The energy storage market is undergoing a quiet revolution as sodium-ion batteries transition from research labs to commercial reality. Unlike their lithium counterparts, these batteries leverage one of Earth’s most abundant resources—sodium—offering both opportunities and challenges for manufacturers. Now, I will introduce sodium battery technology, the working principle of sodium-ion battery, explore its advantages and disadvantages, and highlight key limitations that still need solutions.

What is Sodium-ion Battery Technology?

Sodium-ion batteries represent a promising class of rechargeable energy storage systems that operate through sodium ion movement between electrodes. These batteries mirror lithium-ion technology in basic architecture but utilize sodium’s natural abundance instead. Sodium battery’s core components include electrodes, separator, current collectors, and electrolyte – divided into active materials (electrode substances and electrolytes that store energy) and inactive structural elements (separators, binders, and conductive additives).

Cathode Materials

- Layered Oxides (e.g., NaNiCoMnO₂)

Pros: Using layered oxides as battery anodes would enable sodium-ion batteries to have energy densities similar to LiFePO4 (around 200 Wh/kg), which is considered fantastic.

Cons: Manufacturers should take the sodium content under precise control; sodium battery-relevant synthesis conditions are relatively strict

- Prussian Blue Analogs (e.g. Na₂Fe[Fe(CN)₆])

Pros: Prussian blue is a cheap material, and the sodium-ion battery structure made from it is not prone to decay, making it suitable for grid storage.

Cons: Sodium-ion batteries made with Prussian blue have a low initial efficiency (about 87%) due to irreversible sodium capture.

- Polyanion Compounds (e.g. NaFePO₄)

Pros: Sodium batteries made from polyanionic compounds have an excellent cycle life (over 6,000 cycles) and are suitable for long-term storage.

Cons: Taking polyanionic compounds as cathode material, this sodium battery’s energy density is only moderate (about 160 Wh/kg).

Anode Materials

- Hard Carbon

Pros: The reason why most manufacturers tend to select hard carbon as anode material is that the sodium battery made of it has high capacity (about 300 mAh/g), 40% cheaper than lithium-ion graphite.

Cons: Hard carbon’s voltage curve fluctuates greatly, making it complicated to monitor the sodium ion battery charging state.

- Titanium-Based Materials

Pros: Utilizing a titanium-based material, the sodium battery has an ultra-long lifespan (over 10,000 cycles) and excellent low-temperature performance.

Cons: In a low-voltage environment (about 0.3V), the energy density of sodium-ion batteries will decrease.

How Do Sodium Batteries Work?

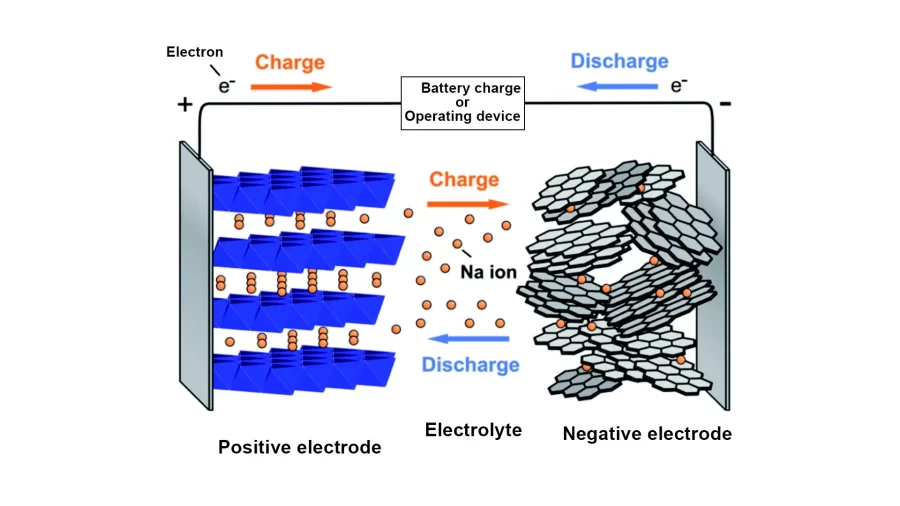

Sodium-ion battery working principle is similarly to lithium-ion battery. When charging, sodium ions leave the positive electrode and move to the negative electrode through the electrolyte, while electrons flow through the external circuit. During discharge, this process reverses. This ion movement allows sodium battery to store energy effectively while offering cost advantages over lithium batteries, since sodium is more abundant and cheaper.

Sodium Battery Technology Development

Sodium battery technology traces its origins to 1967 with early sodium-sulfur systems. Progress stalled after 1979 when graphite anodes—ideal for lithium batteries—proved ineffective for sodium storage, despite the promising “rocking chair” battery concept introduced by French researchers.

The breakthrough came in 2000, when Canadian scientists demonstrated that hard carbon anodes could reversibly store sodium, reigniting research interest. By 2010, as lithium battery technology matured and supply concerns grew, sodium batteries entered commercial exploration, with startups worldwide testing potential applications.

The landscape shifted dramatically in July 2021, when CATL unveiled its sodium-ion battery, targeting full-scale production by 2023. Soaring lithium prices in 2022 further accelerated industry adoption. On April 21, 2025, CATL achieved another milestone by launching the world’s first mass-produced sodium battery—the CATL Sodium New—transitioning the technology from niche applications to broad commercialization and reshaping global energy infrastructure.

Sodium-Ion Batteries: Pros & Cons

Advantages of Sodium-ion Battery

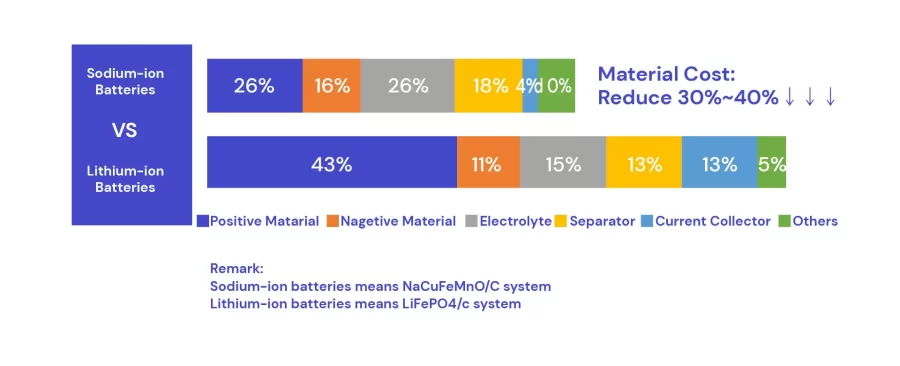

Lower Costs

- The material costs of sodium batteries are 32% of lithium-ion batteries. Therefore, sodium-ion battery costs are 45% lower than LiFePO4 battery if you want to take mass production. The sodium’s price is cheaper, as it’s 400 times more plentiful in nature, enabling potential 50% system savings.

Superior Low-Temperature Performance

- Unlike lithium batteries (which struggle to operate below -20°C), sodium batteries can still maintain 85% of their capacity at -30°C. CATL sodium-ion batteries can even maintain 80% of their capacity at -40°C.

- Sodium ions have less resistance to migration in electrolytes and are naturally suitable for cold resistance. In typical high-altitude cold regions, a 200-megawatt sodium-ion battery wind farm in Inner Mongolia Autonomous Region, which reduces costs to $0.035 per kilowatt-hour, is 37% cheaper than lithium batteries.

Ultra-Fast Charging

- Sodium battery charges 90% in just 12 minutes, a tech expert at China Southern Power Grid, Li Yongqi, said.

- HiNa Battery’s sodium-ion battery technology is adapted to the 800V to achieve fast charging, with an efficiency of 95% at a 5C rate. An electric car can charge for 10 minutes and have a range of 200 kilometers

Eco-Friendly

- Sodium-ion batteries have clear environmental merits. Sodium is abundant and available worldwide, and its production emits less carbon dioxide, making it a cleaner alternative for energy storage.

Sodium-Ion Battery Disadvantages

Heavier & Bulkier

- Sodium atoms are larger, leading to higher weight and volume.

- Sodium ions have a large size and are not suitable for compact devices (e.g., smartphones, wearables).

Lower Energy Density

- Sodium-ion batteries have an energy density of only 100-150 Wh/kg. LiFePO4 batteries’ energy density is 200 Wh/kg, and NMC batteries’ energy density is 250 Wh/kg

- Sodium batteries have limited use in electric cars or laptops because of space and weight limitations. However, LiFePO4 batteries are better suited for these applications.

Shorter Lifespan & Stability

- Sodium-ion batteries have fewer charge cycles than lithium batteries. Sodium-ion batteries have 1,500-2,000 cycles, while LiFePO4 has 2,000-3,000 cycles.

- Sodium batteries are not yet feasible for high-end applications that require long life.

Although sodium-ion batteries have attracted attention in recent years, their poor energy density, insufficient technological maturity still restrict their applications. In contrast, CMB recommends customized lithium-ion battery solutions, which feature highr energy density, extended lifespan, custom voltage, and current design. We ensure every battery is precision-engineered to match your product’s performance. And meet your environmental demands, delivering more efficient and reliable system integration.

Are There Any Commercial Sodium-ion Batteries?

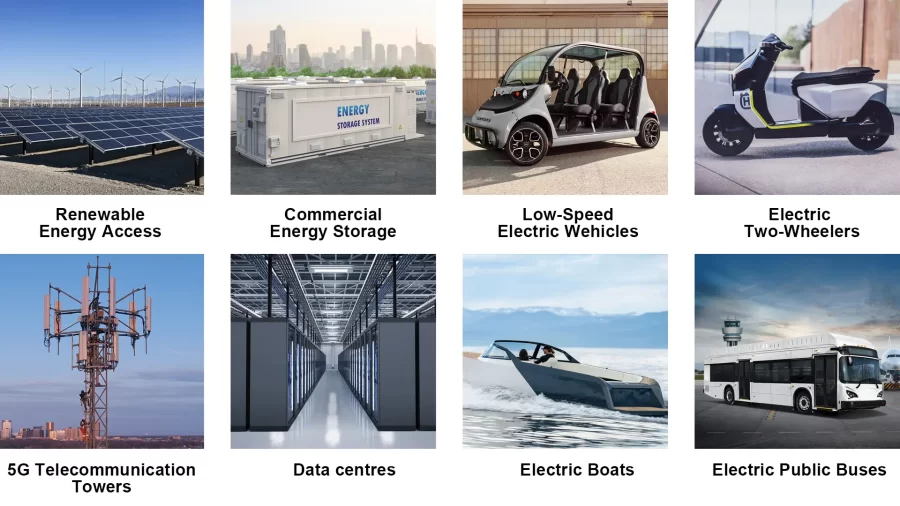

Sodium-ion batteries are now emerging in niche markets, with applications ranging from telecom tower backup power to cold-region EVs and microgrid storage projects. I have listed some of the hottest applications of sodium-ion battery technology in the past two years. Let’s take a look.

1. Telecom Tower Energy Storage

Leading sodium battery manufacturer offers high-density batteries for telecom applications in extreme climates.

- Sodium battery has a discharge rate of up to 90% at -40°C, but lead-acid batteries is out of control under this environment.

- Sodium-ion batteries maintain a stable 1C rate performance in the temperature range of -40°C to 60°C.

Example: Shuangdeng’s evolution of metal-based solutions demonstrates why sodium batteries are becoming the preferred alternative to lithium batteries for remote towers, featuring -30°C charging capability and smart remote monitoring.

2. Cold-Climate Electric Vehicles

Thanks to the unique electrolyte properties, sodium-ion batteries are now widely used in light EVs, e-bikes, trikes, and low-speed electric vehicles in cold climates:

- At -30°C, sodium-ion battery capacity retention exceeds 85% (outperforms lithium batteries)

- The total cost of sodium-ion batteries is lower than that of lead-acid batteries

- The sodium-ion battery price is competitive

Example: Zenergy and Aima collaborate on cold-weather e-bikes using sodium batteries.

3. Distributed Energy Storage

Sodium ions play a critical role in keeping homes/small businesses safe during harsh winters:

- Sodium ions can store cheap off-peak or renewable energy

- Sodium batteries cost 40% less than lithium batteries in cold climates

- Sodium battery operates reliably at -40°C

Example: In China’s Guangxi Province, a 10 MWh sodium battery plant has powered 3,500 households for 10 months, which makes 7.3 million kWh of clean energy each year.

When Will Sodium Batteries Be Mass-Produced?

At present, sodium battery technology is mainly used in some energy storage, base stations, low-speed vehicles, and other markets. Although sodium batteries have achieved small-scale production in specific fields, they still face many challenges on the road to large-scale commercialization. For instance, sodium battery manufacturers need to improve battery performance, reduce production costs, and improve the industrial chain capacity. Additionally, the entire battery industry should strive together to stabilize the supply of raw materials, optimize sodium battery technology, and improve the market’s acceptance of sodium-ion batteries. Sodium batteries are limited due to their large size and low energy compared to lithium-ion batteries. There is still a promising future for sodium-ion battery applications in some specific fields.

Sodium-Ion Battery Technology Prospects

While sodium-ion batteries are gaining traction in these niche markets, their limitations in energy density, cycle life, and technology maturity make them less versatile in most high-performance application scenarios. For applications requiring reliability, long life, and customized power solutions, we highly recommend exploring custom lithium-ion battery solutions that offer superior adaptability and proven performance. CM Batteries has 2000+ projects under its belt in this area. Contact us for a consultation on the best energy solution for you.

Also, you can compare in-depth in our detailed guide: Sodium-ion vs. Lithium-ion Batteries: Key Differences Explained, and make an informed decision for your project.