As high-power applications such as drones, robotics, fast-charging systems, and industrial equipment demand higher discharge rates and thermal stability, traditional winding battery structures are facing performance limitations. Engineers often struggle with voltage drop, overheating under high load, or limited fast-charging capability. In such scenarios, stacked battery technology is gaining attention. But is stacking always better than winding? And how should you choose for your high-rate battery project?

Typical Applications Requiring High-Rate Battery Performance

Not all devices require high-rate discharge. But for certain applications, battery structure directly impacts performance and safety. Below are typical high-rate scenarios where cell assembly technology becomes critical:

Drones require rapid power bursts during takeoff, climbing, and maneuvering. High C-rate discharge and stable voltage output are essential to avoid mid-air instability.

Industrial and service robots experience frequent peak current demands during motion control and acceleration. Poor current handling can lead to voltage sag and system resets.

Power tools operate under sudden heavy loads. The battery must deliver high instantaneous current without overheating.

Defibrillators and portable medical systems require both fast discharge and absolute reliability under emergency conditions.

Automated guided vehicles require stable high-current discharge and efficient thermal management for continuous operation. If your application involves frequent high current discharge (above 3C–5C), the internal structure of the battery cell becomes a key design factor.

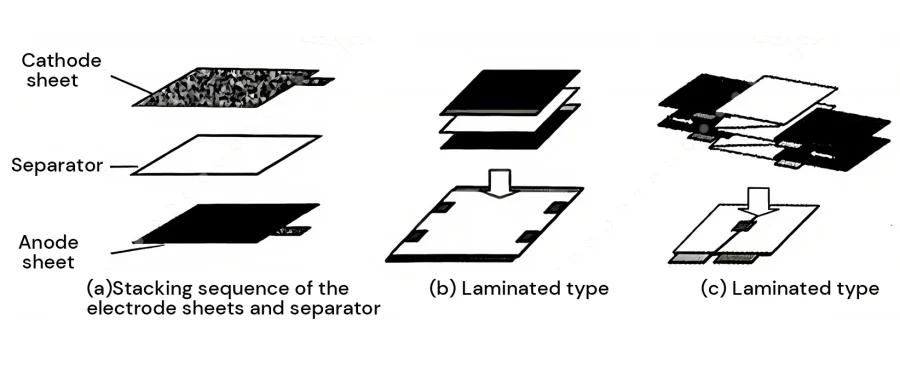

What is Stack Battery Technology?

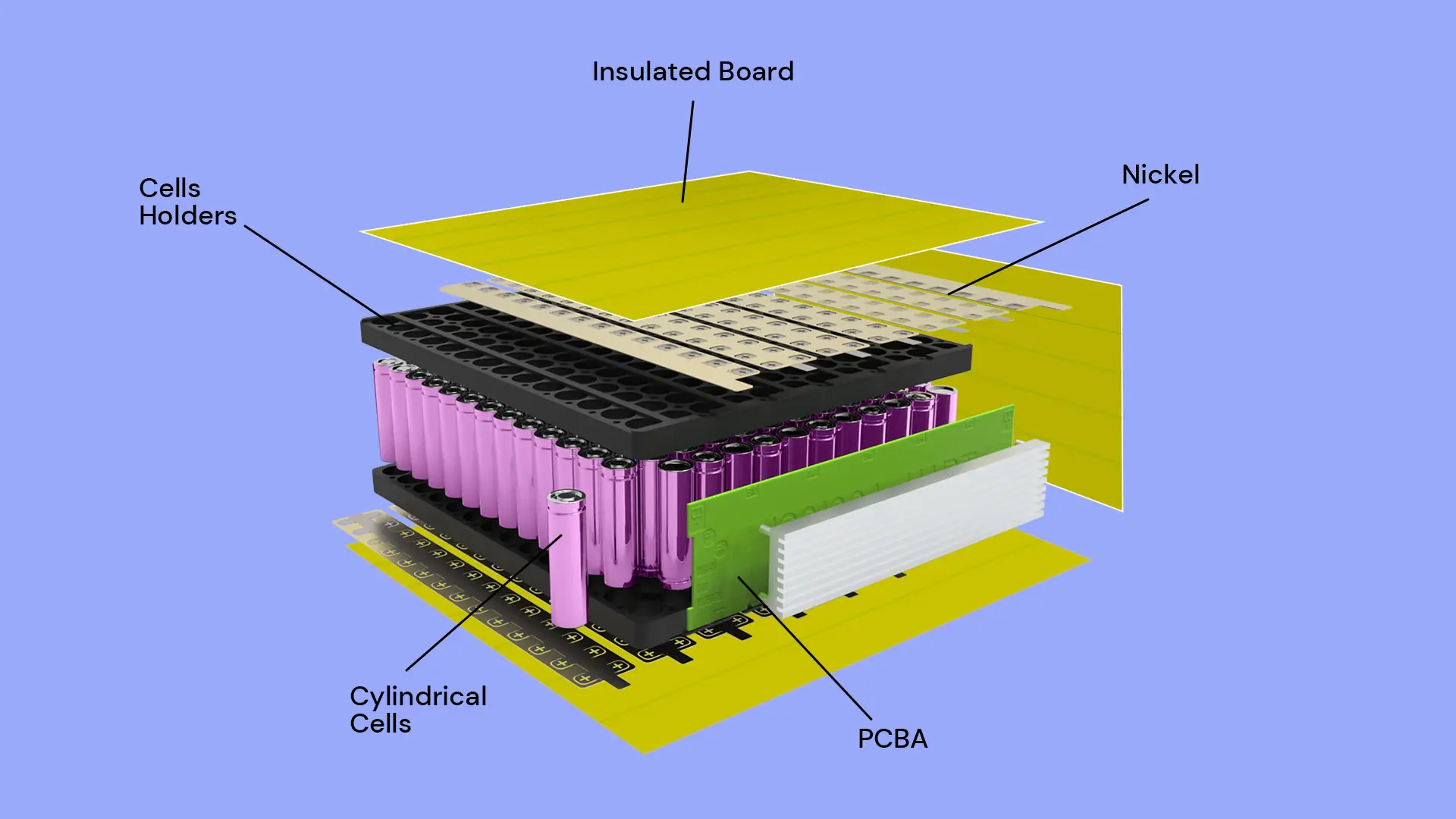

Stacking battery technology involves using current collector as the lead tab, and stacking the positive electrode, separator, and negative electrode in a sequence of positive, separator, and negative to form a stacked cell. There are two main stacking methods: one is the direct stacking method where the separator is cut, and the other is the Z-shaped stacking method, which folds the separator without cutting it. Both stacking and winding processes are capable of full automation and are mature cell assembly technologies.

The structure of the stacked cell ensures that each tab has a corresponding ear, resulting in lower internal resistance, making it more suitable for high-current charge and discharge. Additionally, stacked cells have high space utilization. Compared to wound cells, stacked cells have inherent advantages in the design and manufacturing of large batteries, ultra-thin batteries, and irregular-shaped batteries.

The stacked structure distributes the force evenly, with lower expansion rates, smoother current flow, and longer cycle life. However, stacking process is more complicated and involves multiple tabs, which increases the risk of poor welding. Compared to winding equipment, stacking machinery requires high precision, has higher costs, and is slower in production speed.

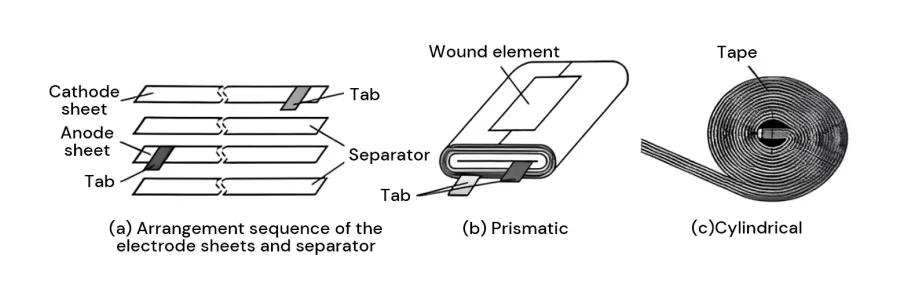

What is Winding Battery Technology?

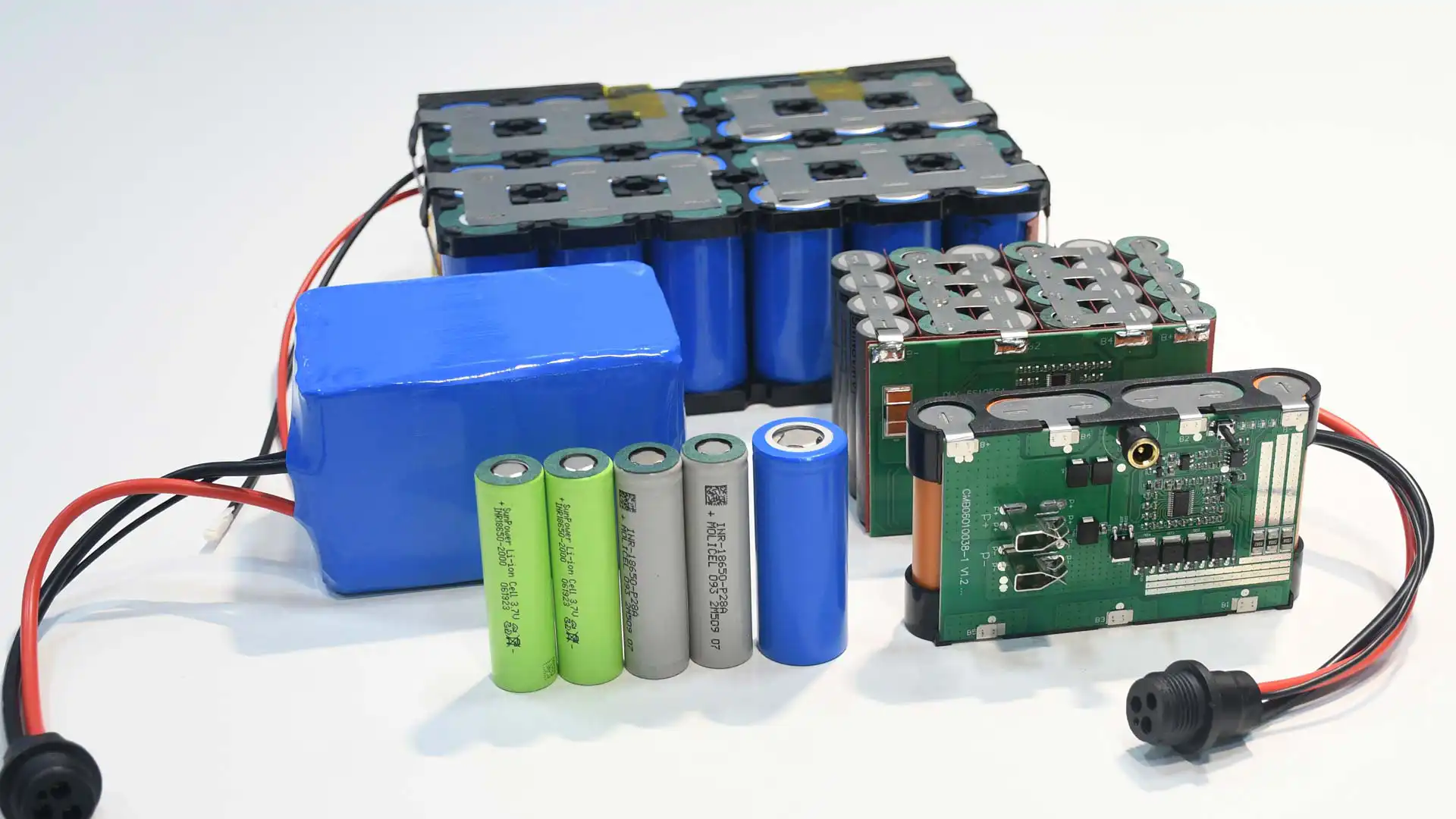

Winding battery technology involves welding the tabs onto the current collectors using ultrasonic welding. The positive electrode tab is made of aluminum, while the negative electrode tab is made of nickel. The positive and negative electrode sheets and separators are arranged in the sequence of: positive electrode, separator, negative electrode, separator, and wound together to form the cell. The winding process is used technology in lithium-ion battery production, ideal for cylindrical cells and square cells manufacturing.

Lithium-ion batteries, as the core technology of modern energy with highly mature winding technology. Today, the construction of wound cells uses fully automated production equipment. The materials used are aluminum and nickel, which keep the production cost low and the utilization rate high, making winding an essential step in lithium-ion battery assembly.

The winding structure gives cylindrical batteries compressive strength and higher safety. However, one downside is that electrodes blending during winding creates dead spots, causing battery inefficient space. Additionally, the single tab design results in higher internal resistance, which is not ideal for high-current charge and discharge. Therefore, wound cells are suitable for small square and cylindrical batteries.

Why High-Rate Batteries Prefer Stack Battery Technology?

High-rate batteries, such as power batteries and fast-charging batteries need to maintain high efficiency, stability, and safety during high-current charging and discharging, placing higher demands on manufacturing processes. Stacking process are replacing the traditional winding process in high-rate batteries. Stacking battery technology have lower resistance, superior energy density, better stability, and longer cycle life, ideal for robots, drones and power tools.

Shorter Current Path, Lower Internal Resistance

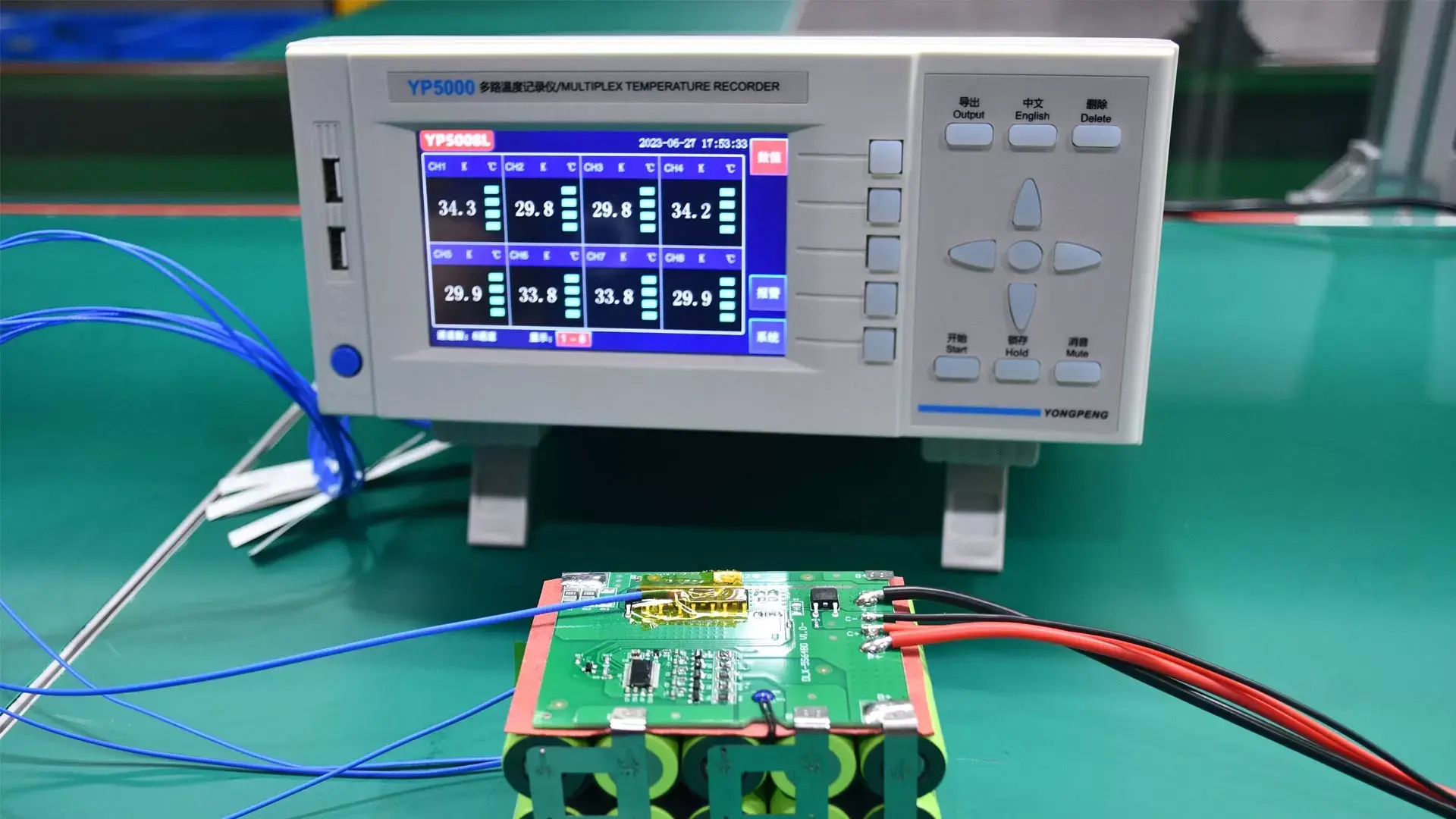

During high-rate charge and discharge, battery needs to withstand larger currents, and the current path length affects internal resistance and heat generation.

- Winding battery technology. Current travel along the length of the electrode, resulting in longer path, higher internal resistance, and noticeable energy loss and heat generation at high currents.

- Stacked battery technology. Its positive and negative electrodes are stacked in parallel, and the current needs to pass vertically through the thickness of the electrodes, shortening the path, reducing internal resistance, and making it more suitable for high-rate charge and discharge.

Higher Energy Density, Better Space Utilization

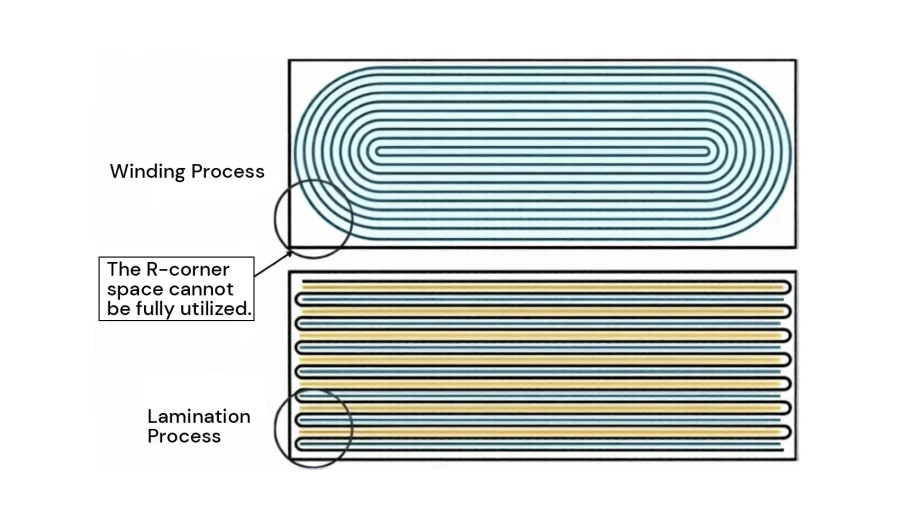

The energy density of the battery directly affects its range and performance, and the stacking process has a greater advantage in space utilization.

- Winding battery technology. Cavity forms at the center of the cell, causing space waste and limiting energy density.

- Stacked battery technology. The electrodes are neatly stacked without central cavity, resulting in high space utilization and increased 5%-10% energy density.

Better Mechanical and Thermal Stability

- High-rate batteries generate more expansion and heat during charge and discharge, and the stacking process handle these issues.

- Even Stress Distribution. Stacking structure evenly distributes stress across the electrodes, reducing deformation or separator wrinkling caused by uneven expansion.

- Better Heat Dissipation. Heat is distributed more evenly, avoiding local overheating.

Longer Cycle Life

High-rate batteries tend to age faster with frequent high-current charge and discharge, and the stacking process helps extend their lifespan.

Reduced Interface Degradation: The stacking structure minimizes the loss of active material caused by electrode bending, increasing cycle life by 10%-20% compared to the winding process.

Adaptability to Large and Irregular-Shaped Battery Designs

As batteries evolve towards larger sizes and customization, the stacking process offers greater flexibility.

- Winding Process: Large-sized cells are prone to deformation, affecting performance.

- Stacking Process: Can accommodate designs such as blade batteries and irregular-shaped cells, meeting the needs of different application scenarios.

Challenges of the Stacking Process

- Lower Production Efficiency. Stacking requires precise alignment, and the production speed is slower than winding.

- High Equipment Cost. Stacking machines are more complex than winding equipment, requiring a larger initial investment.

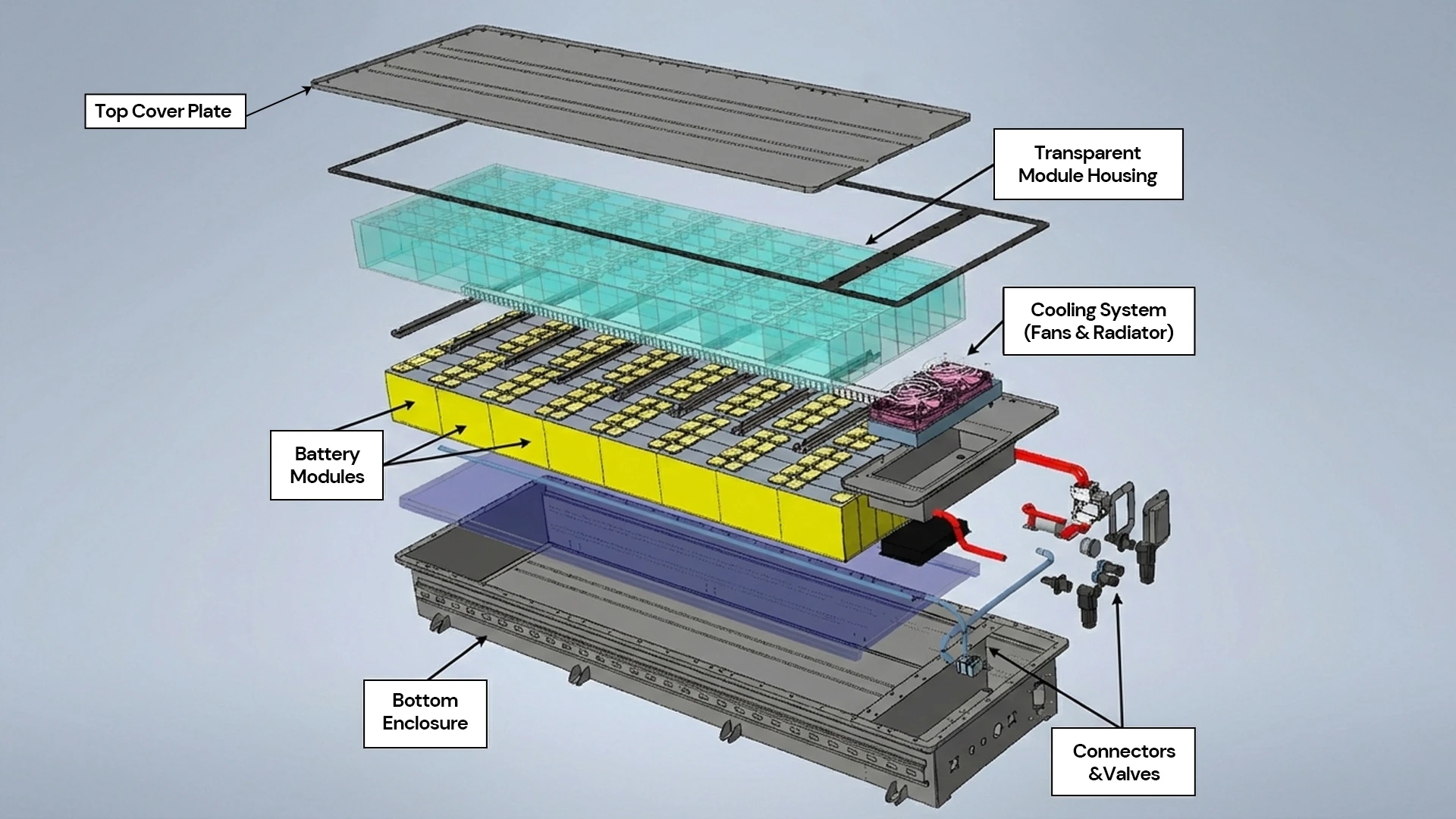

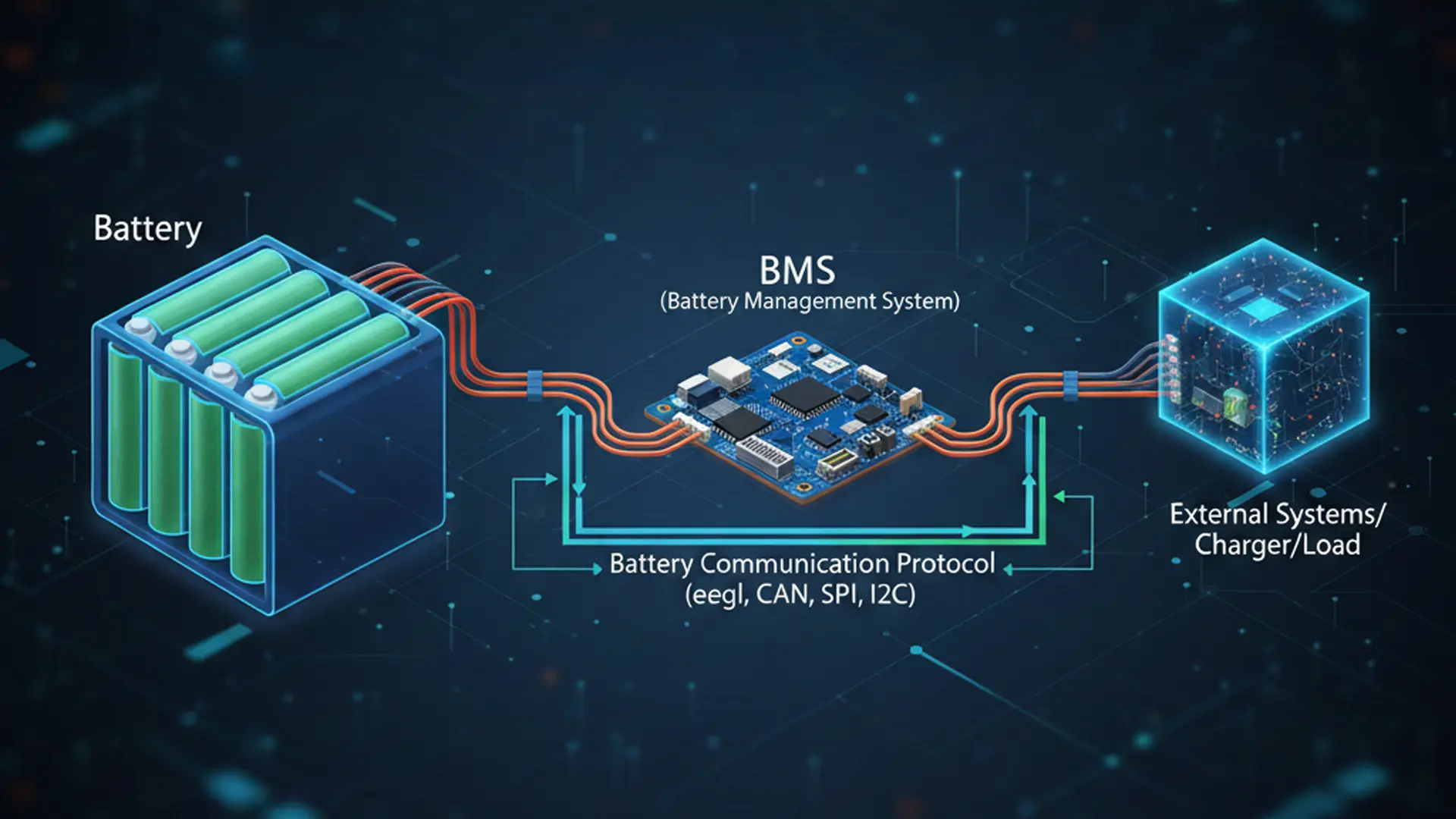

In practice, selecting stacking technology alone does not guarantee high-rate performance. The integration of cell assembly with pack-level engineering design is equally critical.

Stack Battery Technology Classification

Z-type stacking, cut-stack integrated, thermocomposite stacking, and roll-stack integrated are four major lithium-ion battery stacking technologies. Understanding their working principle contributes to enhancing stacked battery design efficiency.

Z-type stacking Technology

Z-type stacking technology is used stacking process, which works by moving the separator back and forth between the stacking platforms, achieving the cross stacking of the positive and negative electrodes. It has the following issues:

- Separator deformation: The separator moves with the stacking platform, causing asymmetry and deformation, which affects battery quality. Additionally, the separator’s porosity and specific surface area fluctuate.

- Low stacking efficiency: The separator needs to swing during stacking, increasing time per stack, and achieves single-piece stacking.

Cut-stack Integrated Technology

- Improved yield: By consolidating multiple processes into one machine, the risk of damage during transfer is reduced. Traditional methods involved handling electrode sheets separately, which causes damage. The integrated machine combines cutting, Z-type stacking, and adhesive hot-pressing, minimizing handling and improving yield.

- Improved stacking efficiency: The machine simultaneously feeds electrodes and separators, stacking them in Z-pattern. After reaching the set number of layers, the separator is cut, glued, and hot-pressed to form the cell. For example, Xianxian Intelligent achieves 800PPM (0.075s/pcs), while Liyuanheng’s machine reaches 0.15s/pcs (three stations).

Thermocomposite Stacking Technology

The thermocomposite stacking machines feed electrodes and separators simultaneously. The electrodes are cut, heated, and pressed together, forming composite units that are stacked and hot-pressed into the core. The separator is adhesive-coated, becoming sticky when heated, which helps bond the layers during the process.

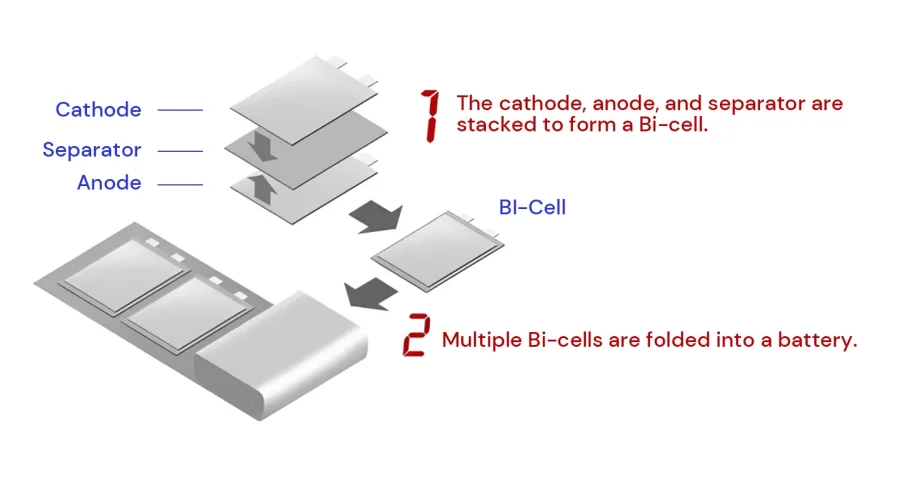

Roll-stack Integrated Technology

LG holds the Stack & Folding patent with equipment provided by the German company MANZ. The process cuts the positive and negative electrodes into units, which are placed on separators and wrapped in winding method to alternately stack the electrodes. This method offers high speed and efficiency.

LG’s Stack & Folding patent stacks one positive electrode, one negative electrode, and one separator to form a Bi-cell, then folds multiple Bi-cells to create the battery. LG also uses its SRS (Safety Reinforced Separator) technology, which coats the separator with ceramics to increase strength and prevent short circuits.

Battery Stacking and Winding Technology Development Trends

High-speed stacking machines and dry electrode technology of battery stacking technology remove solvent coating and presses the electrode sheets. This innovation aims to address high equipment costs.

Winding technology process focuses on improving space utilization and energy capacity. The current pre-bending technology pre-forms the electrode sheets into specific curvature, reducing the stress during winding. Multi-tab winding design reduces internal resistance.

The competition between winding and stacking processes is a balance between efficiency and performance. Like the preference for rolled cakes versus layered biscuits, the two processes need to coexist in different applications, evolving through mutual refinement. By optimizing the structure of winding to improve energy density and utilizing stacking + winding hybrid process, enhancing efficiency.

Conclusion

Selecting between winding and stacking requires comprehensive evaluation of discharge profile, thermal load, spatial constraints, and lifecycle expectations.

For project-specific assessment or high-rate battery pack engineering consultation, you may discuss with CM Batteries technical team here: https://cmbatteries.com/contact/