No matter how we achieve human development, we should protect the environment. It is essential to explore eco-friendly solutions in every industry. Some famous brand companies go sustainable and help save biodiversity. At CM Batteries, we are not only chasing profit but also protecting Mother Earth with our actions. Let the environment guide our development and battery production by choosing the eco materials and controlling production pollution. As a professional supplier of customized lithium battery packs, I would like to introduce you to an environmentally friendly packaging solution for battery packs – PVC heat shrink tubing.

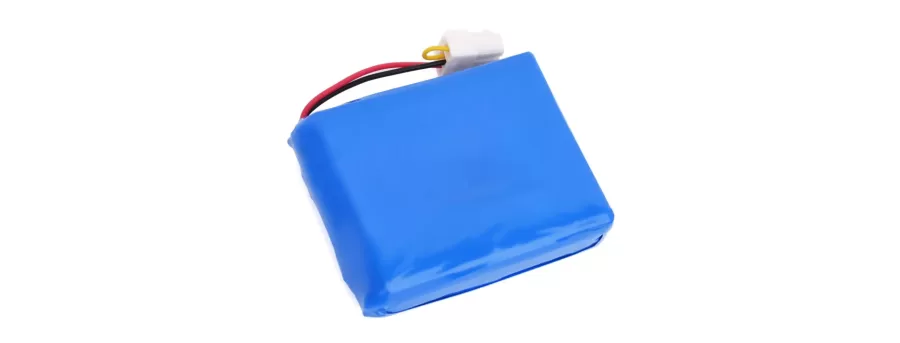

What Is The PVC Heat Shrink Wrap Of The Battery Pack?

PVC heat shrinkable tubing, also known as polyvinyl chloride tubing film, is made of PVC (polyvinyl chloride) resin powder, with pigments, plastic plasticizers, and other auxiliaries, high-speed kneading, extrusion, positive pressure expansion, cooling, and molding, which makes use of the “memory reduction” effect of plastics, to achieve the effect of heat shrinkage.

- Environmentally friendly alternatives to battery film production.

- A thin-walled, low-cost material with excellent electrical and mechanical properties.

- When exposed to temperatures over 98 degrees for a few seconds, the specially formulated polyvinyl chloride material shrinks rapidly and conforms uniformly to the shape of the object being covered.

- Good electrical performance: insulation, moisture-proof, corrosion-proof, dust-proof.

Why PVC Heat Shrink Tubing Is An Environmentally Friendly Battery Pack Packaging Solution?

The properties of PVC heat shrink tubing make it ideal for packaging battery packs in this application. The material is flexible and durable, allowing the packs to be customized to the specific needs of the customer, ensuring that the battery packs are fully protected during transportation and use. This reduces the risk of damage and extends the life of the battery.

Furthermore, the use of PVC heat shrink tubing can significantly reduce production costs and improve efficiency. Its easy installation process eliminates the need for excessive labor and equipment, resulting in cost savings for manufacturers. The durability of PVC heat shrink tubing minimizes the likelihood of product defects, reducing waste and increasing overall productivity.

Beyond the benefits to manufacturers and consumers, PVC heat shrink tubing has several positive environmental impacts. Traditional methods of battery film production involve the use of non-recyclable materials that contribute to waste and pollution. PVC heat shrink tubing, on the other hand, can be recycled, reducing the amount of waste that ends up in landfills.

CMB’s “Charge Less” Program

As a lithium battery pack manufacturing company, we understand that it is critical to encourage further research and exploration into the use of eco-friendly materials in battery production. This guides us to develop environmentally friendly battery technology and choose environmentally friendly batteries.

That’s why we created the “Charge Less” program, where we offer a 50% discount on custom battery packs to support organizations, projects, or institutions working on research and development of solutions to the climate crisis, including the further development and use of drones to study the state of the environment and wildlife populations.

In summary, the benefits of using battery shrink wrap 18650 in 18650 battery pack production are substantial. It not only reduces costs and improves efficiency but also has a positive impact on the environment. By minimizing waste and pollution, CM Batteries are moving in a sustainable and responsible action. Contact CM Batteries now!

One thought