When you need to operate battery-powered devices in extremely cold temperatures, you must ensure both the machine and its power source can handle such harsh conditions. Cold environments significantly impact battery performance, so selecting the right battery becomes crucial for safe, effective, and long-lasting operation.

To choose the best battery for extreme cold, you should understand how low temperatures affect different battery types and identify which technologies can maintain reliable performance in these challenging environments. Some batteries excel in cold conditions while others fail quickly, making proper selection essential for mission-critical applications.

In this article, we’ll cover all of that to help you select a product that meets your exact needs.

How do Low Temperatures Impact Lithium Batteries?

Put simply, extremely low temperatures slow down the chemical reactions that occur within a battery, leading to poor performance and permanent damage. In such conditions, charging capacity decreases, while internal resistance increases. All of this results in shorter run times, reduced battery life, and battery failure.

To prevent these issues, common lithium batteries have a recommended temperature range of -20°C and -55°C. For conditions outside that range, you need special low-temperature batteries to ensure safety and battery longevity.

Is Low Temperature Damage to Lithium Batteries Permanent?

Because extremely low temperatures create chemical reactions within standard lithium batteries that are irreversible, the resulting damage is permanent. To understand what exactly occurs within the battery and how, let’s start with some basics.

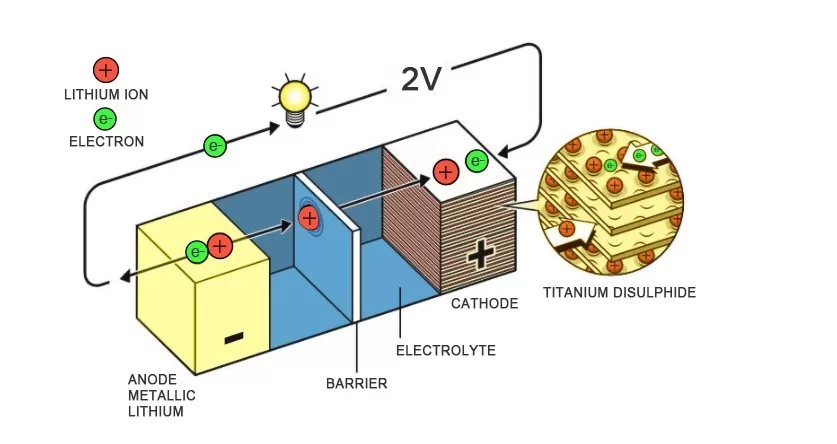

Lithium-ion batteries have one positive electrode and one negative electrode. During charging, lithium ions begin their journey at the positive electrode lattice, travel through the electrolyte separator to the negative electrode, and embed themselves into the graphite layers.While discharging, the reverse happens: lithium ions travel from the graphite negative electrode layer to the positive electrode lattice.

When exposed to low temperatures, everything slows down, from the movement of the molecules being transported, to the reaction speed, to the material transport process as a whole.

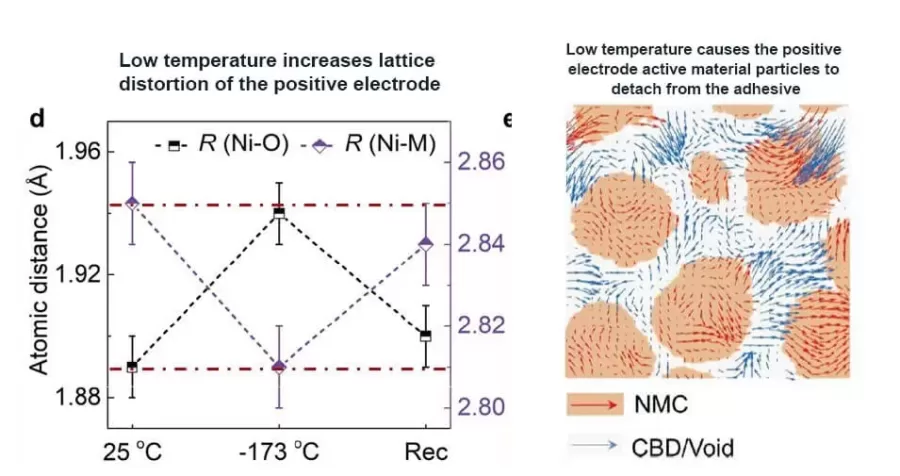

This slowdown is especially true for the lithium ions and lithium atoms in the graphite layers and positive electrode lattice. Lithium begins to accumulate at the electrode-electrolyte interface instead of being embedded into the graphite layer, which results in the formation of lithium dendrites (metal lithium accumulation on the surface of the negative electrode) during charging.

This is an irreversible conversion reaction that can lead to loss of capacity, increased short circuiting, and safety hazards as a result of structural damage caused by the lithium dendrites.

When a battery discharges in extremely low temperatures, the positive active material degrades, and metal particles accumulate because active particles rupture from the positive electrode and transition metal elements migrate to the negative electrode. This leads to lithium deposits within the battery.

How Much Capacity Is Lost When Standard Lithium Batteries Are Exposed to Cold Temperatures?

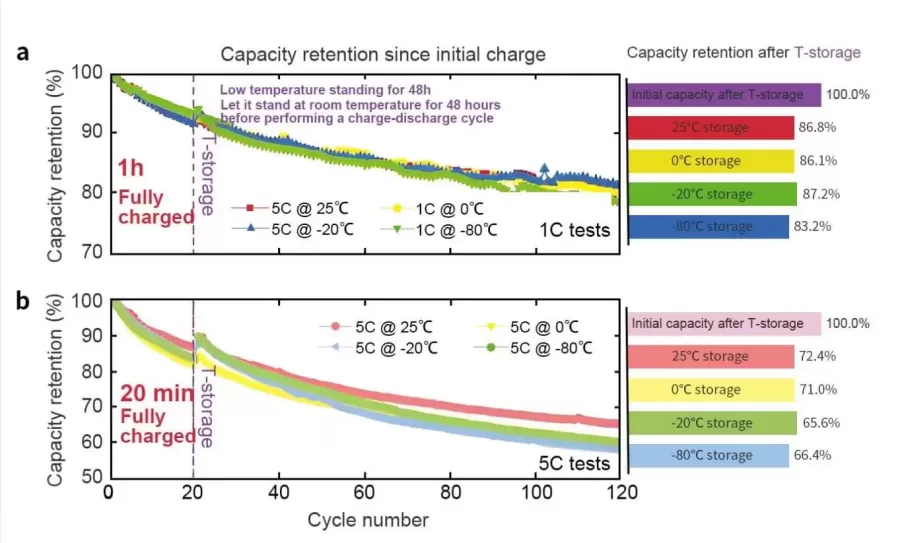

In one study, researchers proved just how much capacity can be lost when standard lithium batteries are exposed to low temperatures. In the study, researchers left batteries in cold temperatures for 48 hours, brought the batteries back up to room temperature, and then tested them for capacity loss under two settings.

Batteries that were charged and discharged at a slow/small rate lost 3.2% of their capacity, and batteries that were charged and discharged at a fast/high rate lost 6% of their battery capacity.

There are two primary causes of storage issues resulting from low-temperature exposure, as demonstrated in Figure 3:

- The rupture of the positive electrode.

- The detachment of positive electrode particles forms the binder and the resulting decrease in electrochemical activity.

In addition to storage issues, such permanent damage can lead to complete battery failure and even safety hazards such as battery explosion. That’s why experts recommend using specially designed low-temperature lithium batteries in extremely cold environments.

How are Low-Temperature Lithium Batteries Different from Standard Batteries?

While standard batteries have a recommended temperature range of -20°C to +50°C, specially designed low-temperature lithium batteries can operate safely and effectively at temperatures lower than -20°C.

These batteries share a similar structure with standard lithium batteries, but engineers modify their electrolytes and membranes to support charging, discharging, and energy storage in colder temperatures.

Why is CM Batteries people’s first choice for customized and exclusive cryogenic battery solutions?

At CM Batteries, we focus on providing high-quality and durable cryogenic batteries for a wide variety of applications. As experts in the field of custom battery packs, we go above and beyond most battery pack manufacturers to ensure that all customers receive the best possible product for their specific needs. Here are some of the ways CMB goes above and beyond:

- Genuine Quality – CM Batteries offers only top-quality products that meet international standards.

- Skilled R&D Team – CM Batteries’ expert research and development team consists of professionals with extensive knowledge of battery technology, ensuring the best product innovation and design.

- International Standards – CM Batteries follows international manufacturing standards and closely monitors every process to ensure the highest product quality.

- Reliable After-Sales Service – CM Batteries’ team of experts is available 24/7 to provide help and support for any questions or concerns that may arise.

- Custom Solutions – CM Batteries offers custom battery design services for all cryogenic battery applications to meet the specific requirements of each customer.

Learn more about our customizable low-temperature battery offerings here. Our team is ready to guide you through the design process and provide you with a product that suits your exact needs.