There is an increasing demand for high-voltage lithium battery packs in high-power applications such as industrial AGVs, large robots, and commercial energy storage systems. These applications demand enhanced safety, efficient heat dissipation, and ease of maintenance, making modular battery pack designs the industry’s preferred solution.

Modular Li-ion battery packs integrate standardized cells and a unified BMS, support independent heat dissipation design between modules, adapt to various applications, and improve system compatibility and engineering deployment efficiency. It also achieves voltage and capacity advantages through flexible configuration of multiple voltage ranges of 12.8V, 25.6V, 38.4V, and above.

So, why choose modular battery packs? Let’s explore the critical benefits driving their adoption.

Flexibility and Scalability of Modular Battery Packs

Traditional standalone battery packs suffer from inherent design constraints: once installed, their capacity and performance are fixed, lacking scalability. As power demands increase, their rigid architecture struggles to accommodate higher loads. Additionally, their non-modular nature prevents component upgrades, causing them to fall behind evolving performance standards.

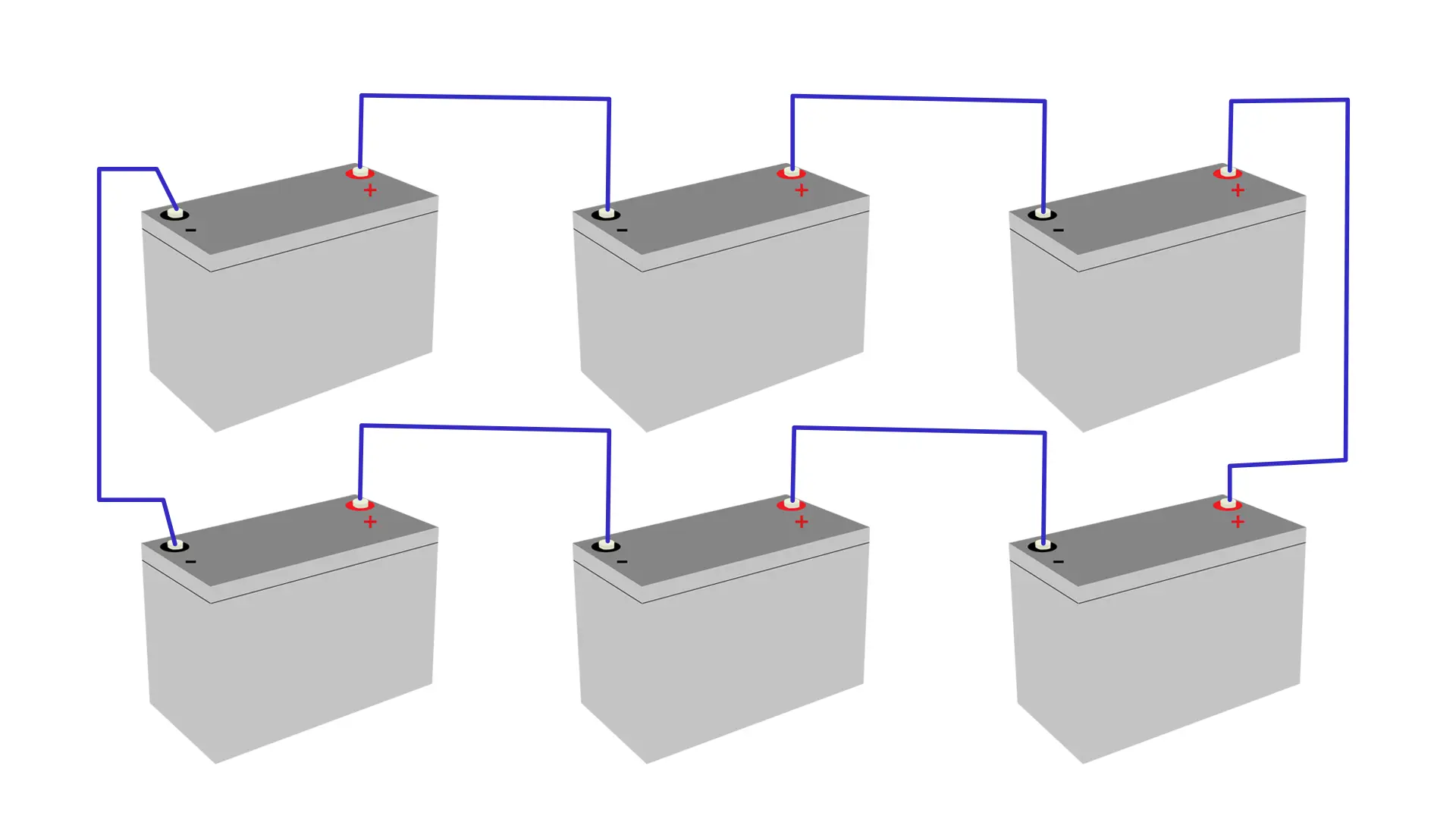

Unlike fixed-configuration battery packs, modular battery packs provide custom power solutions through flexible series and parallel connections. This scalable architecture allows for voltage adjustment, capacity expansion, and hybrid configurations.

For example, 12V modules can be connected in series to form a 24V or 48V modular battery pack to increase voltage output. If higher power output and current are required, parallel connections can be achieved. Besides, A combined series-parallel connection (e.g., 2 series + 2 parallel) can also be applied to expand the voltage and capacity. For modular battery pack assembly, the cell performance consistency should be well-controlled. We should be careful with the heat dissipation and ensure easy maintenance. The best connection method depends on the application’s key requirements (voltage vs. capacity priority), budget, and reliability needs. For more details, we have explained series, parallel, and series-parallel connections for 12V battery modules.

Modern battery module designs often include active balancing circuits and thermal management systems to optimize performance.

Smart BMS Design for Modular Battery Packs

The BMS design forms the operational backbone of any battery system, integrating multiple specialized components into a cohesive management platform.

These include temperature sensors, current sensors, control units, and communication circuits. They work together to create an integrated BMS system through intelligent layout and connection.

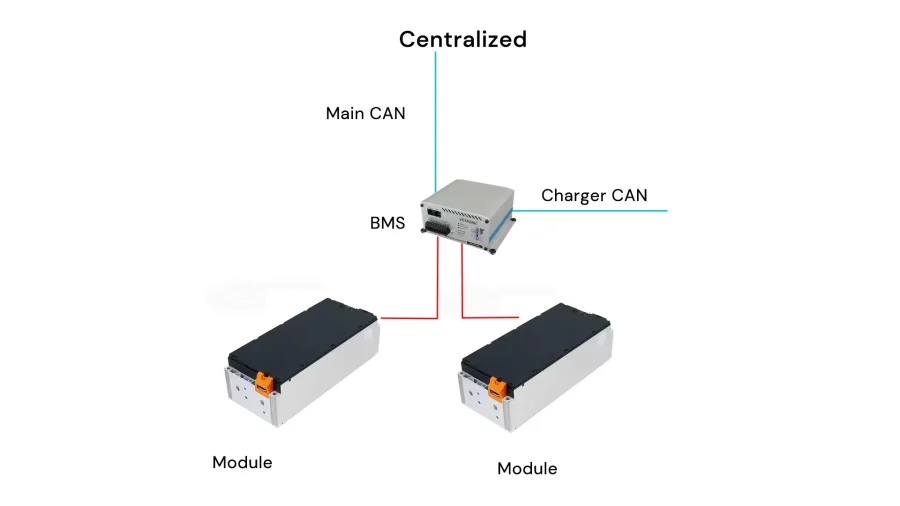

Centralized BMS Architecture

The centralized BMS architecture offers distinct advantages for low-capacity, low-voltage applications, including power tools, robots, and IoT smart homes. In the high-voltage area, it is responsible for collecting the voltage of a single battery and monitoring the voltage and insulation resistance of the entire system. The low-voltage area covers key components such as power supply circuits, CPU circuits, CAN communication circuits, and control circuits.

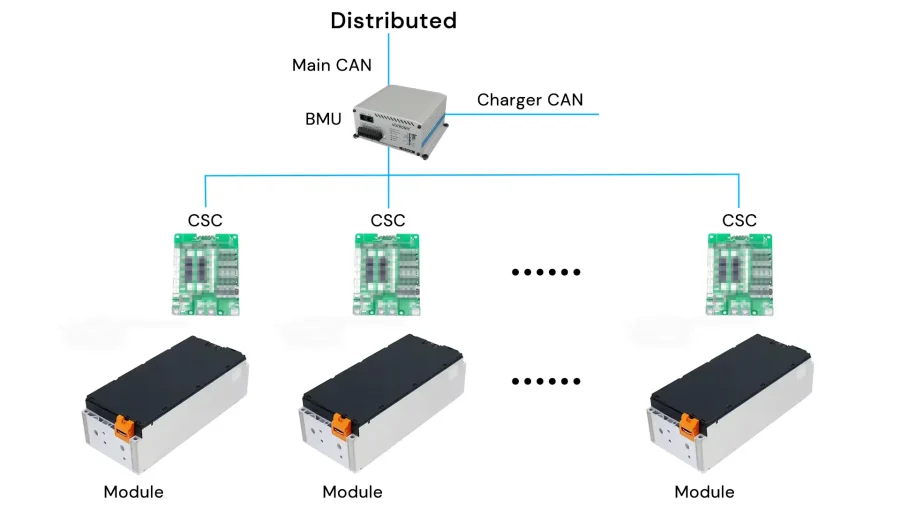

Distributed BMS Architecture

The distributed BMS architecture is specifically engineered for demanding energy applications, including electric vehicles and energy storage systems. Its modular design makes it easy to cope with large battery systems.

In a distributed architecture, the Clave Control Unit (CSC) is responsible for performing voltage and temperature checks and managing cell balancing. The High Voltage Management Unit (HVU) focuses on monitoring the total battery voltage and insulation resistance. The Battery Management Unit (BMU) is responsible for evaluating the battery status, management, and communication.

A centralized BMS integrates all management functions into a single controller, making it efficient for small, low-voltage systems. However, its processing speed and scalability may become limited as the system grows. In contrast, a distributed BMS provides better reliability and flexibility for complex, high-capacity battery systems. Each module operates independently, enabling precise measurement, improved heat distribution, and better fault isolation.

Both centralized and distributed BMS architectures can integrate RS485/CAN485 communication protocols to achieve high-precision voltage, current, temperature, and cycle monitoring. However, their implementation methods and performance differ based on system design.

Hot-Swap Lithium Modular Battery Pack Technology

Hot-swap capability has become a common requirement for modular battery packs. This addresses a key limitation of standard battery systems – the need to power down equipment during battery replacement, resulting in operational downtime and lost efficiency. These interruptions are particularly unacceptable for critical applications like medical equipment.

Modular battery packs with real-time operation capability solve this problem by allowing:

- Replacement of individual faulty modules without system shutdown

- Continuous equipment operation during maintenance

- Dramatically improved operational efficiency

Thermal Management System of Modular Batteries

Thermal dissipation presents a critical challenge in large battery systems, making modular battery design one of the most effective approaches to address the issue. The thermal management system integrated into the modular battery pack ensures device safety during operation. Heat is generated during the battery’s charging and discharging processes. If not dissipated promptly, this heat can lead to capacity degradation and even thermal runaway.

The modular battery pack achieves complete thermal control through a three-tiered approach combining structural engineering, material science, and intelligent system management.

1. Structural Thermal Management

- Each module incorporates dedicated heat dissipation zones

- Integrated cooling channels support both air and liquid cooling systems

- High-efficiency thermal interface materials (e.g., graphite sheets) enhance heat transfer

- Fire-resistant barriers between modules contain thermal runaway events

2. Intelligent Control System

- Distributed temperature sensors provide real-time module-level monitoring

- Adaptive cooling regulation (fan speed/pump flow) responds to thermal loads

- Predictive algorithms enable proactive thermal risk mitigation

- Multi-level safety alerts for abnormal temperature conditions

3. Application-Specific Flexibility

- Configurable cooling solutions (air/liquid/thermoelectric)

- Scalable architecture for varying power densities

- Robust performance in extreme environments.

This integrated approach ensures optimal thermal performance while maintaining system safety and reliability across diverse applications. The modular design enables precise temperature control at the individual cell level while preventing thermal propagation throughout the battery system.

Faster Charging of Modular Battery Packs

Modular battery systems achieve superior charging speeds through three key mechanisms.

1. Standardized small-format cells (18650/21700) advantages:

- Shorter ionic diffusion paths (30-50% reduction)

- Lower internal resistance (15-25% improvement)

- More efficient charge transfer reactions

2. Parallel cell configuration

- Divide the total current proportionally

- Maintains <1C rate per cell during 3C system charging

- Reduces individual cell thermal load by 40-60%

- Scalable current capacity

- Independent thermal management zones

3. Active safeguards prevent:

Distributed BMS architecture features:

- Per-cell voltage monitoring (±5mV accuracy)

- Temperature sensing (±1°C precision)

- Dynamic current balancing

Active safeguards prevent:

- Localized overheating

- Charge current bottlenecks

- Performance degradation

Unlike single-cell designs, modular battery architectures enable superior fast-charging capabilities. It will boost the charging speed for modular battery packs.

Modular Battery Solution Design Costs

Due to their integrated CMU control systems and intelligent BMS technology, modular battery packs have 20-30% higher initial cost than standard battery packs.

Modular battery packs enhance total system lifespan through selective module replacement, offering distinct advantages over conventional ones. However, the traditional battery packs usually suffer a drastic decline in performance after 5-8 years since they cannot be refurbished components cannot be changed separately, and must be scrapped entirely. Modular designs can prolong the system’s life to 10-15 years, minimizing equipment update frequency and expense.

Unlike traditional battery packs that become waste once exhausted, modular systems adhere to circular economy principles. Retired modules can still be used for low-power devices, such as emergency lights and toys. Unused modular battery packs can be easily dismantled and have standard interfaces, which makes sorting, testing, and recycling easier.

Enhanced Transportability and Seamless Compatibility

The main advantage of modular battery packs is their transportability. They can be disassembled into smaller parts, making them easier to handle, transport, and even place on airplanes. However, when scaling or upgrading the system, compatibility becomes a challenge. Substituting or adding modules requires testing to ensure performance coordination and electrical safety across the whole system. This trade-off highlights the need for careful planning in modular design, balancing flexibility with precise integration.

In conclusion, modular battery pack design is no longer a technical option—it has become an essential solution for building flexible, reliable, and sustainable energy systems. However, designing a modular battery involves complex considerations, and overlooking any single aspect can lead to safety risks.

With over 100 successful case projects in customized modular battery systems, CM Batteries prioritizes safety. Our engineering team adheres to industry standards, delivering custom modular battery solutions for every client. From precise battery parameter matching and robust protection circuit design to optimized charging/discharging strategies, every detail is evaluated to ensure reliable and safe operation across diverse applications.

If you have questions or requirements regarding modular battery packs, please feel free to contact your exclusive consultant.