New battery chemistry innovations happen everyday, some of which can change the entire future of the industry as we know it. In part 1 and part 2 of this series, we discussed some of the newest battery materials that are changing lithium batteries as we know them. Here in part 3, we’ll cover even more.

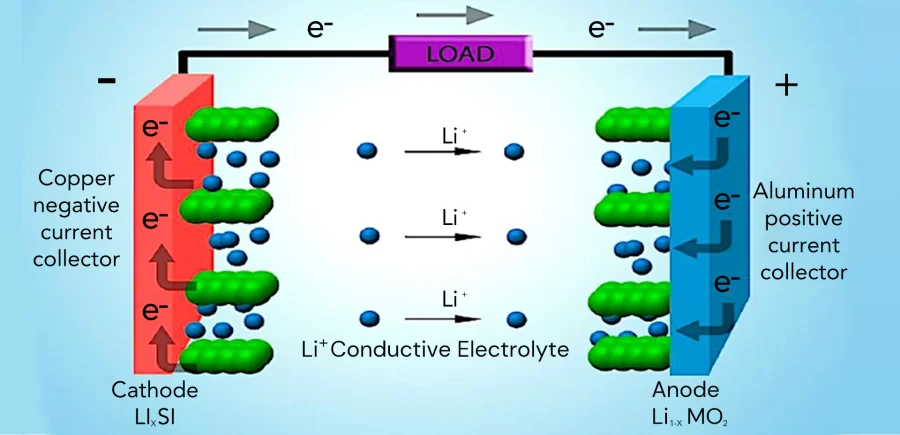

Silicon-Based Anodes

Silicon anodes have a much higher theoretical capacity than industry standard graphite anodes. The issue with silicon anodes is that during charge cycles they expand in volume. Scientists are hard at work trying to solve this issue, which may be achievable through advances in silicon nanostructures and composites. The successful implementation of silicon anodes could lead to higher energy density in the future, particularly for electric vehicles and consumer electronics.

Titanium-Based Anodes

Titanium-based anodes are safer, more stable, and have a longer lifespan than their graphite anode counterparts. Their much higher voltage reduces the risk of lithium plating, a dangerous condition where ions move too quickly from the negative electrode to the positive anode and insert themselves into the graphite particles, leaving behind a metallic layer that can lead to thermal runaway or battery fires. Titanium-based anodes also cause less lithium dendrite formation, making them a safer choice overall.

Titanium-based anodes are more resistant to structural degradation, as they’re resistant to structural changes during charge and discharge cycles. Graphite anodes expand, contract, and eventually start to crack. Titanium-based anodes are also the ideal choice for fast-charging, as they have faster lithium-ion diffusion rates that allow rapid charging without causing damage to the battery. They can also operate better at low temperatures than graphite anodes.

The main issues keeping titanium-based anodes from hitting the market in a meaningful way are energy density and high cost. Titanium-based anodes have about half the energy density of graphite anodes, and tend to be more expensive, making them an issue for high-demand functions like consumer electronics. However, they look to be a viable solution in the future for fast-charging applications like power tools, as well as for functions that require a long life cycle like industrial grid storage.

Vanadium-Based Cathodes

The use of vanadium-based cathodes is being explored due to their high capacity, conductivity, and sustainability. The excellent conductivity of Vanadium-based materials makes them a strong option for the future of rapid energy storage, such as for personal electronics and high-performance electric vehicles. Vanadium is generally abundant and cheap, as well as environmentally friendly. Harvesting Vanadium tends to be more ethical and environmentally friendly than most methods of harvesting cobalt and nickel, the current most common materials used for lithium battery cathodes.

Vanadium-based cathodes can be more expensive than nickel and cobalt, heavy, and can require a complex manufacturing process. However, it is a material that is quickly rising in popularity amongst lithium battery manufacturers due to its clear benefits.

Comparative Three Different Analysis

To provide a quick reference, here’s a comparison of the three materials:

| Material | Advantages | Challenges | Potential Applications |

| Silicon-Based Anodes | High energy density, lightweight | Volume expansion, structural integrity | EVs, consumer electronics |

| Titanium-Based Anodes | Safe, fast-charging, durable, low-temperature performance | Low energy density, high cost | Power tools, grid storage |

| Vanadium-Based Cathodes | Sustainable, high conductivity, suitable for fast energy storage | Heavy, expensive, complex manufacturing | EVs, grid storage, high-performance electronics |

Densely Functionalized Polymeric Binder

The battery materials discussed in this series represent significant strides in lithium battery innovation. Silicon-based anodes could lead to lighter, longer-lasting EVs. Titanium-based anodes might revolutionize fast-charging technologies and industrial applications, while vanadium-based cathodes could pave the way for more sustainable and ethical battery production.

These materials are still in the early stages of adoption, but with ongoing research and development, they have the potential to redefine energy storage across industries. In Part 4 we will explore even more emerging chemistries, including lithium-sulfur and solid-state batteries, that promise to address some of the key limitations of today’s lithium-ion technologies.

2 thoughts