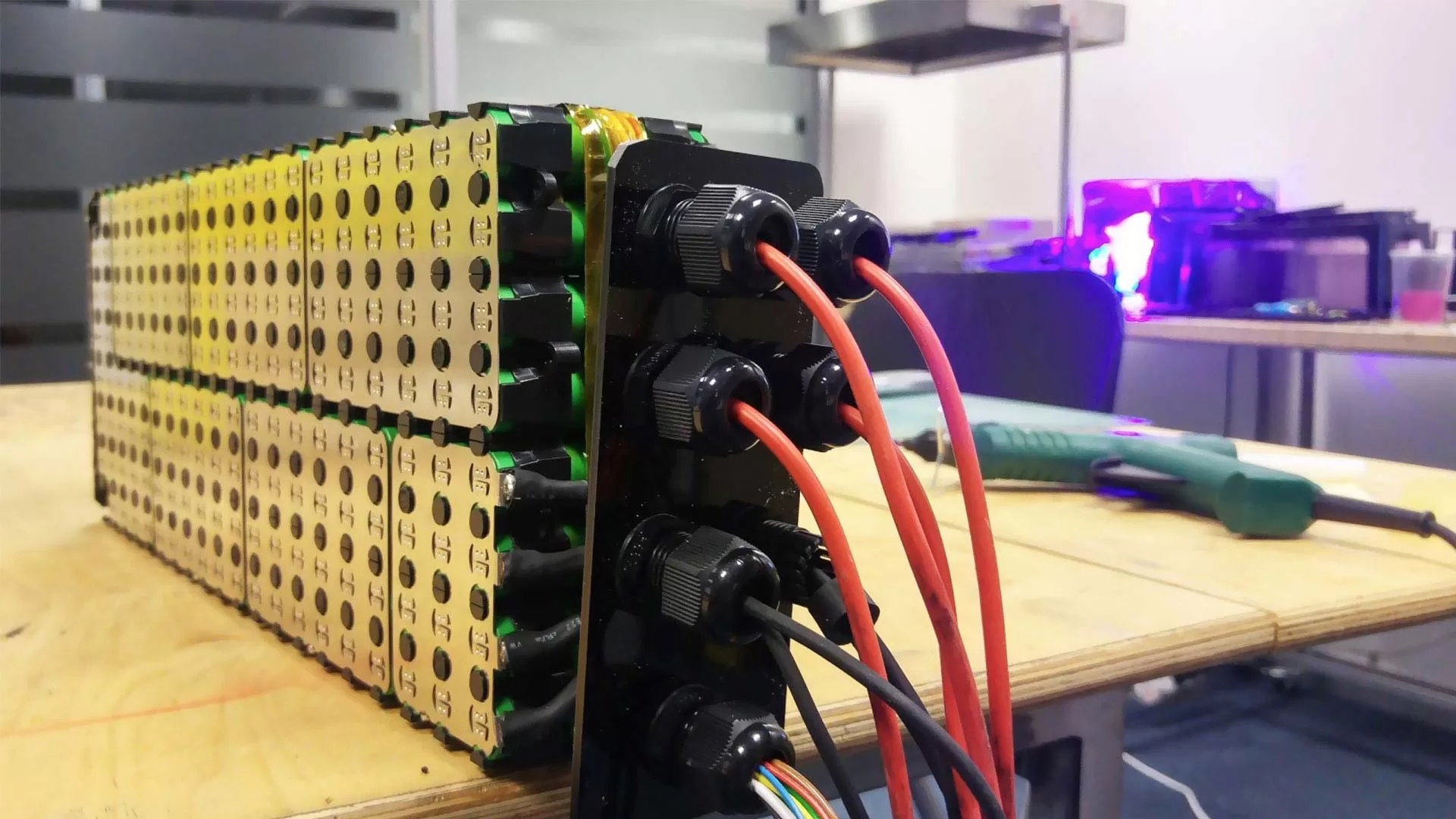

When assembling a lithium battery pack, battery connectors play a key role in electrical performance, mechanical dependability, and system safety. The wrong connector choice can cause to voltage drop, overheating, unstable connections, or even pack failure in high-current applications.

Different battery pack applications, such as industrial chargers, medical equipment, robots, and energy storage systems, necessitate connectors with appropriate current ratings, environmental protection levels, vibration resistance, and compliance requirements.

This guide explains the main lithium battery connector types, how to select the right connector, and design considerations for reliable battery pack integration.

Main Battery Connector Types (By Function & Structure)

Power Battery Connector Types

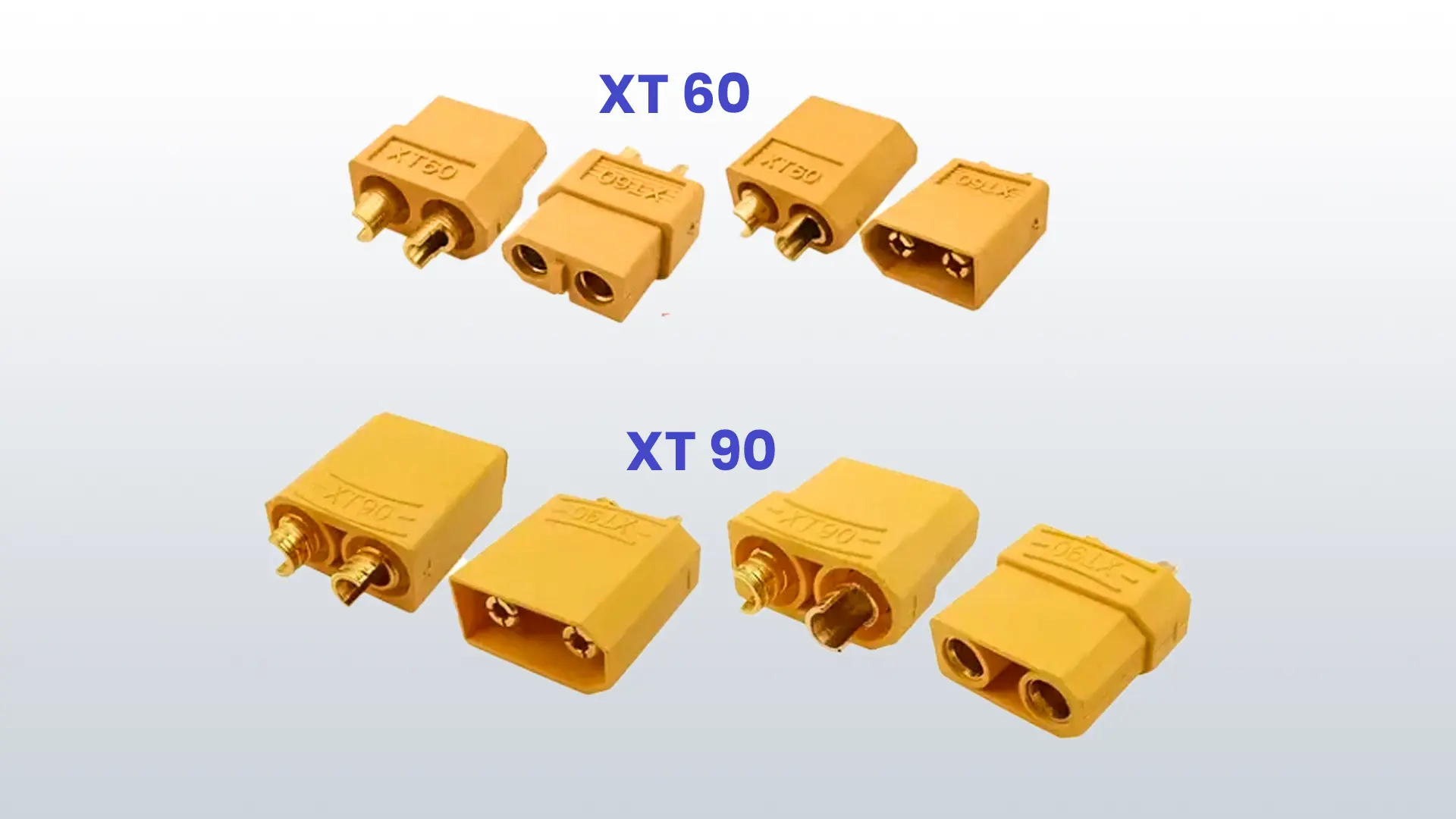

Power battery connectors are designed for high current and voltage transmission, such as power transfer between batteries and devices, and features higher load capacity and lower contact resistance. Their technology involves temperature rise, insertion and extraction cycles, condensation and electromagnetic interference protection ratings, vibration and shock resistance. Industrial machinery, energy storage system and robot battery pack adopt these connectors to ensure high current transfer and safety. XT series (XT30, XT60, XT90) and Anderson Powerpole are common high-current lithium battery connector types.

- XT60 and XT90 are common high-current battery connectors with low contact resistance and heat-resistant housings. XT60 connector handles a rated current of 60A, ideal for drones and electric model planes, while XT90 connector supports up to 90A, powering high-demand devices like electric scooters.

- Anderson Powerpole connectors have red and black color-coded and anti-reverse insertion structure. It supports single-pole and multi-pole modular assembly to meet diverse current rating from low current to high current(such as 45A, 75A, 120A,180A) in underwater robotic vehicle. They feature same-color mating design, where plugs and sockets of the same color can be mated without distinguishing between male and female polarity. It simplifies installation and reduces incorrect connection risk.

Low Current and Voltage Battery Connector Types

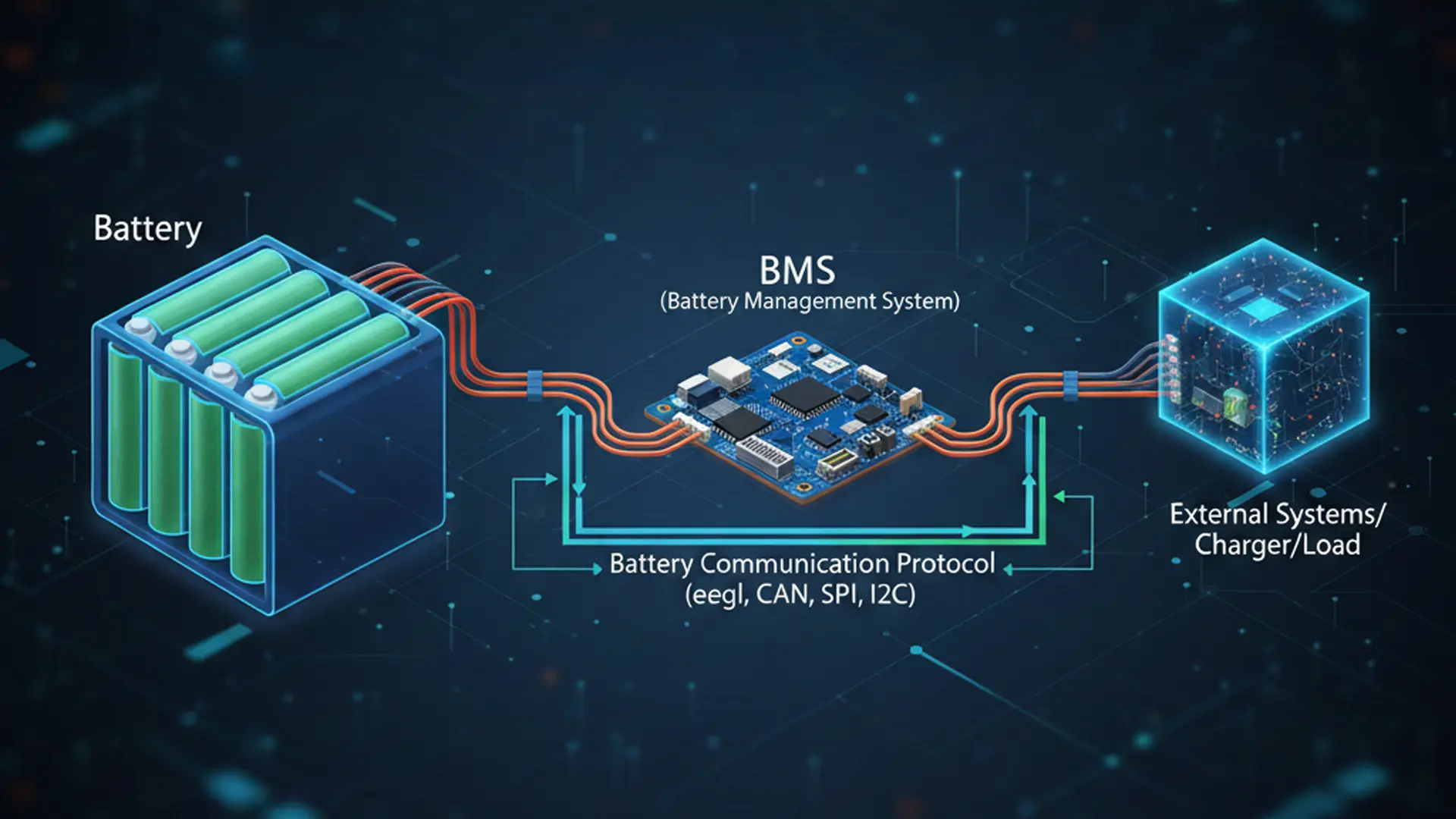

The low current connectors types are designed for low-current data transmission, balanced charging, and BMS monitoring. They are used in battery management systems (BMS) for data acquisition and battery status monitoring, ensuring efficient signal transfer and battery health.

- JST connector features compact rectangular interface and easy plug-and-play functionality with multiple series to support different current requirements, including the XH series (1.5A), EH series (3A), and VH series (up to 10A). It is used in LiPo battery packs for lightweight and compact power sources, such as GPS trackers, Aircraft and drones.

- PH 2.0 and Molex Picoblade connectors shine in limited space and low-current transmission for connecting lithium-ion battery packs in remote-controlled toys. PH 2.0 connector offers low current(1A to 3A) carrying capability while Molex Picoblade connector boasts its high-density design.

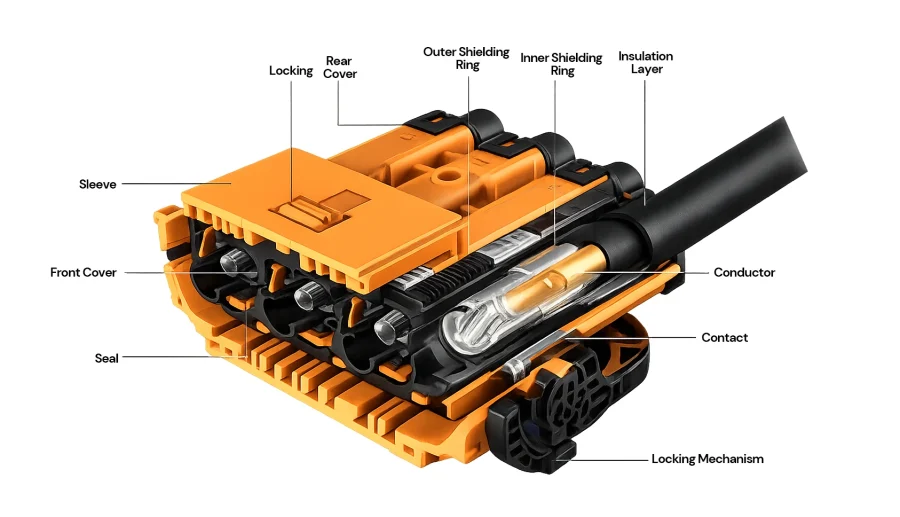

Quick Disconnection Connector Types

Quick-disconnect battery connectors are designed for fast and reliable connection of circuits between batteries and equipment, such as industrial equipment and . They feature plug-and-play designs, floating compensation, and durable materials like stainless steel. These connectors provide safety features such as overcurrent, short circuit protection, and waterproofing (IP67), supporting monitoring and fault diagnosis function.

- EC series(EC2,EC3,EC5) battery connectors feature bullet-style design, cost-effectiveness and easy to install and to handle high current and frequent plugging and unplugging for energy storage, power tool. EC2 supports 20A, EC3 handles continuous 30A with a peak of 50A, EC5 offers continuous 65A with a peak of 100A. They consist of a plug and socket, made from copper alloy and treated with silver or nickel plating to reduce contact resistance, improve conductivity and corrosion resistance.

- Deans T-plug(T-type) connectors outshines with compact T-shaped design, spring contact structure and offer quick insertion and removal. It enables multi-directional connections and perfect for complex wiring in model airplanes and portable electronic devices. Their different series supports rated currents from 10A to 15A, suitable for electric motorcycle.

Terminal-Based Connectors (Ring,Post, Lug, Splice, Clamp)

Battery terminal connectors connect battery with external wires and devices using fastening methods such as bolts, nuts, and clamps. They are responsible for secure connection and efficient electrical current transmission. Standardized battery terminal design facilitates quick installation and removal of batteries and simplifies maintenance. Understanding terminal connector types reduces the failure rate, enhancing efficiency in high current and load conditions.

- Ring terminal connector provides secure connection with closed circular shape for grounding connections and fixed connection points. It is made from copper and copper alloys with tin and silver plating on the surface to improve conductivity and corrosion resistance.

- Post terminal connector is cylindrical metal conductor and used for connecting the positive and negative terminals of batteries. Its one end used for crimping or soldering wires, and the other end connecting to battery terminal through threads and snap-on mechanism.

- Splice terminal connectors joint over two wires together with crimp-on, twist-on, and heat-shrink version. They maintain connections with chargers and loads for power transmission.

- Clamp terminal connector consists of two or more clips, which use spring or lever mechanism to clamp and release. They directly at the battery posts with simple installment and robust structure. Their main body are made from conductive metals such as copper, brass, and phosphor bronze to ensure smooth current flow. Some terminals surface include tin plating and silver plating to enhance corrosion resistance.

Industry Application of Battery Connector Types

Medical Equipment

Medical equipment battery connector types must meet the requirements of high strength and long-term reliability. XT90 connector supports up to 45A (below 85°C) rated current for high-power medical components under heavy loads. It is made of gold-plated brass and PA engineering plastic, ensures stable electrical connections with low contact resistance (≤1.0MΩ) and high insulation resistance (≥2000MΩ), reducing signal loss and interference for accurate medical equipment.

Safety is the cornerstone for medical device battery connectors. Battery connectors meet IEC61984 and GBT34989 standards for continuous usage. And battery connectors materials must comply with CE and RoHS environmental standards and be free of harmful substances.

Marine Application

Battery connector types used in marine applications must withstand challenges like corrosion, high humidity, long-term saltwater exposure, and extreme low temperatures, such as underwater robots (ROVs) and offshore oil platforms. Ring terminal and flag terminal are used in marine environment thanks to tight design and great stability.

EC5 battery connector features standard interface with IP68 protection rating, supporting power and data transmission, and control signals. Its housing is made of corrosion-resistant materials, such as stainless steel and engineering plastics and treated with nickel or chrome plating.

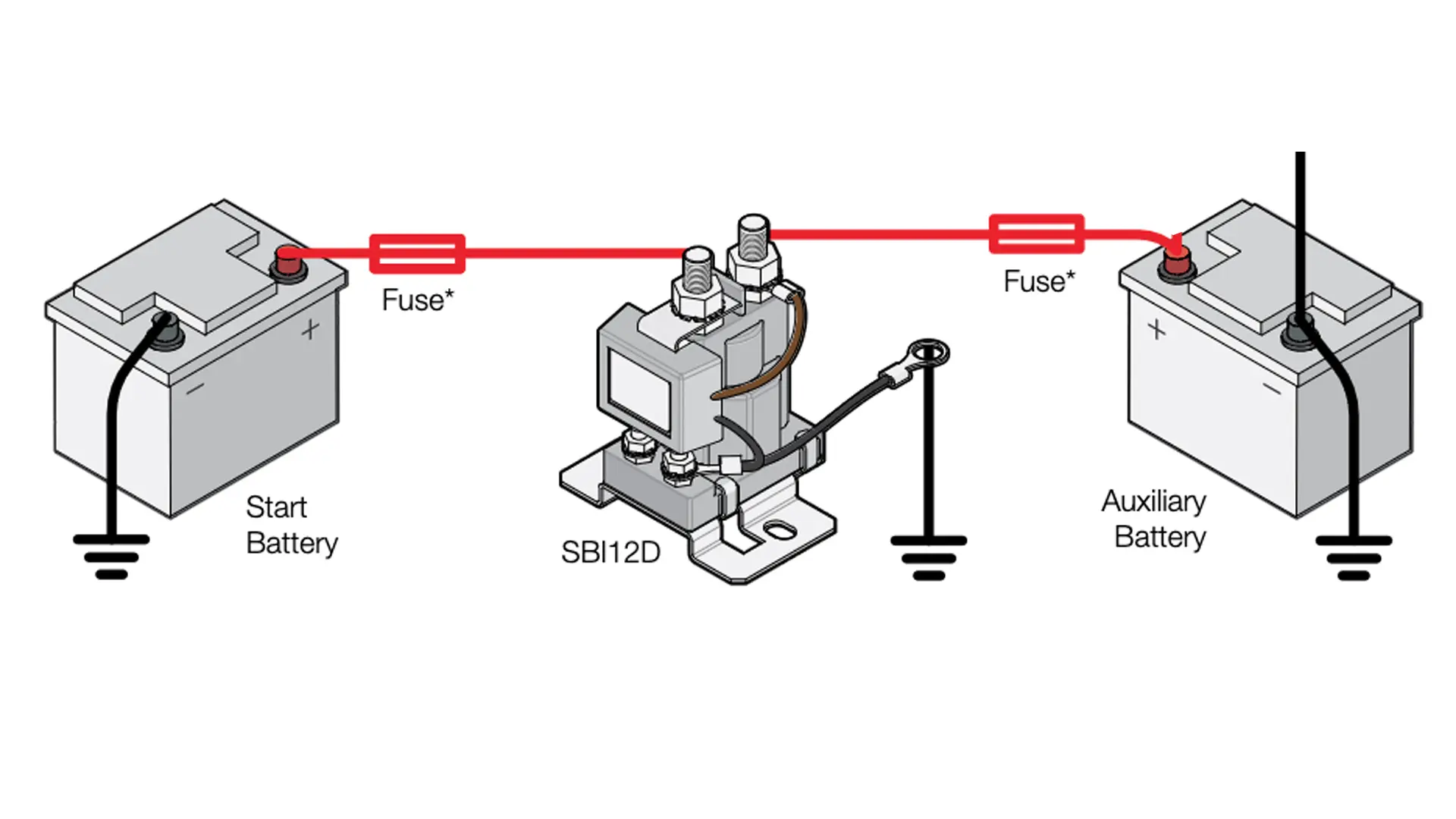

Industrial and Energy Storage Applications

Battery connector type is essential in industrial equipment, requiring ability to withstand high voltages and large currents in environments with vibration and extreme temperatures. Battery connectors for energy storage equipment connect battery modules, battery packs to power transmission and signal transmission. IEC62619 highlight the critical safety and performance demand for ensuring reliable connections within battery systems

Anderson battery connectors specializes in high-power connectors designed for heavy-duty applications. Their SB series connectors are popular for their high current capacity and secure locking mechanism, ideal for connecting large battery packs in electric vehicle motors and industrial machinery.

Key Considerations for Selecting Battery Connector Types

Current,Voltage and Material Selection

- Current Carrying Capacity. Battery connector’s continuous current carrying capacity must be greater than the maximum current of the battery system for avoiding over-current. XT series and Anderson are typical high-current battery connectors while

- Voltage Rating. Selecting battery connector matches the voltage platform of the battery system to ensure power stability and avoids electrical arcing. JST connector and are preferred for low voltage system. For instance, 800V high-voltage platform requires battery connector with ≥1000V rated voltage to avoid creepage risks.

- Material Selection. Select highly conductive battery connector materials, like pure copper and copper alloys, to reduce resistance and improve current transmission efficiency. Adopt insulating material of the battery connector with great insulation properties and mechanical strength to extend lifespan of battery system.

Temperature and Moitsure

- Protection Rating: Select battery connector types with appropriate protection rating based on the operating environment, such as IP67 or IP69K, to ensure the connector has good dustproof, waterproof, and oil-resistant capabilities.

- Temperature Range: Battery terminal connector should operate stably within the operating temperature range of the battery system from -40℃ to 85℃ to avoid material degradation or poor contact.

- Corrosion Resistance. Battery connector’s use plating or corrosion-resistant materials in housing and contacts for corrosion resistance in humid, salt spray, corrosive environments.

International Compliance

- International Safety Certification. Choose battery connector types that have passed UL, TUV, IEC international and Electromagnetic Compatibility (EMC) to prevent electromagnetic interference and ensure that the product meets safety standards.

- Flame Retardant Performance. Battery connector’s housing and insulation materials must have flame-retardant properties (such as UL94 V0 rating) to prevent fire hazards.

Conclusion

Battery connector types hinge on specific application requirement. XT90 and Anderson series battery connectors boast high current handling capability while JST connector and PH2.0 shines in low current and voltage capability. EC series and Deans T-plug(T-type) battery connectors offer quick-disconnect ability with simple replacement and installment, scalability and flexibility. Additionally, IP rating protection, temperature range and certification are key considerations for selecting a safe and durable battery connector type.

FAQs about Lithium Battery Connector Types

What connector is best for lithium battery packs?

The “best” connector for lithium battery packs varies by application. Popular, dependable choices for higher current (RC, EV, Solar) include XT60/XT90, EC5/EC8, and Anderson Powerpoles. Their copper and brass materials for conductivity and plating for corrosion resistance. For smaller electronics, JST series are common; key factors include power requirements, vibration resistance, and ease of use.

How do I choose the right current rating for a battery connector?

To select the appropriate battery connector, match connector’s amp rating to system’s maximum current draw, selecting higher rating than required safety margin. It ensure voltage rating meets and exceeds the battery’s voltage, material quality (copper/brass) and environmental factors for safety.

Are XT60 or Anderson connectors better for high current?

Anderson Powerpoles are the best choice for high current because they are very durable, can handle a lot of vibration, and can handle a lot of consistent high loads. XT60 connectors are great for RC/drones because they are strong, simple, and often cheaper up to their 60A rating. The best choice depends on the environment, the amount of current needed (Andersons can handle more in larger sizes), and how easy they are to use (XT60s are faster to connect, Andersons are genderless but need orientation).

How to ensure battery connector safety in custom battery packs?

To ensure battery connector safety in custom packs, use rated connectors and multimeter to verify polarity, insulate exposed terminals with tape or heat shrink. Secure connections with proper torque, include Battery Management System (BMS) for monitoring, use correct wire gauges, and add appropriate fusing.

Can battery connectors affect BMS performance?

Yes, battery connectors significantly affect BMS performance by influencing power flow, heat dissipation, and communication. Poor quality or design leading to voltage drops, overheating, communication errors (like ground loops), and BMS failure. High-quality connectors are vital for reliable performance under difficult environments, ensuring accurate cell monitoring and balanced operation.