Battery Management System (BMS) is the brain of lithium-ion batteries. At CM Batteries, our CTO Wang has over 20 years of experience in battery management system design, specializing in BMS hardware and software with minimal energy loss and stable quality. The battery management systems monitor the individual cells working status and provide advanced safety features to prevent overcharging, over-discharging, overheating, and short circuit protection.

In addition, our battery management system design offers comprehensive monitoring for custom lithium-ion battery packs, including cell voltage tracking, cell balancing, and detailed health status readings for the entire battery pack by App and PC software operating manual 2025 Version computer (Click to download).

- Communication Protocol: TCP, UART, CAN (250k-1MB), and RS485.

- Professional R&D Team: CMB’s Engineering team with rich experience in battery management system design for various of li-ion battery pack applications for 10 years.

- Customize Service: CMB customizes unique BMS solutions to meet each customer’s need.

- Reputable MOS & ICs: CMB’s battery management system (BMS) is built with a reputable chipset with RICOH, Seiko, TI, and BQ.

Tailored Applications to Your Unique Landscape

Battery Management System Design Solutions

Cell Series

1S to 64S

Voltage Ranges

3.7V to 400V

Continuous Discharge Current

Continuous discharge current up to 200A

Battery Type

NCM and LFP (Lithium Iron Phosphate) batteries

Communication Interfaces

communication protocols including RS485, CAN, UART, and TCP

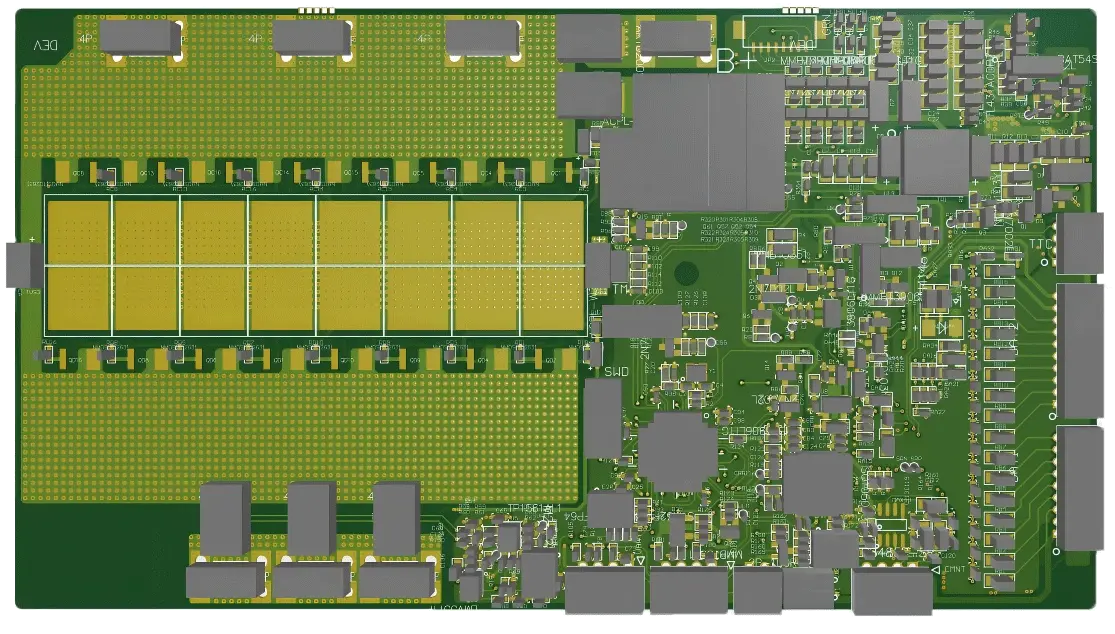

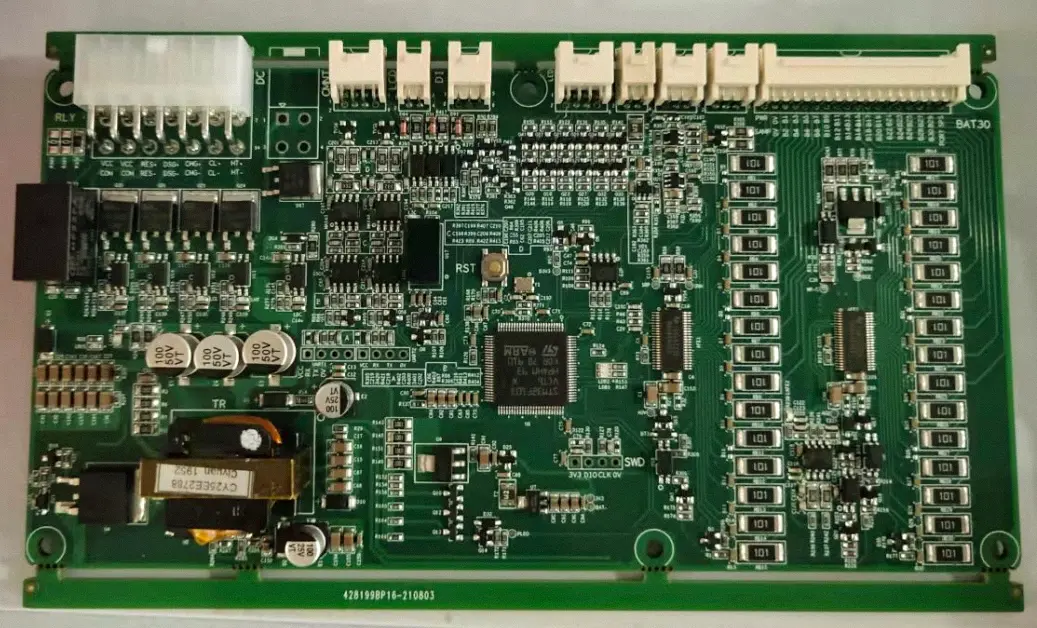

Compatible with 13S Relay BMS Soltuion

- Dimensions: 180mm * 100mm * 20mm

- Continuous charge/Discharge current: 100A

- Wake-up methods: Switch wake-up(DI port signal), communication wake-up(CAN/UART)

- Functions: Heating, condensation, LED light board, switch

- Communication methods: Isolated CAN(250k-1Mbps), Non-isolated UART (for host computer)

- Temperature monitoring: Includes dual NTC sensors (-20°C to +85°C, ±2°C accuracy) and Passive Balancing:Balancing current(30mA). Activation threshold: Cell voltage difference ≥30mV.

Compatible with 17-30S Relay BMS Soltuion

- Dimensions: 185mm * 95mm * 30mm

- Maximum charge and discharge current: According to the actual relay

- Wake-up methods: Charging wake-up, switch wake-up, communication wake-up

- Functions: Heating, condensation, LCD, LED light board, switch

- Communication methods: Bluetooth, isolated 485, CAN. Non-isolated UART (for host computer)

- Temperature monitoring: Includes balancing and NTC (Negative Temperature Coefficient) thermistor

Everything You Need to Know About Battery Management System Design

Advantages Of Custom Battery Management System

- Monitor battery pack healthy by App & upper computer

- OTA firmware update

- Multiple protection with overdischarge & overcharge protection

- Deep sleep mode to make the battery pack with low self-consumption

- Multiple communication protocols: CAN,RS485,UART

BMS Functions

Basic Functions

- High voltage sampling of battery pack

- Current sampling of battery pack

- Temperature sampling of battery pack

- Voltage sampling of battery cells

- Temperature sampling of battery cells

- Over-voltage protection

- Over-current protection

- Over-temperature protection

- Insulation detection

- High voltage interlock (HVIL)

Core Functions

- Battery balancing

- State of Charge (SOC) calculation

- State of Health (SOH) calculation

- Static State of Power (SOP) calculation

- Dynamic State of Power (SOP) calculation

Application-Related Functions

- Collision detection

- Vehicle charging

- Fast charging

- Charger status monitoring

- Thermal status/demand

- Automatic cooling control

- Automatic heating control

- Pre-charging

- Wake/sleep mode

- Contactor status monitoring

- Vehicle Control Unit (VCU) communication

- Vehicle charger communication

- Fast charging communication

- Fault diagnostics

- Software updates and calibration

BMS Types

Passive Balancing

- Passive balancing is a commonly used method in battery management system design.

- It relies on resistors to dissipate excess energy from overcharged cells as heat.

- Passive balancing is cost-effective and simple but may not be as efficient as active balancing.

Active Balancing

- Active balancing uses electronic components such as switches and capacitors to redistribute energy.

- It is more efficient than passive methods, providing faster and more precise balancing.

- Active balancing is typically preferred for high-performance or high-capacity battery systems but can be more expensive.

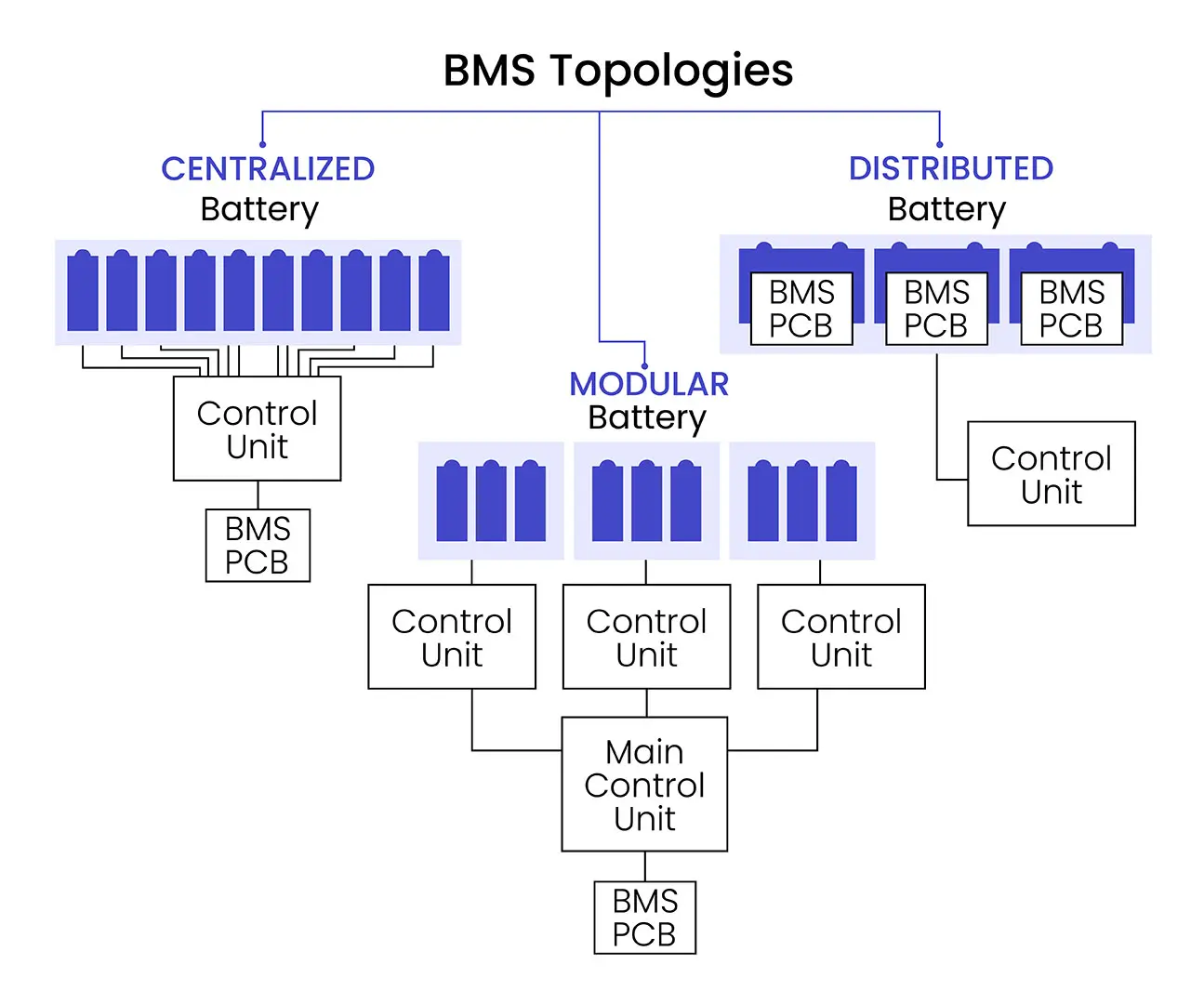

BMS Topologies

| Topology | Description | Advantages | Disadvantages | Application |

|---|---|---|---|---|

| Centralized | Single control unit monitors and controls the whole battery pack | Simple, easy to implement | Less reliable, bulky wiring | power tools, intelligent robots, IOT smart home , electric forklifts, electric bicycles, electric golf carts, etc. |

| Distributed | Each battery pack has its own BMS board | More reliable, scalable | More complex, expensive | Electric vehicles,Boat,etc. |

| Modular | Battery groups divided into modules with individual BMS | Flexible, scalable | More complex, requires communication | Container energy storage system (EMS), energy storage power station. etc. |

BMS Communication Protocols

CAN Bus (Controller Area Network)

- CAN Bus is a robust and reliable communication protocol. It enables real-time data exchange between components, ensuring seamless coordination within the battery system.

- CAN Bus is known for its high data transmission rate, fault tolerance, and suitability for complex BMS applications.

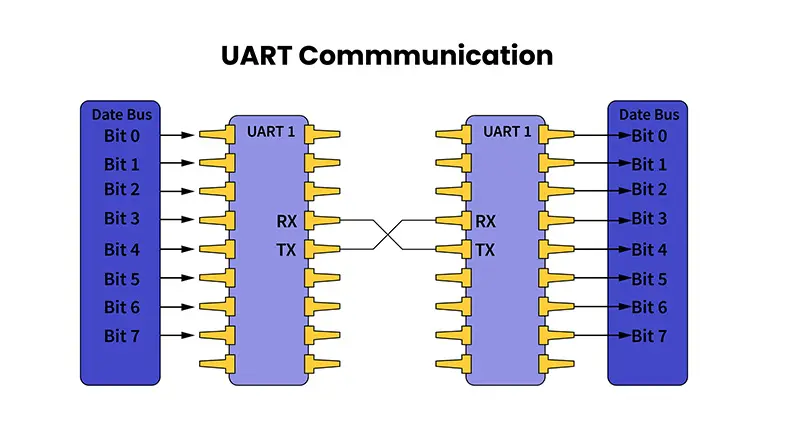

UART (Universal Asynchronous Receiver-Transmitter)

- UART is a fundamental communication protocol. It allows for serial data transmission. It is known for its simplicity and ease of implementation.

- UART is often used for basic communication tasks within the BMS, offering a straightforward way to exchange data between components.

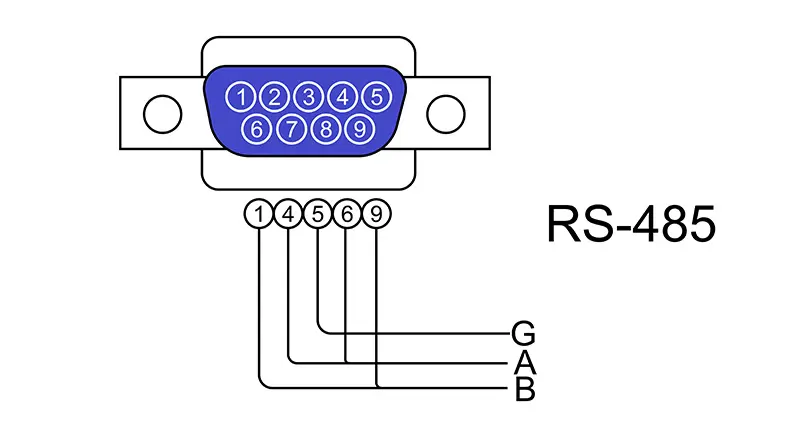

RS485 (Recommended Standard 485)

- RS485 is a widely adopted communication standard in BMS for applications that require longer communication distances and noise immunity.

- It’s well-suited for multi-node systems and offers differential signaling, ensuring reliable data transmission even in electrically noisy environments.

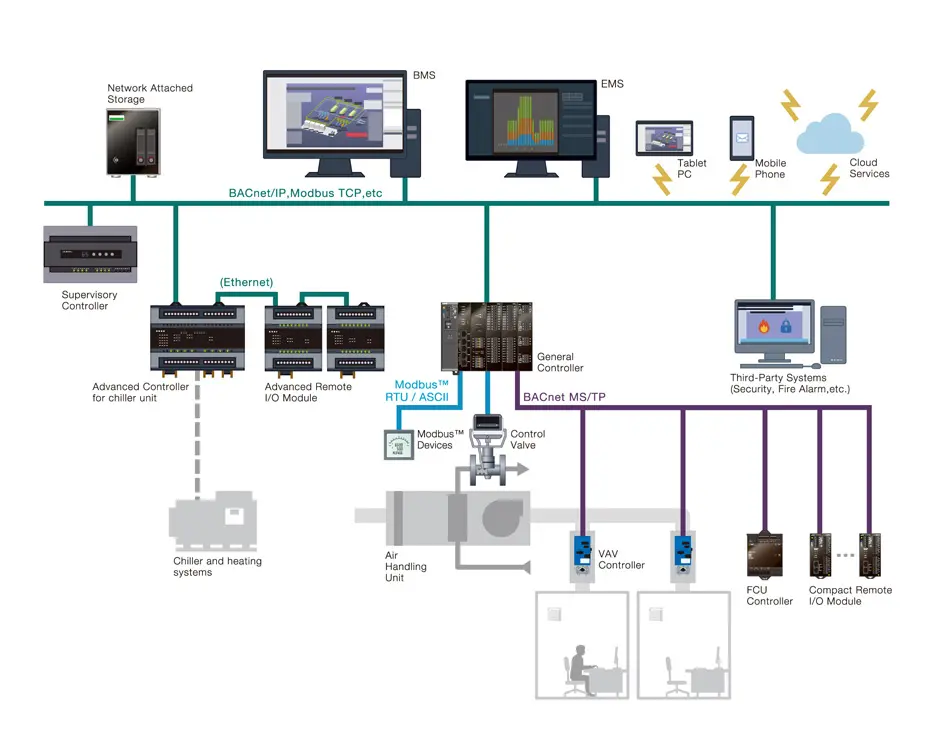

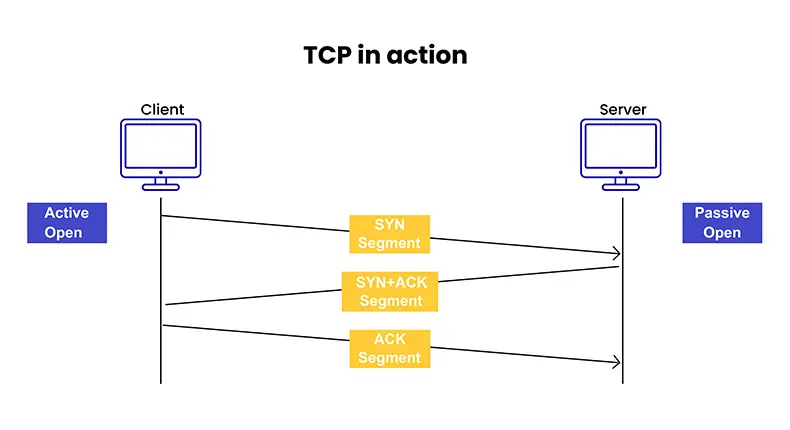

TCP (Transmission Control Protocol)

- TCP is a network communication protocol often used in BMS for remote monitoring and control. It enables secure and orderly data transfer over the internet or local networks.

- TCP ensures data integrity and reliability, where remote access from BMS data .

Key Factors Impact a Custom Battery Management System Design

Battery Characteristics:

- Chemistry: Different chemistry with different input voltage.

- Discharge & Charge Current: Specific discharge & charge current needs should be considered in the battery management system design.

- Special Functions: We’ll consider the needs of temperature, short circuits, balance, and weak currents.

Safety:

- Protection: Overcharge, over-discharge, short circuit, and thermal runaway protection.

Performance:

- Balancing: Ensures balanced charging of cells, extending battery life.

- Estimation: SOC (State of Charge) and SOH (State of Health) estimation to understand battery status and predict lifespan.

- Monitoring: Cell voltage, temperature, and internal resistance monitoring.

User Interaction:

- Interface: Graphical User Interface (GUI) or other interaction methods.

Reliability:

- Redundancy: Redundant design for critical components.

- Fail-Safe: Fail-safe mechanisms to reduce the risk of failures.

Environmental Adaptability:

- Factors: Resistance to extreme temperatures, humidity, shock, and vibration.

- Component Selection: Components that withstand harsh environments.

Scalability:

- Design: Support for future expansion of battery configurations.

Regulatory Compliance:

- Standards: Compliance with safety and industry standards such as UL, IEC.

- Regulations: Adherence to specific regulations applicable to the application or industry.

Firmware and Software:

- Development: Firmware and software tailored to specific needs.

Maintainability:

- Planning: Maintenance and repair plans.

- Accessibility: Secure access and repair.

Tailored Customization

Our design team can create custom battery designs for just about any device or machine.

Timely Delivery

Our efficient production and distribution process gets your product delivered in a timely manner.

Quality Guarantee

We stand by our products and guarantee you’ll be happy with your purchase.