With battery technology growing, 18650 cells in powering various electronic devices and systems play important roles. We will share the customization process -design, manufacture, and applications of 18650 rechargeable battery packs. To meet the diverse requirements, customized 18650 battery packs offer flexibility, high performance, and cost-effectiveness.

Rechargeable 18650 Li-ion Cell Knowlege

Before delving into lithium-ion rechargeable battery packs, it is important to have a clear understanding of 18650 batteries. They are also a very popular type of battery in the market because of their cost-effectiveness and wide usage for many types of products.

Size and Shape:

The term “18650” refers to the dimensions of the cell, where “18” represents the diameter in millimeters (18mm) and “65” represents the height in millimeters (65mm).

The cylindrical shape with standardized dimensions is easy to integrate into the various devices and battery pack holders.

Chemistry:

18650 cells typically use lithium-ion chemistry, which involves the movement of lithium ions between the positive (cathode) and negative (anode) electrodes during charge and discharge cycles.

Different chemistries, such as lithium cobalt oxide (LiCoO2), lithium manganese oxide (LiMn2O4), lithium iron phosphate (LiFePO4), and lithium polymer, offer different performance in performance, energy density, safety, and cost.

Voltage and Capacity:

The nominal voltage of a single 18650 cell is typically 3.6 to 3.7 volts, with a fully charged voltage of around 4.2 volts.

The capacity of an 18650 cell is measured in milliampere-hours (mAh) and represents the amount of charge it can store. Typical capacities range from a few hundred mAh to several thousand mAh.

Energy Density:

18650 cells are known for their high energy density, which refers to the amount of energy they can store per unit of weight or volume.

Higher energy density allows for more energy storage in smaller and lighter battery packs, making 18650 cells ideal for portable electronic devices and applications where space and weight are critical.

Cycle Life:

Cycle life refers to the number of charge/discharge cycles a battery can undergo before its capacity significantly degrades.

Good quality 18650 cells can typically handle several hundred cycles or more, depending on the specific chemistry and usage conditions.

When we are familiar with the characteristics and considerations associated with 18650 Li-ion cells, our engineering team needs to make choose the right cells and assemble the battery packs for the devices.

Advantages of Rechargeable Battery Pack

Customized 18650 battery packs make it happen to meet specific requirements by tailoring voltage, capacity, cell configuration, and discharge rates. The custom solutions offer the following benefits:

- Flexibility and Versatility: Custom rechargeable battery packs offer flexibility and versatility in terms of their design and applications. They can be tailored to fit specific device requirements, ensuring compatibility and optimal performance. Additionally, they can be used in a wide range of devices and applications, from consumer electronics to medical devices and electric vehicles.

- Safety: Custom lithium ion battery packs can be designed with integrated battery management systems that offer overcharge protection, short circuit protection, and temperature control. They prevent battery packs and devices from damage even fires.

- Advanced Performance: By optimizing power delivery and capacity, customized packs provide optimal performance for specific applications.

- Cost-effectiveness: While rechargeable battery packs may have a higher upfront cost, they can lead to significant long-term cost savings. By eliminating replacing one new battery pack, especially in high-drain devices or applications, the overall cost will be reduced instead of replacing one new device.

- Easy Maintenance: Custom rechargeable battery packs are generally easy to maintain. They are easy to be compatible with the charging systems. Besides, we can monitor our battery health by LED display and APP.

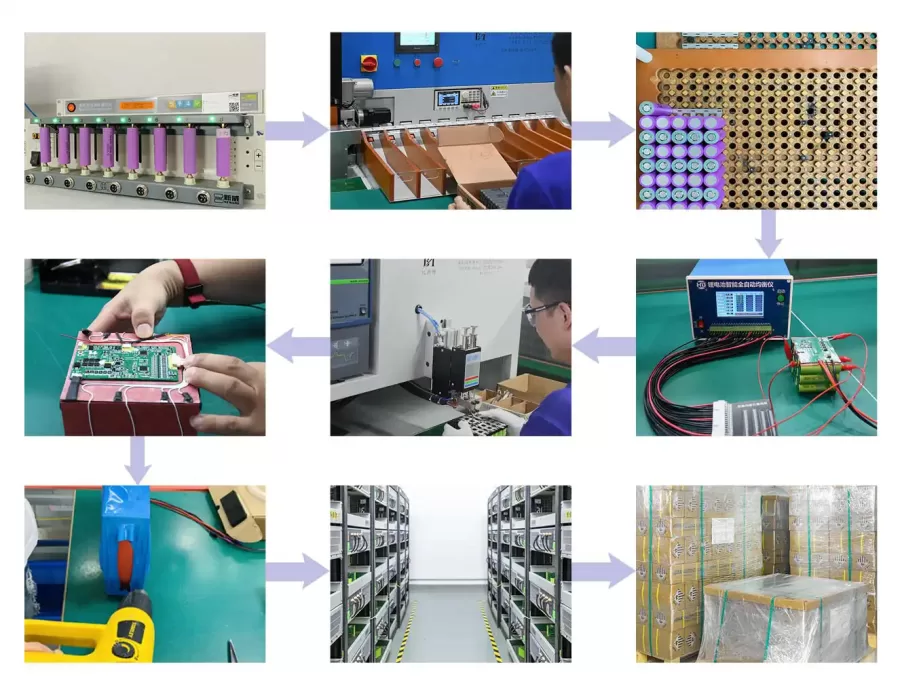

Design and Manufacturing Process of Rechargeable 18650 Battery Packs

First, the battery pack design process begins with determining the specific requirements. You should make it clear the main factors such as voltage, capacity, and discharge rates. Once your customization questionnaire is filled, the engineer will confirm the suitable capacity, internal resistance, max discharge rate, and working temperature of 18650 cells.

Your pack configurations depend on your desired dimensions. The optimal internal resistance and insulations are the key factors for the assembled battery packs. The rechargeable 18650 battery packs are welded by nickel straps and soldered by wires in series and parallels to utilize for your specific needs.

Thermal protection should be considered in battery pack design. Heating decreases the battery performance and lifespan. The battery pack engineer thinks about how to dissipate the heating effectively. What is more, when we make the battery pack, we should consider the thermal pads or heat sinks, as well as designing airflow channels.

Safety measures are also incorporated into the design. This includes using protection circuitry to prevent overcharging, over-discharging, and short-circuiting. Fuse and temperature sensors may also be included to enhance safety.

In the following process, we will discuss the production process. It involves a combination of automated and manual assembly processes. The cells are assembled into the battery holders and connected in the configuration by hand. Welding and soldering processes make strong and reliable connections between the cells.

During the battery manufacturing process, the QC staff will inspect the whole process with tools to measure the data as per the specification and the li-ion battery standard of GB31241-2022.

Packaging is also an important aspect of the manufacturing process. The battery pack is typically housed in a custom-designed enclosure that provides both physical protection and insulation. The package is designed to allow for easy and safe handling, as well as efficient heat dissipation.

Overall, designing and manufacturing rechargeable 18650 battery packs involves careful consideration of various factors, including cell selection, pack configuration, thermal management, safety measures, and adherence to regulations. They ensure the production of reliable and safe battery packs that meet specific performance requirements.

Application Scenarios of Rechargeable Lithium Battery Packs

To illustrate the practical aspects of customizing 18650 battery packs, we will explore a case study involving the design of custom ebike batteries for an electric bicycle.

In this case study, we will focus on the design and customization of a 36V 14.5Ah frame battery for an electric bicycle. The battery pack is designed to meet specific requirements and provide optimal performance. Here are the details:

Product Code: CMB10040001

Installation: Frame Battery

Power Capacity: 522Wh (36V 14.5Ah)

Weight: 4kg

Dimension: 88*86*380mm

Charging time with 4A charger(50% charge/100% charge): Approx 1.7h/approx 4.6h

Description:

- The battery pack is made using DMEGCINR 18650-29E 3C cells, which are known for their high performance and reliability.

- The cells are chosen for their specific discharge rate capabilities, ensuring they can provide the required power for the electric bicycle.

- The battery pack incorporates a high-performance 304 BMS (Battery Management System) that monitors and protects the cells from overcharging, over-discharging, and other potential issues. This BMS ensures the safe and efficient operation of the battery pack.

- The battery pack is equipped with low-temperature charge protection, which helps maintain optimal charging performance and protects the cells from damage in cold conditions.

- The battery pack comes with a 24-month warranty, providing customers with confidence in the product’s quality and durability.

By customizing the 36V 14.5Ah frame battery according to these specifications, customers can get a reliable and high-performance power source for their electric bicycles. The inclusion of safety features, warranty, and the world’s most reliable cells enhance the overall value and customer satisfaction.

We have a variety of 36V 10Ah and 36V 20Ah e-bike batteries available, but if you want a custom-designed battery, our CTO can give design options using the world’s most reliable cells. We provide high-quality and low-cost Samsung 36V e-bike battery cells as well as Panasonic 36V e-bike battery cells. Additionally, we will touch upon potential application scenarios for customized 18650 battery packs, such as powering portable electronics and consumer devices, energy storage systems, electric vehicles, robotics, and integration into renewable energy systems. The versatility of customized solutions allows for a wide range of applications.

Conclusion

18650 rechargeable battery packs offer numerous advantages and play a crucial role in addressing diverse user requirements. By considering factors like voltage, capacity, cell configuration, and safety measures during the design and manufacturing process, optimal performance and user experience can be achieved. With their wide range of applications, custom 18650 battery packs are set to become even more relevant in the future of battery technology.