The recycling process of the battery is well worth it financially and environmentally. You may know that instead of throwing your old lithium-ion batteries in the trash, you are supposed to recycle them. But what happens when they get recycled? With all of the chemicals in a lithium-ion battery, it surely can’t be a simple process, right? In this article, we’ll explain exactly what happens to your lithium-ion batteries when they go through the recycling process. Here is what happens in each step of the process:

Battery Recycling Process: Re-processing

The reprocessing of the battery recycling process contains 5 steps: collecting, repairing and reusing, discharging, disassembling the battery pack, and shredding.

Collecting

Collect batteries from an electronics recycling or collection facility and then safely transport them to a processing facility to test whether the batteries can be reused. If they can be reused, they will be transferred to the pack production line. Otherwise, they will be treated as scrap batteries.

Repairing and Reusing

Batteries are then assessed to see if they can be repurposed. Sometimes they can be reused as is, sometimes they can be fixed by simply replacing a part, and sometimes they can be used for a new function, such as storing excess solar power from solar panels.

Discharging

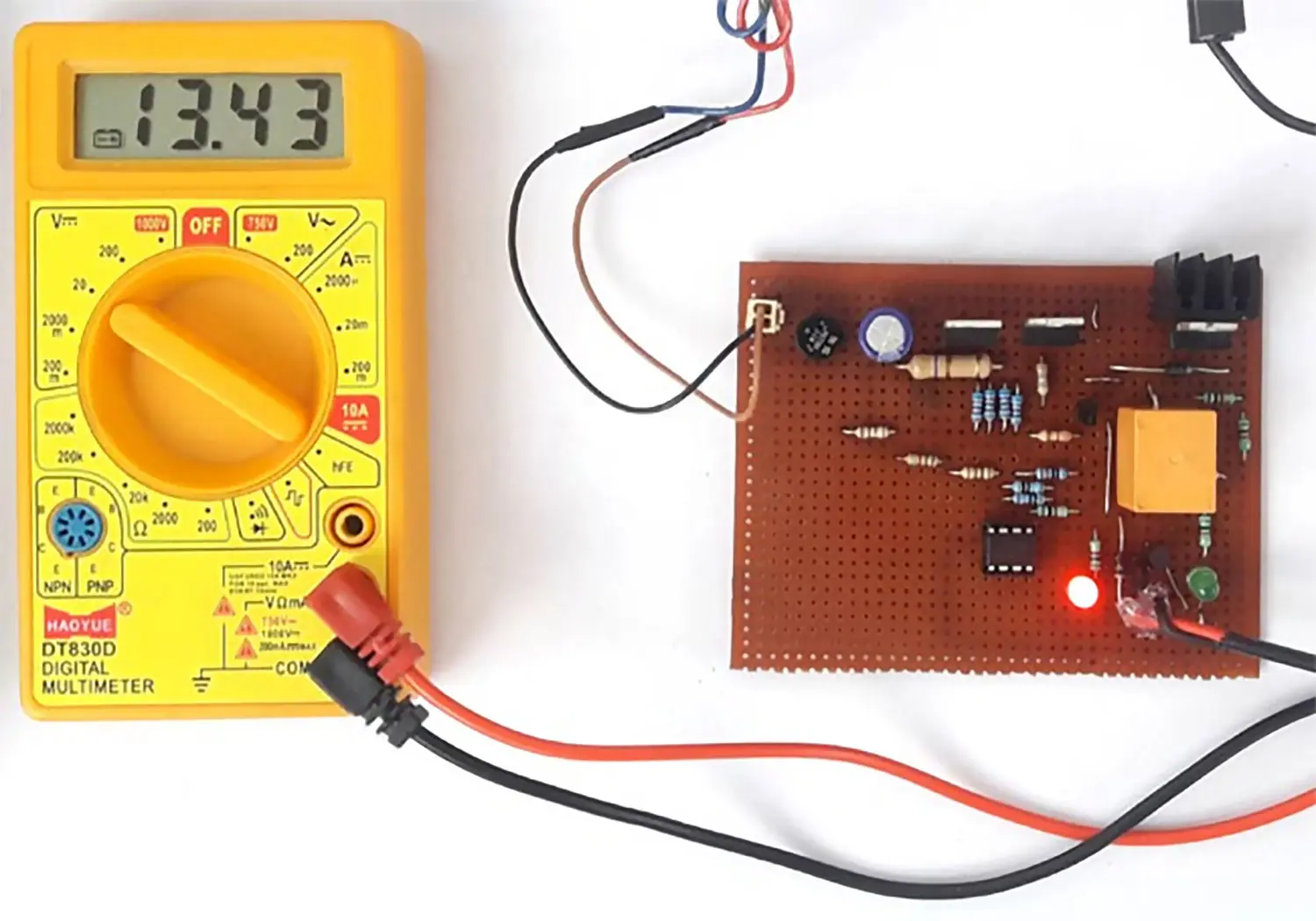

The next step for the batteries not being repaired or reused is to discharge all remaining electricity. This is often done by soaking the batteries in a brine solution, which is the cheapest method. Some alternative methods include thermal processing, cryogenics, and a closed-circuit resistor.

Disassembling Battery Pack

Disassembling battery packs and modules into single cells manually or mechanically. Then, further disassembling into components like positive electrode sheets, separators, and current collectors. Manual disassembly is used in laboratory research or workshop production, while large-scale industrial applications involve mechanical disassembly.

Shredding

The batteries are now shredded. The purpose of this shredding is to collect as much valuable “black mass” as possible, which can be used to make new cathodes and anodes. The shredded batteries are sifted to separate contaminants like copper, plastics, and other binders, leaving manufacturers with black mass.

Battery Recycling Process: Valuable Metal Recovery

The next step of the recycling process is to filter valuable metals out of the black mass. Pyrometallurgy, hydrometallurgy, and bioleaching are three common ways of doing this:

Pyrometallurgy

Smelting, also known as pyrometallurgy, uses high temperatures to extract the metals. The pretreated battery materials are roasted at high temperatures to decompose organic compounds and reduce metal oxides into metallic elements. Then, metals are separated through smelting, electrolysis.

Hydrometallurgy

Leaching, also known as hydrometallurgy, uses liquid solutions to extract the metals. Recycling these metals keeps them out of landfills, where toxins would contaminate groundwater over time. It also prevents miners from needing to mine more of these metals, providing a significant positive impact on the environment.

Bioleaching

Bioleaching: Utilizing microbial metabolism to selectively leach metallic constituents from batteries into solution. Acidithiobacillus ferrooxidans, for example, is used to leach cobalt and lithium from lithium cobalt oxide (LiCoO₂).

Battery Recycling Process: Manufacturing New Batteries and Post-processing

The last step of the battery recycling process involves two steps: Manufacturing a new battery and Post-processing.

Manufacturing new Batteries

These recycled materials are then shipped out to battery manufacturers, who will use them to make new batteries, completing the cycle. New battery materials, such as positive electrode materials, negative electrode materials, and electrolytes, are prepared based on the recycled metal compounds or metal elements through chemical synthesis, physical processing. Diisooctylphosphinic acid is often used as an extractant in this process to separate and purify metal ions

Post-treatment:

Treat the wastewater, waste gas, and waste residue generated during the recycling process to meet environmental protection requirements. For example, purify the leachate to remove impurities and harmful substances.

Unfortunately, while lithium-ion batteries are less toxic than lead-acid batteries, the recycling of lithium-ion batteries isn’t as common as lead-acid recycling yet. While it is a hugely beneficial process, both environmentally and economically, many places don’t have enough infrastructure yet for this process to be a common occurrence. However, as demand for lithium-ion batteries grows, so does the significance of establishing efficient and ecological recycling procedures. CMB is taking steps to promote safe and effective lithium-ion battery recycling.

For more information on lithium-ion battery processes and best practices, visit our website.

One thought