To extend IoT battery life, the key is to minimize power consumption while maintaining system performance and reliability. IoT devices often operate in harsh or remote environments, where frequent data transmission, temperature changes, and high current spikes quickly drain power sources.

In this article, we’ll explore what shortens IoT battery life and share practical strategies—from battery chemistry selection to smart power management—to help you design longer-lasting, energy-efficient IoT power systems that meet modern connectivity demands.

Why IoT Battery Life Often Falls Short?

The lifespan of IoT device batteries depends on more than just their capacity rating. High-load workloads and power consumption, battery chemistry, communication proposal, temperature and environmental conditions contribute to their long operating time. Hence, understanding these influencing factors is the first step to manufacture and maintain a reliable and long-lasting IoT battery pack.

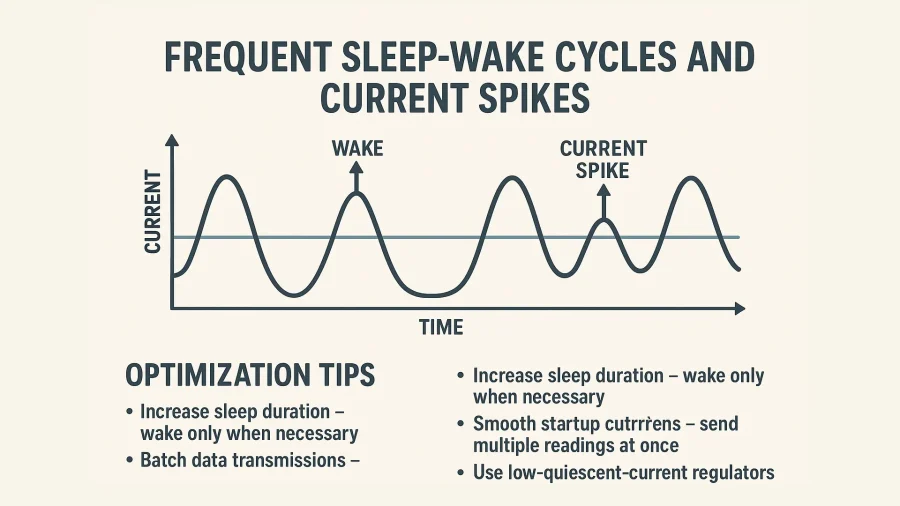

Frequent Sleep-Wake Cycles and Current Spikes

IoT devices operate in sleep mode for most of their lifetime to conserve energy, waking periodically to transmit data or perform tasks. However, IoT device wakes up from sleep mode and creates short bursts of high current which shorten its lifespan(Kozłowski et al., 2019).

These recurring current surges generates localized stress and micro-cycling on the electrodes with local heating and SEI film growth, leading to the shedding of active materials and capacity decrease. This process greatly reduces IoT battery life.

Communication Protocols

Different communication protocols like NB-IoT, LTE-M, BLE, and LoRaWAN have vastly different energy profiles. According to Rajab et al. (2023) , protocol choice directly affects IoT battery life.

The following table for illustrating how different protocols affect power efficiency and battery life. And we compare several major IoT communication technologies and coordinating battery performance and types.

| Communication Protocol | Power Characteristics | lmpact on Battery Life | Battery Performance Requirements | Recommended Battery Types |

| LPWAN (NB-IoT, LTE-M, LoRa) | Ultra-low power, intermittent communication, low data rate | Devices remain in sleep mode with minimal energy consumption. | Low self-discharge, Wide temperature tolerance, Stable voltage output, High energy density | LiFePO4 battery; High-temperature lithium battery |

| LAN (Wi-Fi, Ethernet, Bluetooth) | High power consumption, high data rate, continuous connection | Frequent large data transmissions shorten battery lifespan | Good thermal management, Stable cycle life | NCM battery; LiPo battery |

| PAN (BLE, Zigbee, Thread) | Low power, short-range, periodic wake-up | Long standby, short active transmission. Small-capacity batteries last several years | Lightweight design, Special-shaped cells, Fast voltage recovery | LiPo battery |

| Cellular Network (3G/4G/5G) | High speed, wide bandwidth, Strong real-time performance | Frequent network switching cause battery aging | High discharge rate, Wide temperature adaptability, Voltage fluctuation resistance | NCM lithium battery; High-temperature lithium battery |

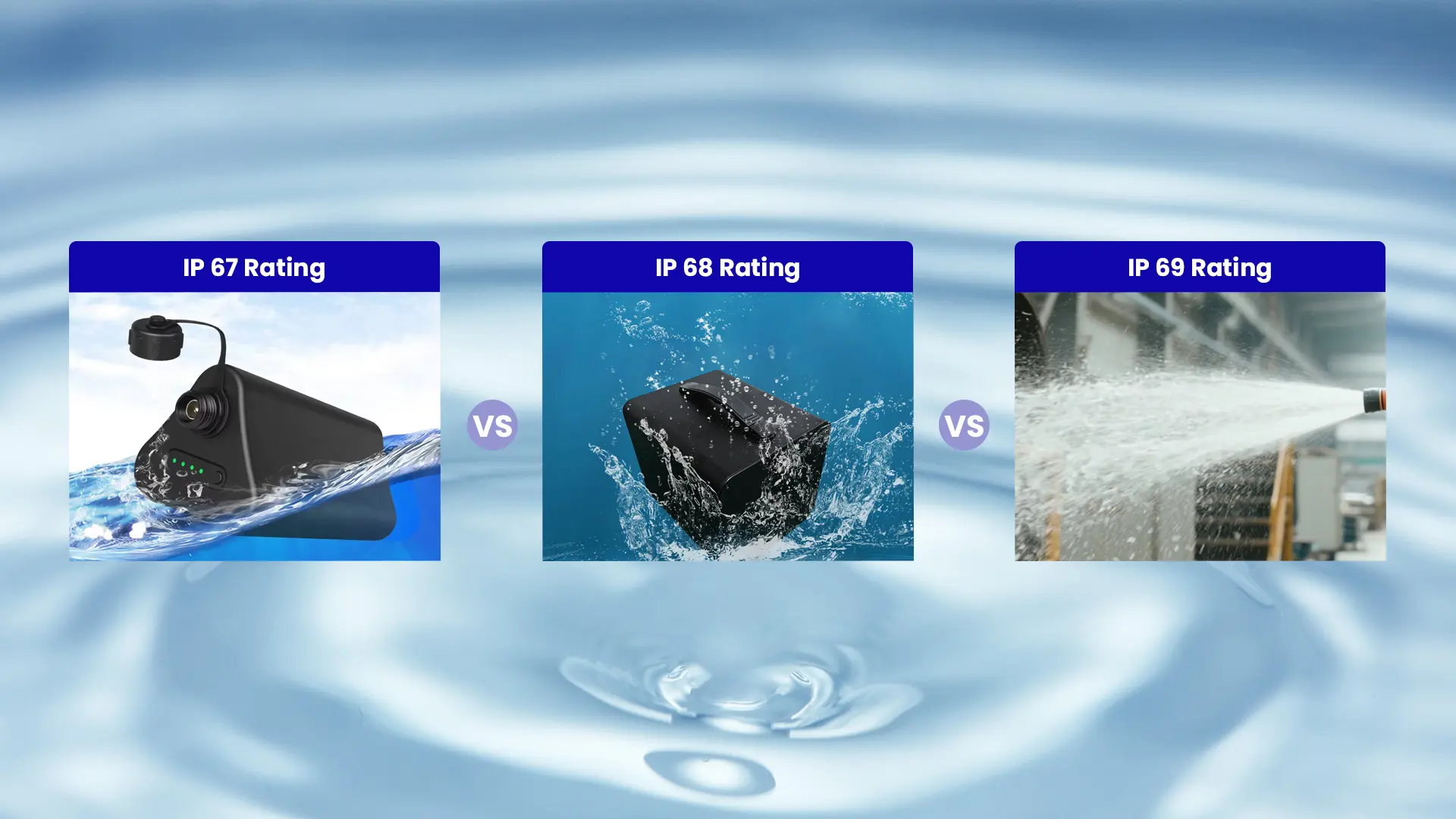

Temperature &Environmental Challenges

Extreme cold, heat, and humidity are major contributors to IoT battery degradation.

| Factors | Chemical Effect on Battery | Effect on IoT Battery Life | Applications |

| Low-temperature Environments (Northern Europe, Canada, or High-altitude Regions) | Reduces ion mobility, reaction rate and increases internal resistance | Leads to lower available capacity and unstable power output | GPS trackers for logistics in cold regions, outdoor weather stations |

| High-temperature Environments (Vehicle Interiors, Industrial Sites, Hot Regions) | Accelerates electrolyte decomposition, SEI growth and causes battery aging | Causes faster capacity fade, swelling, and shorter cycle life | Industrial IoT nodes, solar-powered gateways, outdoor solar camera |

| High Humidity | Promotes corrosion, moisture ingress and seal failure | Results in increased self-discharge, leakage, and reduced reliability | Tropical soil sensors, coastal monitoring stations, smart water meters |

- High temperatures speed up electrolyte decomposition and cause swelling.

- Low temperatures increase internal resistance and reduce available capacity.

- Humidity leads to corrosion and leakage (e.g., LiPF₆ → HF acid reaction).

Designing batteries with wide-temperature chemistry and proper sealing ensures reliable operation under any condition.

Mechanical Stress and Vibration

IoT devices exposed to continuous vibration, impact, or thermal cycling experience connector fatigue, increased resistance, and heat buildup.

These stresses accelerate electrolyte aging and cause electrode delamination, leading to reduced capacity and shortened lifespan. Reinforced tab welding, vibration-resistant housing, and flexible interconnections are key to maintaining performance stability.

Design Strategies to Extend IoT Battery Life

To overcome above challenges, the engineers need to take a holistic approach to combine battery chemistry selection, cell design, efficient hardware, and smart power management.

Choose the Right Battery Chemistry

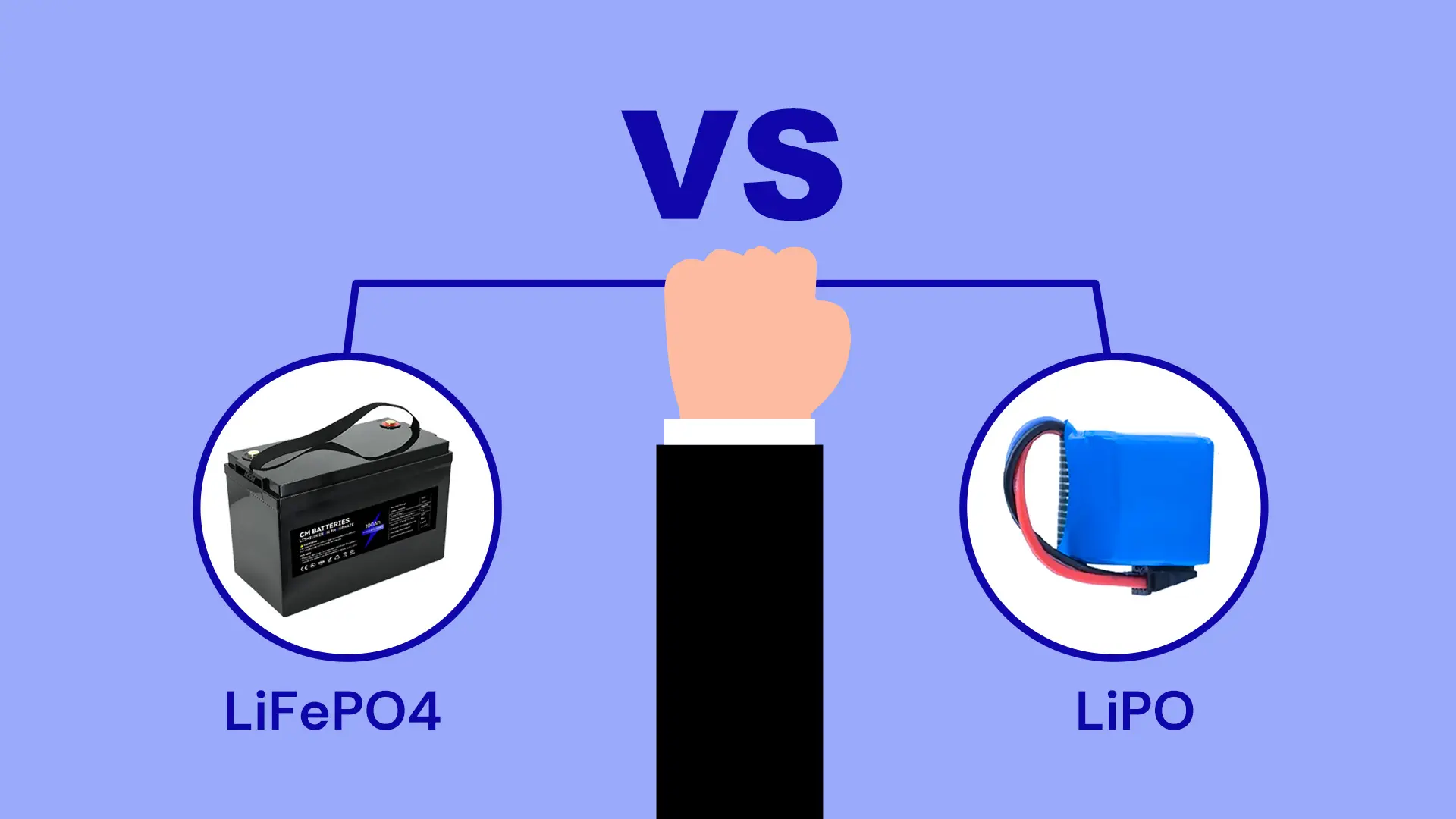

Right battery chemistry is the cornerstone of extending IoT battery life. Devices using LTE/5G or other high-power communication protocols require batteries can handle frequent, high-current pulses, while sensors in deep sleep mode require battery chemistry that maintain capacity during inactivity period.

Select a chemistry that fits your device workload:

- LiFePO4 – excellent safety, long life, wide temperature tolerance

- NCM / LiPo – high discharge rate, ideal for data-intensive IoT nodes

Read our engineering guide on choosing the right battery for IoT devices for detailed comparison and guidance on selecting the best battery for your IoT device.

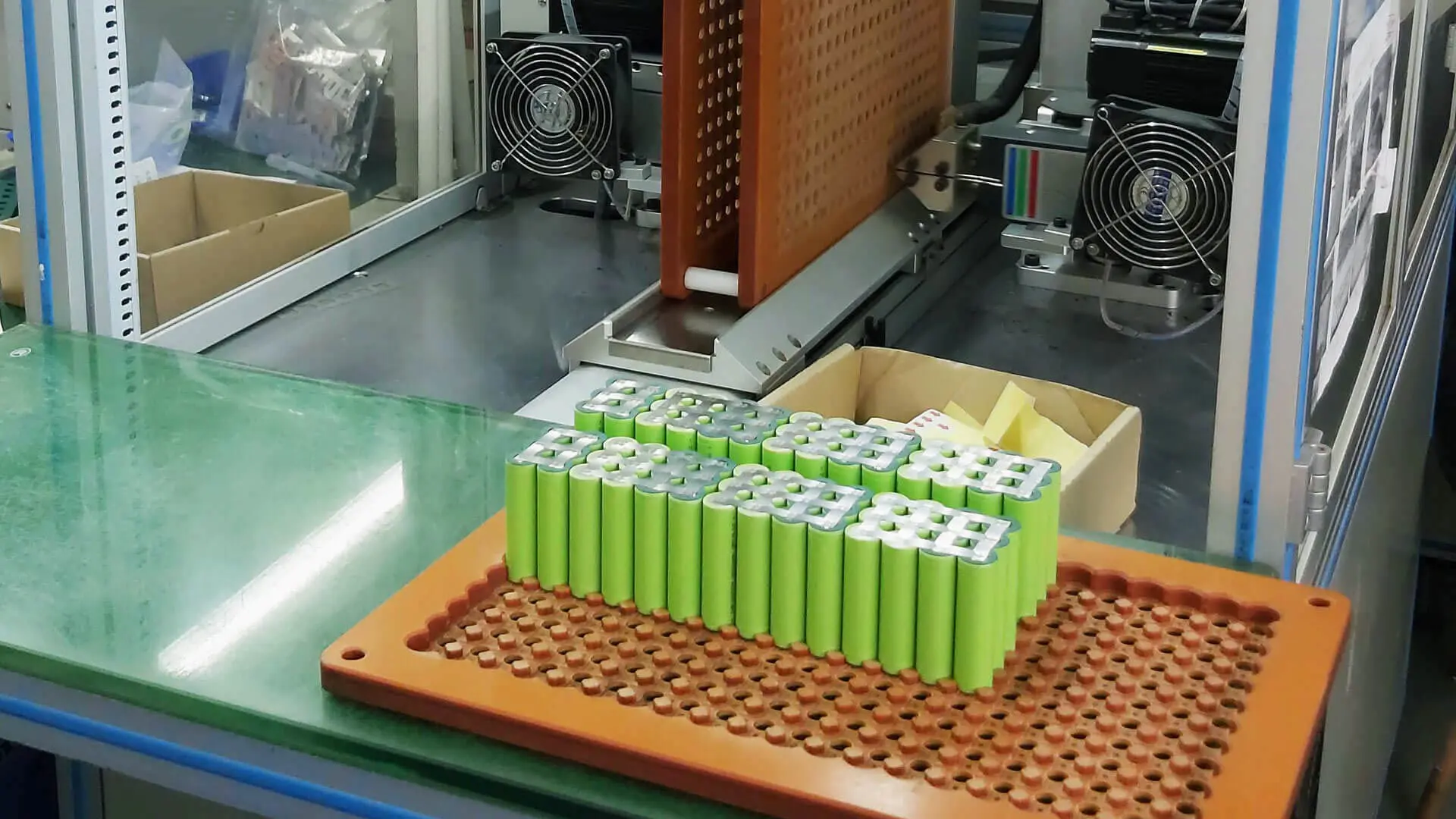

Optimize Cell Design and Matching

IoT battery pack life depends not only single cell itself, but also hinges on the cell design, cell matching and reliable assembly.

A well-balanced IoT battery pack performs longer. Matching cells by capacity and resistance minimizes internal stress and uneven heating.

Proper layout and cooling design (air/liquid channels) enhance stability and extend battery service life.

Explore our battery manufacturing process for details.

Hardware and Component Selection

Start with low-power hardware components, such as microcontrollers and sensors, and make sure the device’s actual power consumption matches its theoretical specifications. Choosing high-capacity batteries( up to 1000mAh for compact IoT devices) can significantly extend the device’s operating time.

Implement Smart Power Management

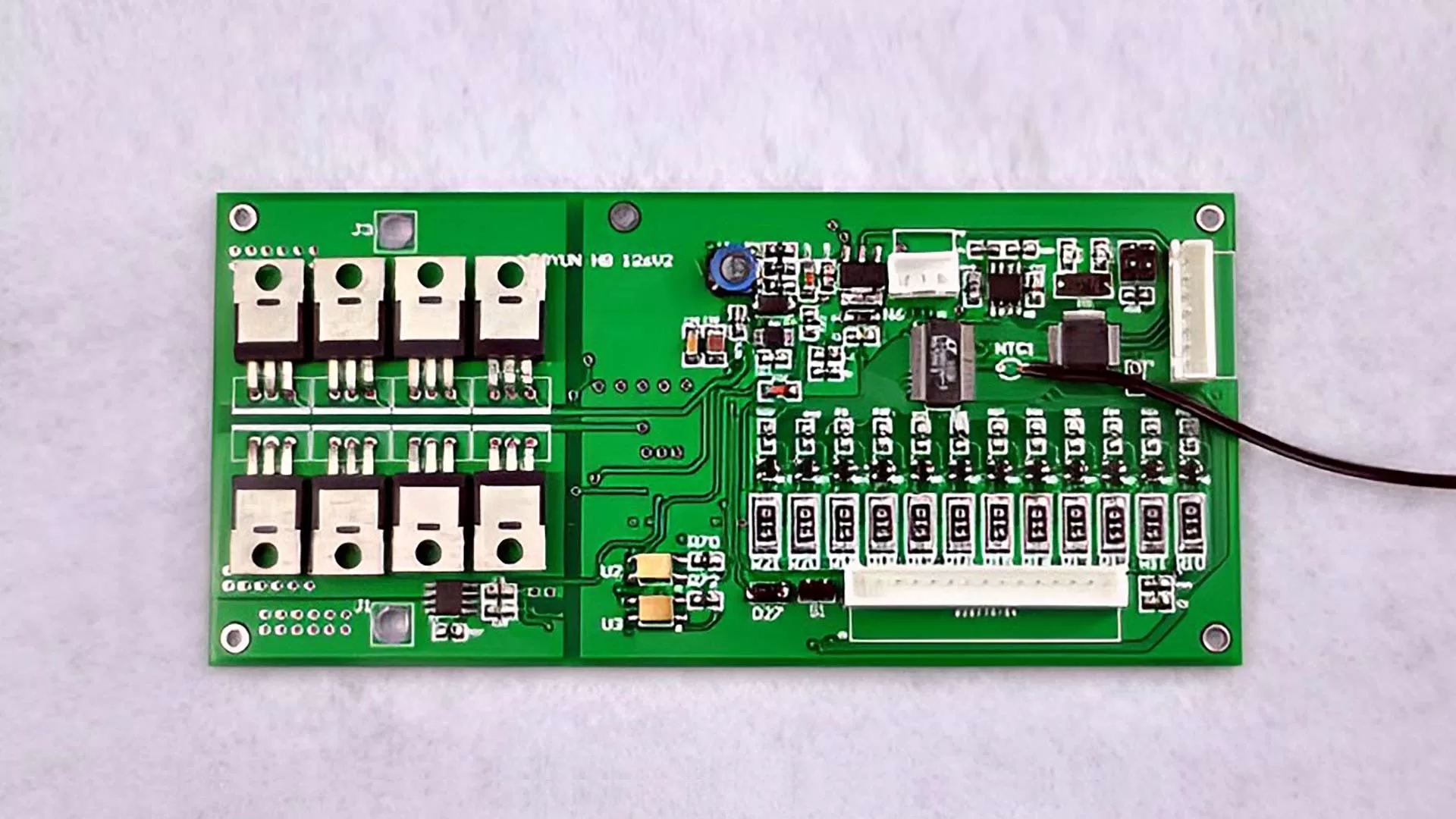

Smart battery management integrates temperature protection, capacity prediction, and control center.

- NTC Thermistor – detects overheat or overcool conditions.

- Fuel Gauge – estimates capacity and predicts battery aging.

- BMS Control Center – ensures charging safety, data logging, and communication with the device.

For more information about BMS, you can find it here: Custom BMS Design for Battery Packs.

For IoT devices operating under different conditions, smart power management adjustments can make a big difference.

- Dynamic transmission power control: Adjust transmission power based on signal quality and distance from the base station. Devices located closer can transmit with lower power, reducing energy consumption.

- Deep sleep mode: Keep the device in sleep mode most of the time and only wake it up for data transmission. Firmware can dynamically adjust the sleep duration to balance performance and power use.

- Ship mode: When devices are idle or stored for long periods, disconnect the battery to minimize standby power draw — ideal for equipment that may not be used for months.

Low-Power Design for Different IoT Devices

To achieve efficient low-power performance:

- Disable unnecessary peripherals, such as communication modules or sensors, when they’re not in use.

- Use shallow or deep sleep modes to reduce power drain during idle periods.

- Optimize firmware logic to limit data transmission frequency and minimize retransmissions. For example, under poor network conditions, use an adaptive retransmission mechanism to reduce overall energy consumption.

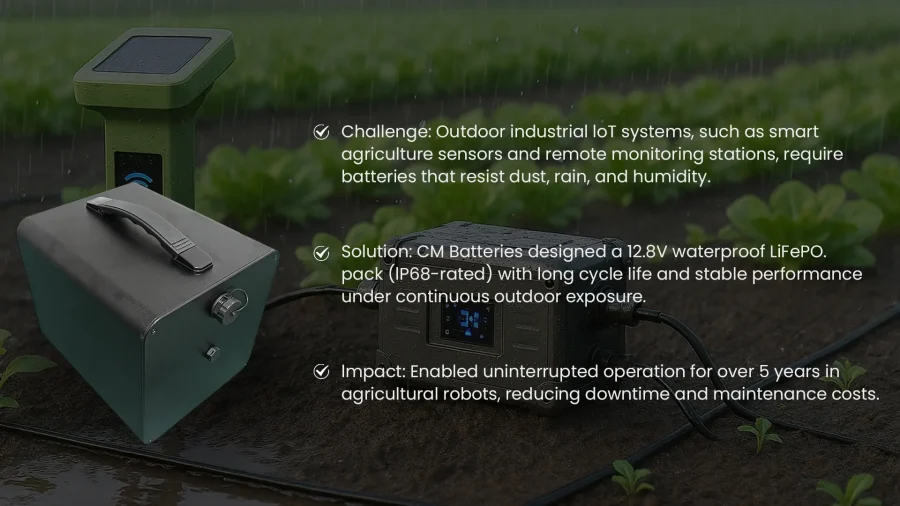

Case Study: 12.8V 105Ah LiFePO4 Battery Pack Extending Industrial IoT Device Lifetime

Recently, an agricultural IoT customer approached us, seeking a battery solution that extend the operating life for their remote soil moisture sensors and automated water pumping systems—critical tools for precision fertilizer application in modern organic farming.

IoT battery life is a key factor in ensuring system reliability and maintenance costs. In remote soil sensor and water pump system, traditional batteries fail to meet required lifespan. They cannot withstand the frequent data collection, wireless transmissions, and surge currents, leading to rapid capacity fade and maintenance.

To meet these demands, the battery must support the pump’s peak current, provide sufficient capacity for long-term operation, and withstand water, dust, and temperature fluctuations.

To address this challenge, we provided our customer with our 12.8V 105Ah IP68-rated modular LiFePO4 (LFP) battery pack.

Consumer Requirement

During irrigation in the fields, water pumps failed to start and soil moisture sensors stopped sending data for several days, resulting in irrigation delays and increased maintenance costs. Their major problems include.

- How can sensors and pumps run for months without constant battery changes?

- Can battery handle high pump currents and harsh weather?

- What if more capacity or voltage is needed later?

Key Design Solution

- LiFePO4 chemistry boasts high stability and capacity retention. It ensures the battery handle frequent soil moisture sensor readings and high current sudden bursts. This addresses the reducing frequent battery replacement needs.

- Wide temperature technology ensures uninterrupted soil monitoring and irrigation, whether on scorching summer days or chilly winter nights.

- IP68 waterproof housing protects the battery from rain, dust, and muddy field environments, ensuring continuous operation in harsh agricultural conditions.

- Smart battery management system equipped with an NTC thermistor and fuel gauge monitors temperature, state of charge to extend IoT battery life. Water pumps and soil sensors operate smoothly without unexpected downtime.

- Battery system supports low-power communication protocols like LoRa and NB-IoT, enabling long-distance data transmission without sacrificing energy due to frequent wake-up calls.

Final Insights on IoT Battery Life Optimization

To extend IoT battery life, it’s essential to focus on three core pillars: selecting the right battery chemistry, optimizing cell and hardware design, and implementing intelligent power management that adapts to real operating conditions. By integrating these principles into system design, IoT devices can achieve longer uptime, reduced maintenance needs, and enhanced reliability—even when operating in harsh or unpredictable environments.

As a custom battery pack manufacturer, CM Batteries specializes in designing custom battery pack solutions that combine stable chemistry, advanced battery management systems (BMS), and modular adaptability. Our batteries help IoT device manufacturers increase uptime, reduce maintenance costs, and meet environmental, social, and governance (ESG) standards, providing a reliable and sustainable power foundation for the next generation of connected devices. If you have any requests, please contact us.