Thermal runaway is a critical concern in battery technology, especially in lithium-ion batteries commonly used in various applications from consumer electronics to electric vehicles. Understanding the risks associated with thermal runaway is essential for ensuring safety and mitigating potential hazards. That’s why we’re going to take a closer look at the risk of thermal runaway in batteries.

What is Lithium Battery Thermal Runaway?

Definition and Chain Reaction Process

Lithium-ion thermal runaway is a complex chain reaction phenomenon with potentially catastrophic consequences. Lithium thermal runaway often begins with the breakdown of the Solid Electrolyte Interphase (SEI) membrane within the negative electrode of the battery cell. This breakdown can be initiated by factors such as overcharging, physical damage, or manufacturing defects.

Initial Breakdown Phase

Once the SEI membrane breaks down, the separator within the battery cell begins to decompose and melt. This breakdown compromises the structural integrity of the cell and facilitates the spread of reactions between the electrode and electrolyte. As the negative electrode interacts with the electrolyte, it triggers further decomposition reactions, leading to the release of heat and gases.

Escalation and Spread

This process can escalate rapidly and spread to the positive electrode, exacerbating the thermal runaway phenomenon. The widespread decomposition and breakdown within the battery cell can result in internal short circuits, causing localized heating and further accelerating the chain reaction. Eventually, the electrolyte ignites, leading to intense combustion and the emission of heat and harmful gases.

Energy Release Perspective

People envision lithium batteries as enclosed energy spheres. These small batteries exist as reducing agents and oxidizing agents, enabling them to undergo either slow charging and discharging or vigorous combustion.

Thermal runaway lithium-ion battery denotes a chain reaction triggered by various factors, generating heat that raises the lithium-ion battery thermal runaway temperature to over a thousand degrees Celsius, igniting lithium batteries intensely and emitting a significant amount of heat and harmful gases in a short period.

Magnitude of Energy Release

Hence, when lithium-ion batteries experience thermal runaway, the energy released by the entire battery pack is staggering. A battery pack consisting of 100 cells with a charge capacity of 100Ah has a runaway energy of 240,000,000J, which is about 57 kilograms of TNT. Although scientists and engineers, continue to improve the design, enhance the algorithm, and then effectively improve the safety of automotive lithium-ion battery packs, in real life we will hear from time to time some electric cars, cell phones burst into flames.

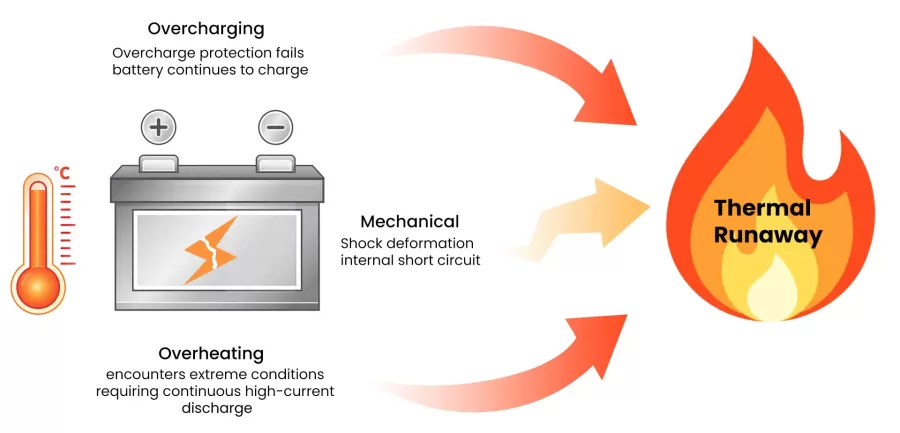

What Causes Thermal Runaway in Batteries?

- Overcharging: The battery itself has overcharge protection, but if this overcharge protection malfunctions and the battery continues to charge, it will lead to overcharging, triggering thermal runaway. As the battery is used over time, aging becomes more severe, and the consistency of the battery pack deteriorates. At this point, if the battery is overcharged, it is highly susceptible to thermal safety issues. Therefore, it is essential to always follow the instructions for safe charging.

- Overheating: When the battery undergoes high-speed discharge or encounters extreme conditions, the internal temperature of the battery gradually rises. When a significant amount of heat accumulates in the battery, failure to promptly limit the discharge current may result in thermal runaway of the lithium battery.

- Mechanical: Impact, internal short circuits, and other actions that damage the battery pack can cause thermal runaway.

The process of lithium battery thermal runaway occurrence

Overview of Thermal Runaway Stages

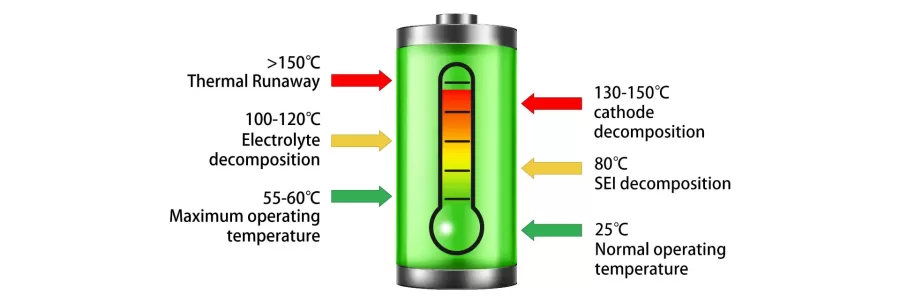

Thermal runaway is divided into three stages: the self-heating stage (50°C-140°C), the runaway stage (140°C-850°C), and the termination stage (850°C-room temperature). Some literature indicates that the massive melting temperature of the separator begins at around 140°C.

Self-Heating Stage (50°C-140°C)

The self-heating stage, also known as the heat accumulation stage, begins with the dissolution of the SEI membrane. The dissolution of the SEI membrane becomes noticeable when the temperature reaches around 90°C. The dissolution of the SEI membrane exposes the negative electrode and the lithium-inserted carbon components within the negative electrode to the electrolyte, triggering an exothermic reaction, thus raising the temperature. The temperature increase, in contrast, accelerates the further decomposition of the SEI membrane. If there is no external cooling mechanism, this process will continue until the SEI membrane is completely decomposed.

Runaway Stage (140°C-850°C)

During the runaway stage, temperatures above 140°C trigger electrochemical reactions in electrode materials. The increased mass of reactants accelerates temperature rise. Observable changes include a sharp voltage drop. The separator begins to melt massively at this temperature range. This results in direct electrode contact, causing widespread short circuits.

Intense Reaction Phase

Within a short period, intense reactions generate large amounts of gas and heat. The heat further heats the gas, which expands and ruptures the battery cell casing, resulting in phenomena such as material ejection. The runaway reaches its most intense state, with the highest temperature reached during this stage.

Thermal Propagation

If there are other battery cells nearby, thermal runaway may spread to them by transferring heat to the surroundings. Heat may conduct to conductive parts or volume expansion. Battery cells that were originally spaced apart may now be in direct contact, facilitating heat transfer between cell casings.

Termination Stage (850°C-Room Temperature)

In the termination stage, once thermal runaway occurs, it can only be terminated when all reactants are consumed. A report from the fire department indicates that for enclosed devices containing high-energy substances like lithium batteries, firefighting methods cannot immediately stop ongoing thermal runaway.

Fire extinguishing agents cannot effectively reach the reacting substances. Firefighters face high risks in such situations, with limited measures available. Generally, the approach is to isolate the accident site. Thermal runaway can only naturally terminate once the reactants are consumed.

How to Prevent Li-ion Thermal Runaway?

As we can see from above, the emphasis on thermal runaway lies in prevention and monitoring. Once thermal runaway occurs, there is little to be done to stop it, much like trying to extinguish a hand grenade explosion.

Prevention

1. The key to thermal runaway lies in the stability of the positive and negative electrode materials and the electrolyte. In the future, higher breakthroughs are necessary in several key areas. These include coating and modification of positive electrode materials. Homogeneous electrolyte compatibility with electrodes needs improvement. Electric core thermal conductivity also requires enhancement. Or choose the electrolyte with high safety to play the effect of flame retardant.

2. Implementing system upgrades and improvements from an external perspective.

- PTC (Positive Temperature Coefficient) devices: Installing PTC devices in lithium-ion batteries considers both internal pressure and temperature. When the battery temperature rises due to overcharging, the internal resistance of the battery quickly increases to limit the current, thereby reducing the voltage between the positive and negative electrodes to a safe level, achieving automatic protection for the battery.

- Explosion-proof valves: When the battery experiences abnormal internal pressure, the explosion-proof valve deforms, cutting off the lead wire inside the battery used for connection, thereby stopping charging.

- Enhanced cooling methods: The thermal management system is crucial for controlling temperature and ensuring that the battery operates at a reasonable temperature. Typically, the vehicle controller controls the thermal management system. When battery pack temperatures become abnormal, the air conditioning system provides timely cooling or heating to ensure battery safety and longevity.

- Aerogel battery thermal insulation pads: Manufacturers assemble aerogel thermal pads between power battery cells and modules. When thermal runaway occurs in a battery cell, the aerogel’s low thermal conductivity provides thermal insulation that delays or blocks the accident. When a battery cell overheats and burns, the aerogel thermal pads achieve Class A non-combustible performance to effectively block or slow fire spread. This design ensures that the battery pack will not burn or explode within 5 minutes, providing sufficient escape time.

Engineered for thermal stability, CMB batteries maintain a 1C discharge rate even at temperatures as high as 85°C, thanks to innovative design and high-temperature electrolytes ensuring longevity and performance. CMB provides professional high temperature battery pack solutions for medical equipment, oil exploration, and IoT, reducing the probability of thermal runaway to 0.01%.

Monitoring

1. Early and mid-stage monitoring

- Real-time Thermal Runaway Early Warning Technology Monitored by BMS

Currently, the most easily achievable solution is to use BMS to monitor temperature, voltage, and other operating parameters to detect the early signs of thermal runaway. To improve fault detection capabilities, engineers can use or develop higher precision and reliability temperature sensors and voltage sensors. At the same time, developers can construct more accurate and effective state parameter estimation models through algorithms to detect misuse and anomalies earlier. Artificial intelligence can play a certain role in this process. However, there are also problems with BMS solutions: external parameter monitoring cannot provide complete and accurate simulation, nor can it accurately reflect internal electrochemical changes, making modern BMS unable to comprehensively assess the potential thermal runaway risk of battery cells.

- Thermal Runaway Early Warning Technology Based on Internal State Prediction

External control is difficult to achieve fully. Researchers are therefore starting from the inside. Current research focuses on real-time detection of internal battery temperature and impedance. Methods include embedded foldable Bragg fiber optic sensors or electrochemical impedance analyzer frequency response analysis. These approaches remain in the laboratory stage due to cost and technical constraints.

- Early Warning Technology for Thermal Runaway Based on Gas Detection

In the early stage of lithium-ion battery thermal runaway, characteristic identification parameters change very slowly. These parameters include battery temperature, discharge voltage, and discharge current. Normal BMS cannot detect battery faults early due to these gradual changes. At this time, a large amount of gas will be produced due to the internal electrochemical reactions of the battery. Therefore, using gas detection sensors to achieve early warning of lithium-ion battery thermal runaway is feasible. Currently, some companies have developed relevant products combining gas detection with fire protection.

2. Late-stage Monitoring

The battery cell separator begins to dissolve massively. This leads to widespread internal short circuits within the battery. Voltage plummeting then occurs due to the massive short circuits between the positive and negative electrodes. At this point, thermal runaway is completely uncontrollable.

A detectable electrical parameter, battery cell terminal voltage, appears during this process. Current BMS systems can only accurately collect voltage data for each series module (each module containing several cells connected in parallel). This phenomenon allows the management system to detect a fault in the battery cell.

However, voltage drop is detected over time, it is already an irreversible moment of thermal runaway. The triggering signal for cooling measures loses its significance.

What we can do is consider strategies to delay the spread of thermal runaway during the product design and implementation process. In reality, thermal runaway occurs extremely rapidly and can cause devastating damage within a short period. Therefore, it is essential to delay or suppress the hazards of thermal runaway to provide sufficient time for escape after an accident occurs.

CMB engineers have studied the thermal runaway of lithium battery packs for decades. We can design BMS for different applications, monitor the temperature, discharge voltage, and discharge current of the battery, stop the battery, and sound an alarm before thermal runaway. If you are looking for a 100% safe lithium battery pack for your device, click here to get help from CMB engineers!

Conclusion

Once thermal runaway occurs in a lithium battery pack, it is like a shot arrow that cannot be retrieved. Currently, the industry has roughly understood the mechanisms behind thermal runaway. Future research will focus more on battery safety, thermal management, early prediction and warning of thermal runaway, and impediments to late-stage notification and communication. With continuous exploration by industry experts, it’s believed that comprehensive solutions to battery thermal runaway will be achieved shortly. At that time, people could drive electric vehicles with greater peace of mind and use energy storage products on a large scale, enjoying a new lifestyle powered by clean energy with confidence.

4 thoughts