Medical device battery certification is an important aspect of ensuring the safe and reliable operation of battery-powered medical devices. Unlike common batteries, medical batteries must adhere to strict regulations to meet the specific medical device battery requirements environments. As one of the leading medical device battery manufacturers, CMB will shed light on various aspects of medical battery certification and address the safety of lithium-ion batteries in medical device applications.

Medical Device Battery Requirements for the Medical Application

Medical equipment batteries are an essential component of a wide range of life-saving and life-enhancing devices. From pacemakers and defibrillators to surgical instruments and portable diagnostic equipment, medical batteries are designed to meet the specific needs of medical devices and equipment. They offer higher standards of safety, performance, and reliability than standard batteries for applications.

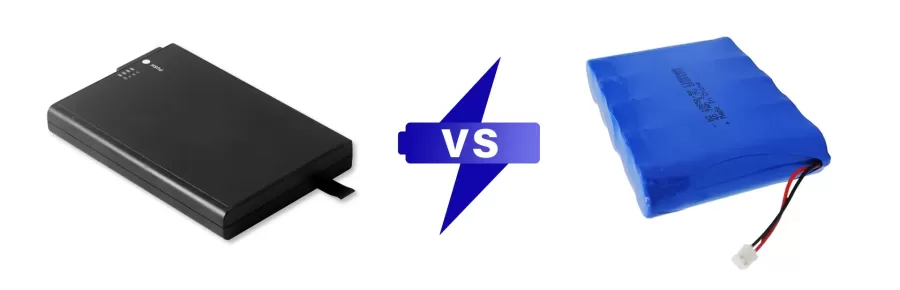

Differences between Medical Batteries and Standard Batteries for Other Applications

Medical batteries are specially designed to meet high safety requirements, ensuring reliable performance and lifespan in a wide range of medical applications. These batteries undergo strict testing to ensure that they can endure the challenging conditions of healthcare equipment, such as exposure to moisture, temperature fluctuations, and vibrations.

Here are some key differences between medical batteries and standard batteries for applications:

| Characteristic | Medical Batteries | Standard Batteries for Application |

| Change control | Yes | No |

| Emphasize | Safety, performance, and reliability | General-purpose |

| Cell protections | More robust | Less robust |

| Component quality | Higher | Lower |

| Electromagnetic environment compatibility | Yes | No |

| Autoclave cleaning compatibility | Yes | No |

| Authenticity | SHA-1/HMAC-based authentication | No authentication |

| Serialization and traceability | Yes | No |

Overall, Batteries in the medical field are designed to be safer, more reliable, and more performant than standard off-the-shelf batteries. They are also subject to stricter quality control and regulatory oversight.

Are Lithium-Ion Batteries Safe for Medical Device Applications?

Lithium-ion batteries have grown in popularity due to their high energy density, longer lifespan, and lightweight properties. However, safety concerns regarding lithium battery thermal runaway and the potential for fires have been raised. To consider these concerns, medical device battery manufacturers are required to meet additional safety standards and implement measures to minimize risk. By adhering to strict guidelines and incorporating safety features, medical-grade lithium-ion batteries can be used safely in medical device applications.

What are the Battery Packs for Medical Devices Qualification Standards?

Medical device batteries must meet several qualification standards to be placed on the market. These standards are designed to ensure the safety, reliability, and performance of the batteries.

- Safety regulatory requirements: Medical device batteries must meet all applicable safety regulatory requirements. These requirements vary depending on the type of medical device and the jurisdiction in which it is being sold. For example, stand-alone battery-powered medical products have different requirements than battery-powered products close to the patient.

- Transportation requirements: Medical device batteries must be transported by all applicable transportation regulations. These regulations are designed to ensure the safety of the batteries during transport.

- Design features required to meet these regulatory requirements: Medical device batteries must be designed to meet all applicable safety and performance regulatory requirements. This may include features such as overcharge protection, thermal shutdown, and biocompatibility.

- Going beyond just meeting regulatory, designing features to mitigate patient risk: Medical device manufacturers should go beyond just meeting regulatory requirements when designing their batteries. They should also incorporate features that help to mitigate patient risk, such as battery management systems and battery health monitoring systems.

Medical Device Battery Requirements for Certificates

FDA General Safety and Performance Requirements (US):

- Batteries must meet the safety requirements of IEC 62133, UL 2054, ISO 13485, and IEC 60601-1.

- Batteries must be biocompatible.

- Batteries must have safety features for use near patients.

- Batteries must be able to be authenticated to prevent counterfeiting.

- Batteries must be serialized and traceable.

The United States Food and Drug Administration (FDA) has specific requirements for batteries used in medical devices, which include safety considerations, labeling, and testing.

European Medical Device Regulation (EU):

The EU has its own set of regulations (MDR) that medical device batteries must comply with for safety, performance, and quality.

- Batteries must meet the essential safety and performance requirements of the MDR (Annex I).

- Batteries must be biocompatible.

- Batteries must be designed and manufactured in accordance with a quality management system that meets the requirements of ISO 13485.

- Batteries must be tested and evaluated to ensure that they meet all applicable requirements.

In addition to these medical device battery requirements, there may be specific requirements for batteries used in certain types of medical devices. For example, batteries used in implantable medical devices may have additional safety and performance requirements.

- IEC 62133: This standard is an international standard for the safety of secondary cells and batteries containing alkaline or other non-acid electrolytes. It covers the same general safety requirements as UL 2054, but it also includes additional requirements for medical device batteries, such as biocompatibility and safety features for use in close proximity to patients.

- UL 2054: This standard is a safety standard for household and commercial batteries, but it is also widely used for medical device batteries. It covers a wide range of safety requirements, including electrical safety, mechanical safety, environmental safety, thermal safety, and performance.

- IEC 60601-1: This standard sets the general requirements for the basic safety and essential performance of medical electrical equipment, including batteries.

- ISO 10993-1: This standard provides guidelines for evaluating the biological safety of medical devices, including batteries, by assessing potential risks related to cytotoxicity, genotoxicity, and other factors. This means that the batteries have been tested to ensure that they are not likely to cause adverse biological reactions in patients.

- ISO 13485: The qualification for medical device batteries demonstrates that the manufacturer has a quality management system in place to produce safe and reliable batteries. This includes having processes in place to identify and mitigate risks, validate the batteries, and control the design, manufacturing, and servicing of the batteries.

These are just a few of the commonly referenced standards and regulations. Medical device battery manufacturers must consult and comply with the applicable regulations in their target markets to ensure the batteries used in their devices meet the required qualification standards.

By meeting these qualification standards, medical device manufacturers can help to ensure the safety and reliability of their batteries and protect patients from harm.

Medical Batteries Safety Certification for Transportation

To guarantee the safe transportation of lithium, lithium-ion, and lithium polymer batteries, there are stringent international regulations in place. These regulations mandate that these batteries must undergo certification to a separate transportation safety test standard and comply with the requirements outlined in the United Nations document ST-SG-AC10-11 “Recommendations for the Transportation of Dangerous Goods – Tests and Manuals”, specifically section UN38.3.

Conclusion

At CM Batteries, we work closely with each customer to identify the most appropriate certification body, applicable standards, and additional testing necessary for their specific product, intended use, and target market. It is important to note that some clients may request unnecessarily high certification standards, resulting in higher testing costs, or outdated standards as new versions are introduced and refined.

To ensure an efficient and successful process, we recommend that customers reach out to us early in the development stages with their requirements. This allows us to determine the specific needs of their product, chosen market, and application.

In conclusion, the safety and certification of medical device batteries play a vital role in the healthcare industry. Understanding the differences between medical batteries and standard off-the-shelf batteries, ensuring the safety of lithium-ion batteries used in medical devices, adhering to specific qualification standards,

As one of the leading medical device battery manufacturers, CMB’s production complies with safety medical device battery requirements and obtains the necessary safety certifications for transportation. Contact us for battery guidance for medical applications.

3 thoughts

Thanks for the message and site bookmarked! We are glad that our blog can be of help to you!

Thank you for your comments, I’m glad I was able to help you. All the best to you and your roommate.

Thank you for your message, the community is a better place because of you. Very happy to be of help to you!