When it comes to exporting lithium batteries or electronic products containing lithium batteries, UN 38.3 and MSDS certifications are critical. The un 38.3 and MSDS standards are relied upon across the battery and electronics industries to ensure safety and prevent accidents from production to transport and end-use. Below, we’ll break down the key differences and requirements of UN 38.3 and MSDS in clear terms.

Understanding the UN 38.3 and MSDS

What is UN 38.3?

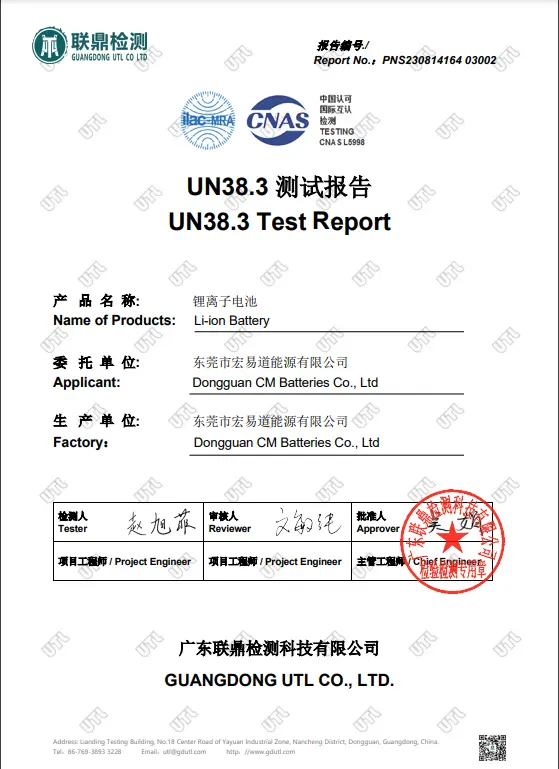

UN 38.3 specifically refers to section 38.3 of the United Nations Manual of Tests and Criteria, setting the global standard for safe lithium battery transport by air, sea, or land. This certification is indeed essential for any business looking to ship lithium batteries, whether as standalone units or incorporated into electronic products

UN 38.3 testing ensures that lithium batteries are safe for air, sea, and ground transport by simulating the stresses they may encounter. The tests include altitude simulation, thermal cycling, vibration, shock, external short circuit, impact or crush, overcharge, and forced discharge. By passing these rigorous tests, batteries are verified to handle various transport conditions, minimizing risks associated with temperature fluctuations, impact, or compression.

UN 38.3 Testing Requirements

The UN 38.3 battery certification process includes eight specific tests that simulate different conditions lithium batteries might face during transport. Each test ensures that the batteries are robust enough to withstand the challenges of real-world shipping. Here’s an overview of each test:

| Test | Purpose | Conditions | Duration | Pass Criteria |

| Altitude Simulation | Simulates air transport conditions | Low pressure (11.6 kPa) at room temperature | Minimum 6 hours | No mass loss, leakage, venting, disassembly, rupture, or fire |

| Thermal Test | Evaluates stability in extreme temperatures | -40°C to +72°C, 10 cycles between extremes | Minimum 6 hours per temp | Evaluate stability in extreme temperatures |

| Vibration Test | Simulates transport vibration | Sinusoidal waveform, 7 Hz to 200 Hz | 3 positions, 12 cycles each | No leakage, venting, disassembly, rupture, or fire |

| Shock Test | Evaluates resilience to sudden impacts | Half-sine shock pulse, 150 gn, 6 ms | Single shock per direction | No leakage, venting, disassembly, rupture, or fire |

| External Short Circuit | Tests behavior during external short circuit | 55°C, < 0.1 ohm resistance | 1 hour | Evaluate resilience to sudden impacts |

| Impact Test | Assesses mechanical durability | 15.8mm bar, 9.1 kg mass dropped from 61 cm height | Instantaneous | No disassembly or fire |

| Overcharge Test | Tests overcharge resilience for rechargeable cells | Charge at twice recommended current | 24 hours | No disassembly or fire |

| Forced Discharge | Forces discharge beyond capacity | Applies to primary and secondary cells | 24 hours | Charge at twice the recommended current |

What is MSDS?

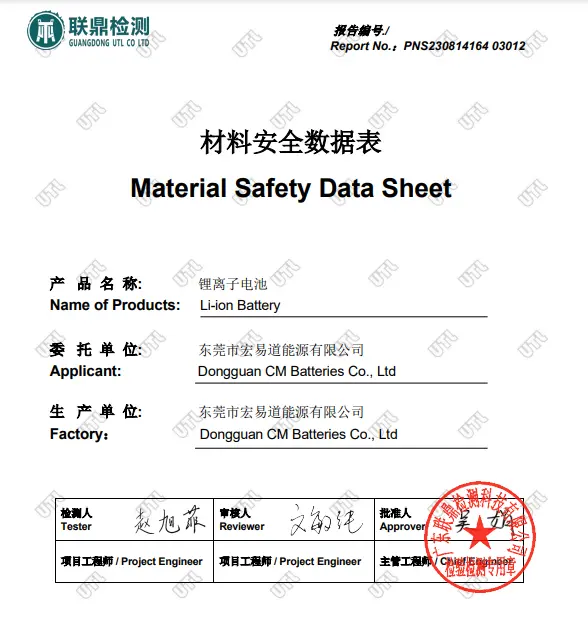

An MSDS or SDS for lithium batteries provides essential information that helps users, transporters, and emergency responders understand how to manage the battery safely. It outlines potential hazards, including risks of fire, chemical exposure, and environmental impact, and gives detailed guidelines on proper storage and handling practices to prevent incidents.

Here’s a table summarizing the 16 critical sections of an MSDS:

| Section | Description |

| Product and Company Identification | Product name, type, manufacturer details, emergency contact info, recommended use, restrictions |

| Hazards Identification | Hazard classification, signal words, hazard statements, precautionary statements, pictograms |

| Composition/Information on Ingredients | Chemical composition, component percentages, CAS numbers, trade secret claims |

| First Aid Measures | Emergency procedures for exposures, immediate medical needs, specific treatments, symptoms |

| Fire Fighting Measures | Suitable extinguishing media, special hazards, protective equipment, firefighting procedures |

| Accidental Release Measures | Personal precautions, environmental precautions, containment, and clean-up procedures |

| Handling and Storage | Safe handling, storage conditions, incompatible materials, specific end uses |

| Exposure Controls/Personal Protection | Exposure limits, engineering controls, personal protective equipment, monitoring methods |

| Physical and Chemical Properties | Appearance, color, odor, pH, melting/freezing point, boiling point, flash point, evaporation rate |

| Stability and Reactivity | Chemical stability, hazardous reactions, conditions to avoid, incompatible materials, decomposition |

| Toxicological Information | Routes of exposure, acute/chronic effects, carcinogenicity, reproductive toxicity |

| Ecological Information | Environmental impact, biodegradability, bioaccumulation, mobility in soil |

| Disposal Considerations | Waste treatment, regional regulations, special precautions, disposal practices |

| Transport Information | UN number, proper shipping name, hazard class, packing group, environmental hazards |

| Regulatory Information | Safety and environmental regulations, specific regulations, chemical safety assessment |

| Other Information | Revision date, literature references, training advice, further information |

UN 38.3 and MSDS (or SDS) both prioritize the safe handling, storage, and transport of lithium batteries, but they serve different functions in achieving these goals:

Safety Focus

- UN 38.3 prioritizes the safe transportation of lithium batteries, avoiding any dangers during transit.

- MSDS focuses on workplace safety by focusing on handling and emergency response protocols for various hazardous materials.

Regulatory Compliance

- UN38.3 is required by international transportation regulations, particularly for lithium batteries.

- MSDS is mandated by occupational safety regulations like OSHA and GHS to ensure the safe handling and storage of hazardous materials.

Hazard Identification

- UN 38.3 identifies potential transport-related hazards for lithium batteries and requires tests to address them.

- MSDS outlines hazards in handling, storage, and use of hazardous materials, guiding safe usage practices.

Standardization

- Both UN 38.3 and MSDS follow standardized procedures, promoting consistent safety practices across industries and regions.

Risk Mitigation

- UN 38.3 minimizes transport risks through rigorous testing to ensure batteries endure transit conditions safely.

- MSDS mitigates workplace risks by providing detailed safety instructions and handling guidelines.

Documentation

- UN 38.3 requires official test reports and certification to confirm transport safety.

- MSDS involves comprehensive safety documentation for each material, including handling instructions and hazard data.

International Acceptance

- UN 38.3 is recognized by global transport authorities.

- MSDS is accepted internationally, especially with GHS standards ensuring uniform safety information worldwide.

What are the Key Differences Between UN 38.3 and MSDS?

| Key Differences | UN 38.3 | MSDS |

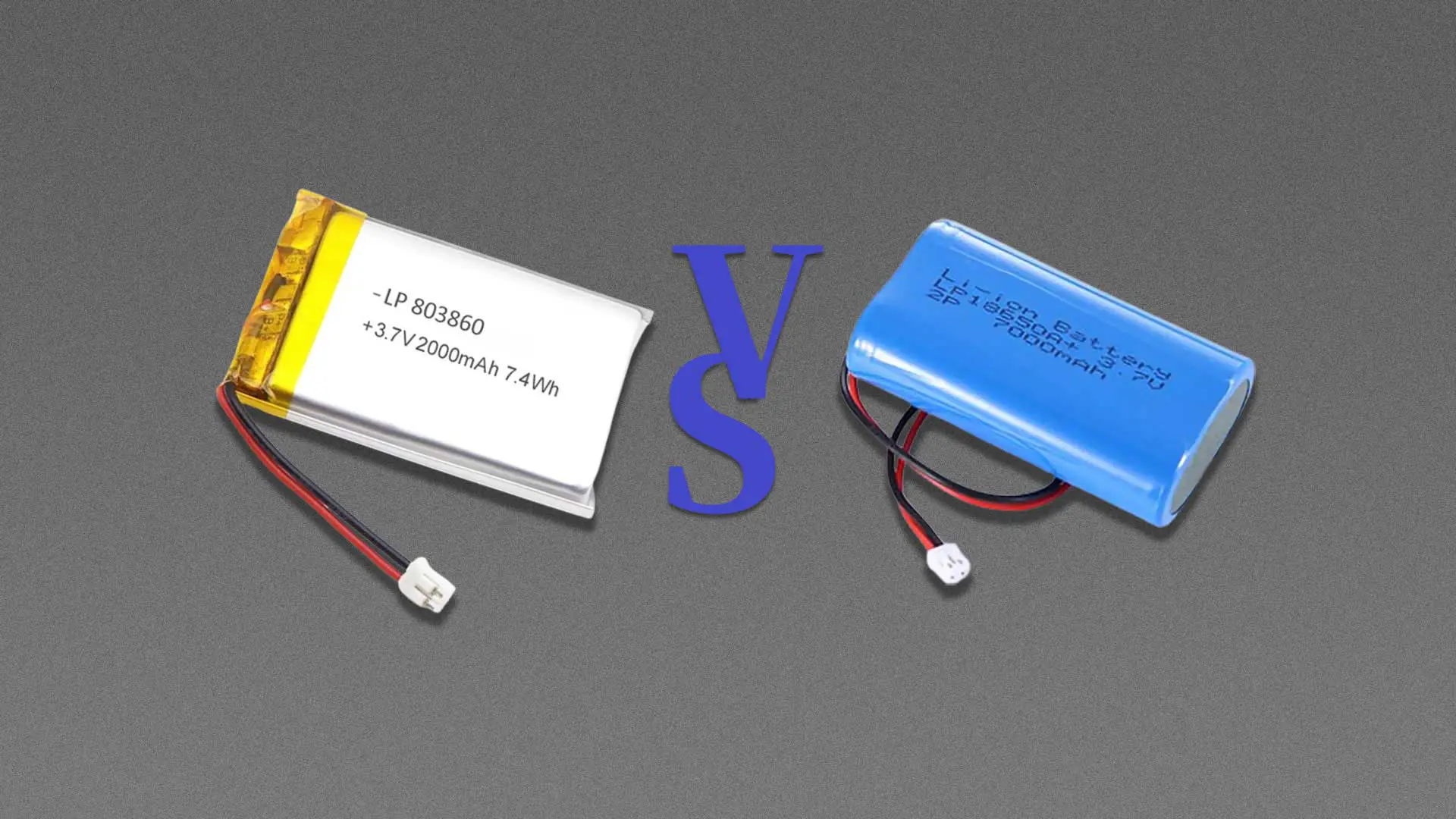

| Purpose and Scope | Ensures the safe transport of lithium batteries by setting specific test requirements to prevent risks such as fire, explosion, or leakage during transit. Specifically applies to lithium battery transport safety. | Provides detailed safety information for various materials, especially chemicals, to ensure safe handling, storage, and emergency response in the workplace. Covers a broad range of products, not limited to transport requirements. |

| Provided Content and Information | Includes results from a series of controlled tests, such as altitude simulation, high-low temperature cycling, vibration, impact, external short circuit, overcharge, and forced discharge, all of which evaluate battery safety during transport. | Provides comprehensive safety documentation, covering product identification, physical and chemical parameters, health hazards, storage and leak disposal guidance, first-aid measures, and regulatory information. No testing is required, based on existing data. |

| Testing Protocol | Requires multiple tests (T1-T8) to simulate various transport conditions, including temperature extremes (72±2°C to -40±2°C with ≥6h storage), impact, vibration, and other stress tests, ensuring battery safety over a minimum of one week of testing. | Does not require testing but focuses on chemical composition and safety information, providing guidelines for safe use, handling, and storage without physical testing. |

| Regulatory Environment and Compliance | Compliance with international transport regulations, such as IATA standards, requires manufacturers to obtain a UN 38.3 test report before shipping batteries. Airlines and airport cargo departments review these documents to verify compliance. | Compliance with occupational safety regulations (e.g., OSHA in the U.S. and GHS internationally). Requires manufacturers and importers to create and distribute MSDSs, with employers ensuring workplace accessibility and employee training on MSDS contents. |

| Compliance Responsibilities | Manufacturers: Ensure UN 38.3 compliance and testing before shipment; Shippers: Verify battery certification; Logistics Providers: Ensure safe handling and compliance to avoid penalties. | Manufacturers: Create and distribute MSDSs; Importers: Ensure MSDS availability in compliance with local regulations; Employers: Store and make MSDS accessible for all hazardous materials on-site and train employees on usage. |

| Certification and Documentation Requirements | Requires a third-party battery certification test report (UN 38.3) to verify batteries have passed all necessary safety tests. | Provides a safety manual with detailed guidelines on handling, storage, and emergency responses. While it can be created by the manufacturer, MSDS quality reflects company standards and should accompany products sold, transported, or exported. |

| Issuing Authority | Must be issued by a qualified third-party testing company to verify transport safety compliance, with reports reviewed by airline and aviation regulatory authorities. | May be issued either by a third party or by the factory itself. Typically provides reference information based on chemical composition for the safe handling and storage of materials, without requiring testing, as a broad safety document. |

| International Acceptance | Recognized by global transport authorities as a critical standard for the safe transit of lithium batteries. | Widely accepted internationally, especially with GHS standards, which ensure consistency across global markets, covering chemicals and hazardous materials broadly. |

When Does a Lithium-ion Battery Require UN 38.3 Certification and MSDS?

UN 38.3 Battery Test Report

- New Battery Designs

For existing battery models, significant design changes—like modifications to the casing, chemistry, or structural components—can alter the battery’s behavior under stress, so re-certification is needed to confirm continued safety compliance.

- International Transport

UN 38.3 certification is required for air shipments and mandatory for sea freight. Depending on the restrictions, cross-border ground transportation may also require this certification.

- Commercial Distribution

UN 38.3 certification is essential for lithium batteries across various sectors, whether they’re part of consumer retail products, used in industrial machinery, or integrated into OEM supply chains. This certification verifies that batteries are safe for transport and handling, a critical step before they can legally enter the marketplace.

Lithium-ion Battery MSDS

- Product Manufacturing

MSDS documentation is crucial in production, serving both as a safety measure and a tool for quality control.

- Commercial Distribution

An MSDS is essential product paperwork for commercial distribution, providing safety information to both distributors and customers.

- Workplace Guideline

Employers are responsible for providing MSDS documentation to ensure employees are well-informed about the safe handling, storage, and emergency procedures related to hazardous materials, including lithium batteries. MSDS sheets serve multiple critical functions in the workplace.

Understanding Your Lithium Battery Certification Timeline

UN 38.3 Certification Timeline

| Phase | Duration | Key Activities | Notes |

| Preparation | 2-4 weeks | Lab report preparation results reviewCertificate issuanceFinal documentation | Critical foundation phase – don’t rush |

| Testing | 4-8 weeks | Altitude simulation Thermal testingVibration testingShock testing External short circuit Impact testingOvercharge testing Forced discharge | Longest phase; sequential testing required |

| Documentation | 1-2 weeks | The final phase before certification | Lab report preparation results review certificate issuanceFinal documentation |

| Total UN 38.3 | 7-14 weeks | Allow buffer time for unexpected issues |

MSDS Development Timeline

| Phase | Duration | Key Activities | Notes |

| Information Collection | 1-2 weeks | Safety expert review legal compliance check management approval document filing | Critical foundation phase – don’t rush |

| Document Creation | 1-2 weeks | Writing 16 MSDS sectionsTechnical review translations if needed regional formatting | Core documentation phase |

| Review & Finalization | 1-2 weeks | Safety experts review legal compliance check management approval document filing | Final verification phase |

| Total MSDS | 3-6 weeks | Can run parallel with UN 38.3 |

The Impact of UN 38.3 and MSDS on Lithium Battery Manufacturers and Consumers

For Lithium Battery Manufacturers:

UN 38.3 Testing: By adhering to UN 38.3 regulations, producers may ensure that their batteries are safe to transport, reducing the chance of incidents and responsibility. This compliance also allows for smooth international shipment, which increases market reach and commercial potential.

MSDS Implementation: Providing MSDSs contributes to the safe handling of products across the supply chain, reducing workplace accidents and health hazards. This builds a reputation for safety and responsibility while lowering liability.

Consumer Trust: Manufacturers who adhere to these criteria earn the trust of their customers, who rely on the product’s safety and reliability. This trust boosts brand reputation and customer loyalty.

For Consumers:

Product Safety: UN 38.3 compliance ensures that consumers receive thoroughly tested batteries, reducing the chance of malfunctions and accidents. MSDS compliance provides access to specific safety information, allowing customers to handle items properly.

Informed Decisions: MSDSs offer customers important product information for safe use, handling, and disposal. This knowledge enables more informed decisions, which enhances overall consumer safety and environmental protection.

As a custom battery pack manufacturer, CM Batteries strives to support our customers obtain the necessary certifications to ensure safe and compatible battery solutions. We supply all relevant testing and paperwork, such as UN 38.3 test reports for transportation safety and MSDS for workplace safety. Our guide, “Battery Certifications: A Comprehensive Guide to Lithium-Ion Battery Pack Certificates,” provides detailed information on these certificates and how CM Batteries assists customers in obtaining the certifications required for their specific applications, thereby simplifying compliance and streamlining certification for all custom battery pack needs.