Like all great pieces of technology that drastically improve our daily lives, lithium-ion batteries also have their shortcomings. However, as lithium-ion battery experts with decades of experience, we pride ourselves in our belief that for every challenge, there is always a solution. Understanding the challenges of battery technology is essential to properly understanding the lithium-ion battery industry as a whole. In this article, we’ll review the biggest challenges of lithium-ion batteries and the solution to each one.

Challenges of Battery Technology: Safety Hazards

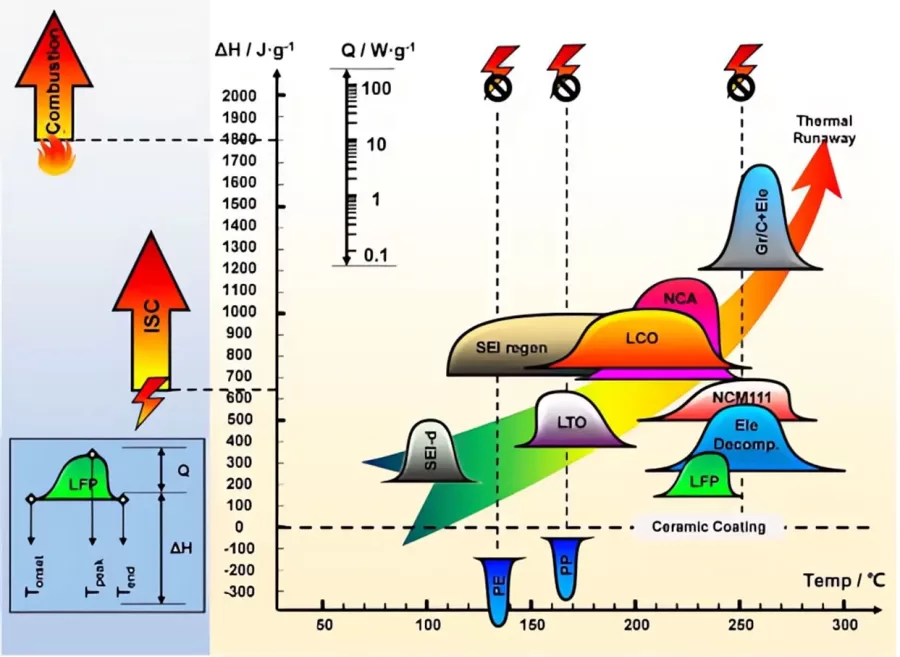

The liquid state electrolyte of a lithium-ion battery can be potentially hazardous if not cared for properly. Specifically, lithium-ion batteries become dangerous when their temperature rises too fast, leading to lithium battery thermal runaway, which can result in fires or explosions. Similarly, overcharging or over-discharging your battery can also lead to dangerous situations.

Solution: Smart BMS

To avoid safety hazards, manufacturers can install a reliable smart battery management system (smart BMS) to monitor the temperature of the battery. This way, users can be warned of increasing battery temperatures before they become a problem. Smart BMSs also prevent batteries from overcharging by cutting off the connection once the charge is full and will warn users when the battery is close to over-discharging, which can cause short circuits and fires.

CMB’s BMS solutions offer comprehensive monitoring, including cell voltage tracking, cell balancing, and detailed health status readings for the entire battery pack by App and PC upper computer.

Challenge: Environmental Risk

Lithium extraction causes environmental issues, such as depleting underground water levels or destroying habitats. In addition, the incorrect disposal of lithium battery waste can emit toxic chemicals that cause dangerous water pollution.

Solution 1: Use More Accessible Materials

Scientists are hard at work developing battery constructions that require less lithium. For example, a recent AI-driven venture has found that sodium, which is much more accessible than lithium, can be used as a combination material to reduce the amount of lithium needed for lithium-ion batteries. These developments help decrease the environmental impact of lithium-ion batteries over time.

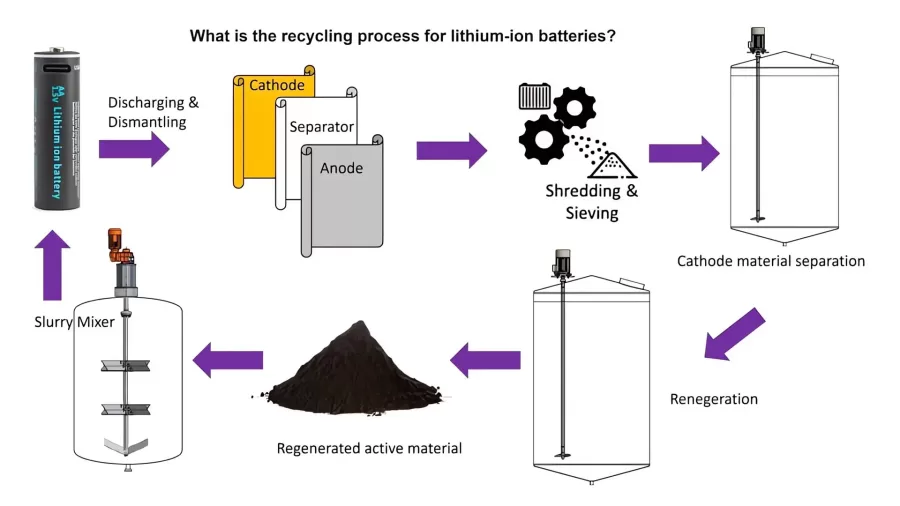

Solution 2: Better Waste Disposal Protocols

This solution requires better programs, and also better education for companies and individuals who use lithium batteries often. Here is a closer look at the proper lithium-ion battery recycling process. This recycling process vastly reduces the amount of toxic pollution and reduces the need to extract more lithium from the earth. Since lithium-ion batteries have become so popular, more certified battery recycling centers should be soon to follow.

Challenge: High production costs

Producing lithium-ion batteries is an expensive process, and this cost gets passed down to the consumer. Prices come down when lithium-ion batteries are produced at scale like they are at CMB, but they’re still more expensive than lead-acid batteries (even though they last longer and are more efficient, saving you money in the long run!). What can we do about this?

Solution: AI

Manufacturers, including CMB, are using artificial intelligence (AI) to improve production efficiency and drive costs down for consumers. AI can process infinite amounts of data to pinpoint inefficiencies and build models to improve production, ultimately saving consumers money.

Challenge: High Costs of Hydrogen Fuel Cells

Hydrogen fuel cells and hydrogen generators are expensive due to costly materials like platinum and complex manufacturing processes. These high costs make them less competitive compared to alternatives like lithium-ion batteries, even when produced at scale.

Solution: AI and New Materials

Manufacturers use AI to improve efficiency, reduce waste, and enhance precision in producing hydrogen fuel cells and hydrogen generators. AI is also helping discover cheaper alternatives to costly materials like platinum, ultimately lowering costs and making these technologies more affordable and sustainable for consumers.

Using an established manufacturer like CMB will ensure that these common concerns are being addressed effectively by experienced professionals. CMB utilizes the latest technology and developments in the design and manufacturing of custom lithium-ion battery packs, and we continue to research and develop novel solutions to issues facing the battery industry. Contact us to learn more about what CMB has to offer.