Prismatic and cylindrical are two popular types of lithium-ion battery cells. Cylindrical cells excel in superior heat dissipation, excellent consistency, and durability, but at the expense of limited energy density and reduced space efficiency. Prismatic cells boast advanced safety, volumetric utilization, and flexible design at the trade-off of bulkiness and increased cost.

While cylindrical batteries have long dominated the lithium battery market, prismatic batteries are quietly gaining attention with their unique advantages. Let’s take a closer look at the strengths of both.

Understanding Prismatic and Cylindrical Cells

What is a Prismatic cell?

A prismatic cell has a rectangular or square shape and a flat, rigid housing. It is manufactured using winding or stacking processes and is enclosed in an aluminum or steel prismatic casing. Its shape can be customized based on specific requirements. This structure makes it stand out for enhanced energy density and flexible structure design.

The positive and negative terminals of a prismatic battery are located at opposite ends and connect to the circuit board through connectors. These batteries typically use either solid-state or liquid electrolytes to store and release energy. With their higher energy density, long lifespan, and reliable stability, prismatic batteries have become the preferred power source for many consumer electronics.

For the same volume, stacked prismatic cells can deliver more energy at once, resulting in better performance, while flat prismatic cells hold more energy overall, offering greater durability.

What is a Cylindrical cell?

A cylindrical cell has a round shape and involves a metal can, a diaphragm, and wound electrodes that are evenly distributed. It is manufactured using a winding process and housed in an aluminum casing with strong impact resistance. Thus, cylindrical cells boast excellent heat dissipation performance and superior consistency across cells.

In short, cylindrical batteries are small and round, making them easy to stack in devices of various sizes. Unlike other battery formats, their shape helps prevent swelling, a problem caused by gas buildup inside the cell casing.

8 Key Differences Between Prismatic and Cylindrical Batteries

Prismatic and cylindrical cells exhibit a huge difference. Shape isn’t the only factor that sets prismatic and cylindrical cells apart. The key differences lie in their size, the number of electrical connections, and their power output.

| Features | Cylindrical Cell | Prismatic Cells |

| Shape | Round shape | Rectangular or square shape |

| Structure | Contain metal can, diaphragm and wound electrodes | Flat rigid housing with stacked electrodes |

| Durability | Metal cans with physical protection | Weak rigid housings and easily damaged |

| Thermal Management | Great. Jelly-roll structure enhances heat dissipation | Poor. Layer structures generates more heat |

| Cost | Lower costs thanks to mature supply chain | Higher manufacturing cost |

| Space efficiency | Low. Exist gap during assembly. | High. Tight package method. |

| Design flexibility | Less shape flexibility | High; Multi-layer stacking for modular design |

| Applications | Ebikes, Medical Devices | Marine Boats, Robots |

Size and Shape

- A prismatic cell is larger and heavier than a cylindrical cell. It requires more space to dissipate heat and offer a flexible design to customize the battery pack. Prismatic cell sizes vary based on tailored needs, from 30×20×3mm to 300×100×50mm. A single prismatic cell can hold as much energy as 20 to 100 cylindrical cells.

- Standard cylindrical cells involve 18650 cell(18×65mm), 21700 cell(21×70mm) and 26650 cell(26×65mm). 4680(46×80mm) is the common large cylindrical battery cell. Large cells cause increased internal resistance, poor thermal management, and high mechanical stress, which is hard for large-scale series and parallel connections.

Voltage and Capacity

Cylindrical batteries may store less energy than prismatic batteries, but they deliver more power. This means cylindrical cells can release energy faster than prismatic cells. The reason is that they have more connections per amp-hour (Ah). As a result, cylindrical batteries are ideal for high-performance applications, while prismatic batteries are better suited for maximizing energy efficiency.

- A cylindrical battery cell has low cell capacity. They feature compact size and excellent heat dissipation, supporting high-rate discharge power output.

- Prismatic battery cells offer high cell capacity. And they have limited high-rate discharge and low cost, ideal for large-capacity energy storage.

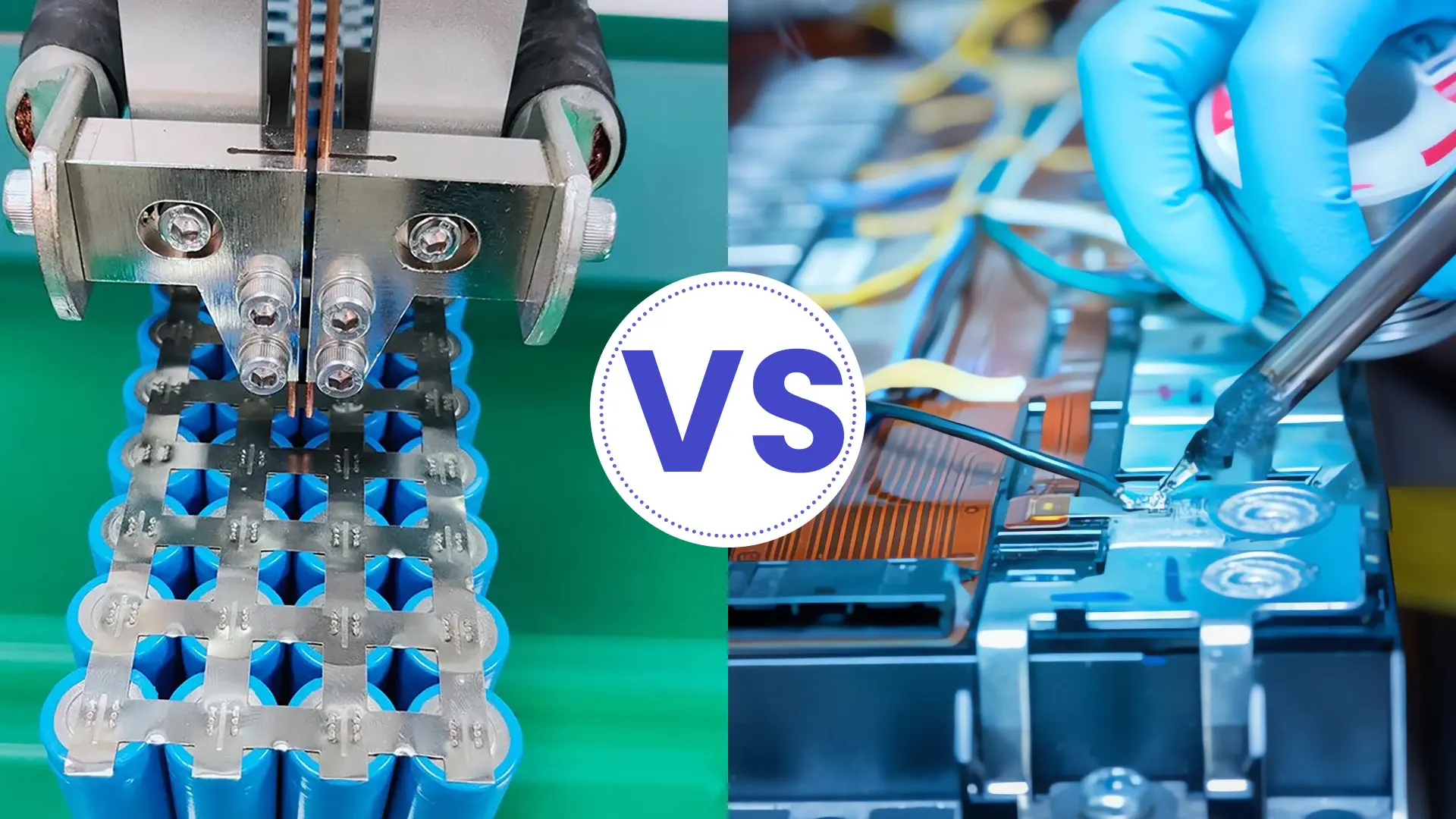

Structure and Construction

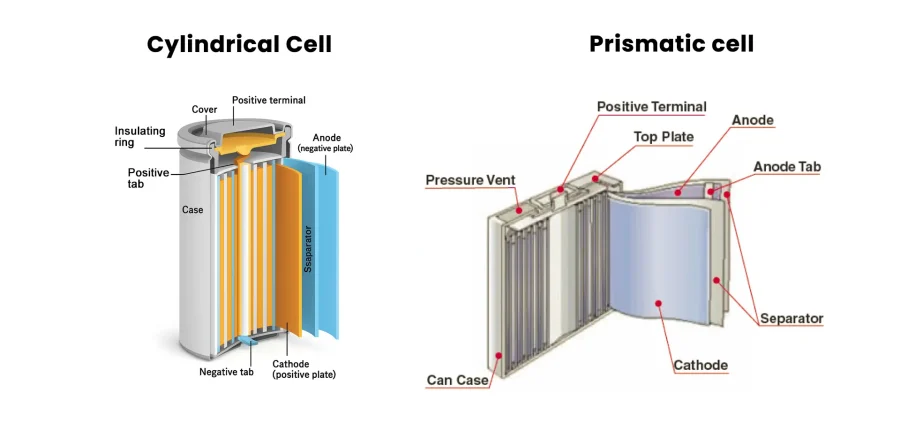

Internal Structure

- Prismatic Batteries: Electrode sheets are usually stacked in layers, which increases space utilization but requires careful optimization of heat dissipation paths.

- Cylindrical Batteries: Electrode sheets are wound in a spiral, forming a “jelly roll” structure. This design allows even heat dissipation, though gaps remain when cells are grouped.

Shape Construction

- Prismatic Batteries: Designed in polyhedral shapes (such as hexagonal or rectangular), typically enclosed in an aluminum alloy casing. The positive and negative terminals are located at opposite ends and connect to the circuit board through connectors. With their flat or rectangular design, the dimensions can be customized, making them well-suited for high-density stacking. Prismatic cells can be packed tightly together (e.g., BYD’s hexagonal prismatic cells), achieving over 20% higher space utilization compared to cylindrical cells.

- Cylindrical Batteries: Made by winding electrode sheets (cathode, separator, anode) into a metal cylinder. They offer strong mechanical stability and uniform internal pressure distribution. While their round cross-section leads to wasted space when grouped, their modular design simplifies BMS management.

Gravimetric and Volumetric Energy Density

Energy density measures a battery’s energy storage efficiency based on its volume or weight.

- Cylindrical cells deliver a higher gravimetric energy density of 200-260 Wh/kg due to their compact winding structure compared with 180–250 Wh/kg for prismatic cells.

- Prismatic cells shine in 600–750 Wh/L volumetric energy density thanks to a multi-layer stacked structure that reduces space loss. By contrast, cylindrical batteries have an energy density of 500-700 Wh/L, due to the larger gaps in the round structure and the bulky steel casing.

| Types of battery cells | Gravimetric Energy Density (Wh/kg) | Volumetric Energy Density (Wh/L) |

| Prismatic | 180–250 Wh/kg | 600–750 Wh/L |

| Cylindrical | 200-260 Wh/kg | 500-700 Wh/L |

Cycle Life

- Cylindrical cells excel in longer cycle life compared with prismatic cells. They offer a robust metal casing that can reduce the stress caused by the winding process. Smaller cell design enables cylindrical batteries to evenly distribute thermal loads on the battery pack, reducing battery aging and enhancing battery lifespan.

- Prismatic cells hold large capacity, concentrated heat, and stacked electrode design where the internal temperature gradient is higher, which can accelerate aging. This design tends to reduce the overall cycle life of prismatic cells.

Thermal Management

Promising thermal management is pivotal in safeguarding safety for all types of lithium-ion batteries. Overheating causes capacity decay and voltage fluctuations, triggering thermal runaway.

- A prismatic cell has a larger size, a stack structure, and a large electrode area, and generates more concentrated heat, easily causing thermal runaway. Therefore, it is critical to take an immersive cooling system to control temperature and a BMS to monitor battery status in real time.

- Cylindrical cell outshines in thermal management. It uses a wound electrode sheet structure, and its strong metal shell and small size make it easy to dissipate heat. Heat can be evenly distributed throughout the entire battery pack, reducing local overheating risk. This feature makes battery charging and high-rate discharge safer.

Manufacturing and Cost

Cylindrical cells are a cost-effective choice for standardized dimensions and superior consistency. Mass market production and mature supply chain also contribute to lower costs.

Prismatic cells require customized housings and assembly processes, which are costly. They features with complex manufacturing processes and compact structures, but they have difficulty dissipating heat and require additional design costs.

Battery Testing and Certification

Both Cylindrical and prismatic cell lithium batteries must the rigorous safety and quality standards before entering into international market, such as UN38.3, IEC certifications. That’s because different types of cells show different performance in thermal management, cycle life, and energy density.

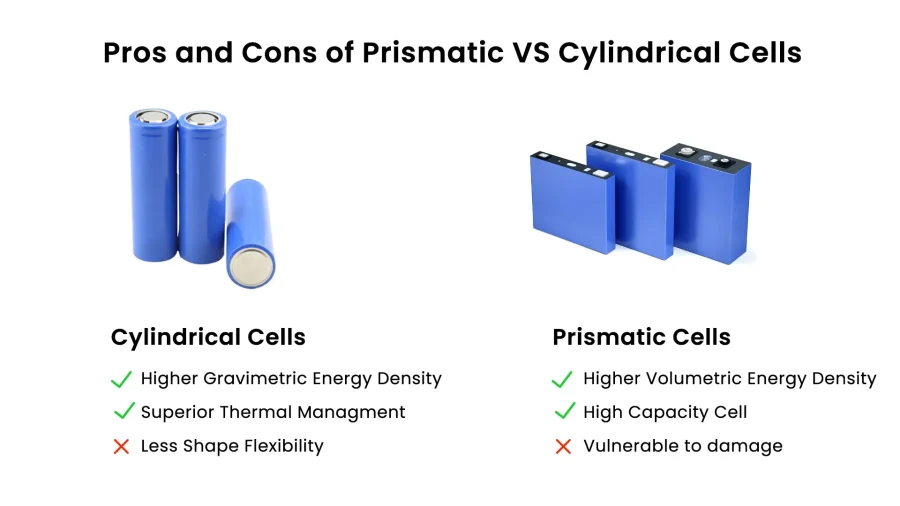

What are the advantages and disadvantages of Prismatic VS Cylindrical Cells?

Advantage of Prismatic Cells

- High space utilization: Prismatic Cell has a regular shape that allows for highly efficient assembly, making it suitable for high-capacity applications, such as robots.

- Superior safety. It boasts a hard shell, providing mechanical strength and robust resistance to crushing.

- Flexible design. Its size can be customized into different shapes, meeting specific needs.

Disadvantages of Prismatic Cells

- Low standardization: Specifications vary significantly between manufacturers, resulting in high costs.

- Heat dissipation challenges: Large prismatic cells lead to internal heat accumulation, requiring complex thermal management.

Advantages of Cylindrical Cells

- High Standardization. Mature automated production ensures low costs and high yields.

- Superior Safety. They include independent protection for each unit, preventing thermal runaway from fire spread.

- Excellent Heat Dissipation: Its cylindrical shape facilitates uniform heat dissipation.

Disadvantages of Cylindrical Cells

- Low grouping efficiency: The Cylindrical battery has a gap, resulting in low volume utilization. Thus, it requires structural filling.

- Limited energy density. Small cell capacity is suitable for low-power applications.

- Sensitive to mechanical stress: Long-term vibration causes weld fatigue.

Prismatic vs. Cylindrical Cells: Application Explained

Applications of Prismatic Battery Cells

Prismatic cells can be stacked without gaps, offering over 20% higher space utilization compared to cylindrical cells. This makes them ideal for high-energy-density applications, such as long-range electric vehicles. Their hard-shell design, often using aluminum alloy casings, provides excellent mechanical strength and crush resistance, ensuring stable performance in energy storage systems and aerospace equipment. However, large individual cells are prone to heat buildup and typically require complex liquid-cooling systems.

- Robot: Ternary lithium battery pack assembled from prismatic cells is a perfect solution. Prismatic cells offer higher volume utilization, powering a battery pack to achieve higher energy density with a lightweight design. NMC chemistry provides enhanced runtime.

- Marine Boats: Low-temperature battery packs assembled with prismatic cells efficiently leverage volume, providing a battery pack with larger capacity and better discharge performance within limited space.

Applications of Cylindrical Battery Cells

Cylindrical cells, standardized in sizes like 18650 and 4680, enable low-cost mass production. Each cell’s independent structure prevents thermal propagation, which is particularly advantageous in consumer electronics, power tools, and humanoid robots. Their round cross-section, combined with spacing between cells, naturally supports immersion cooling, improving heat dissipation efficiency by up to 30%. The downside is that when grouped, cylindrical cells leave 15–20% unused space, necessitating extra filler structures.

- Ebike: Cylindrical battery cells feature with winding structure, reducing overheating risk and maintaining stable operation during high-rate discharge. Various cylindrical cells, such as 18650, 21700, can be combined into battery packs with different capacities and voltages to meet the power needs.

- Medical Devices: Cylindrical cells can be flexibly connected in series and parallel to improve capacity and stable output power to match the strong energy needs of various medical devices, such as portable monitors, infusion pumps.

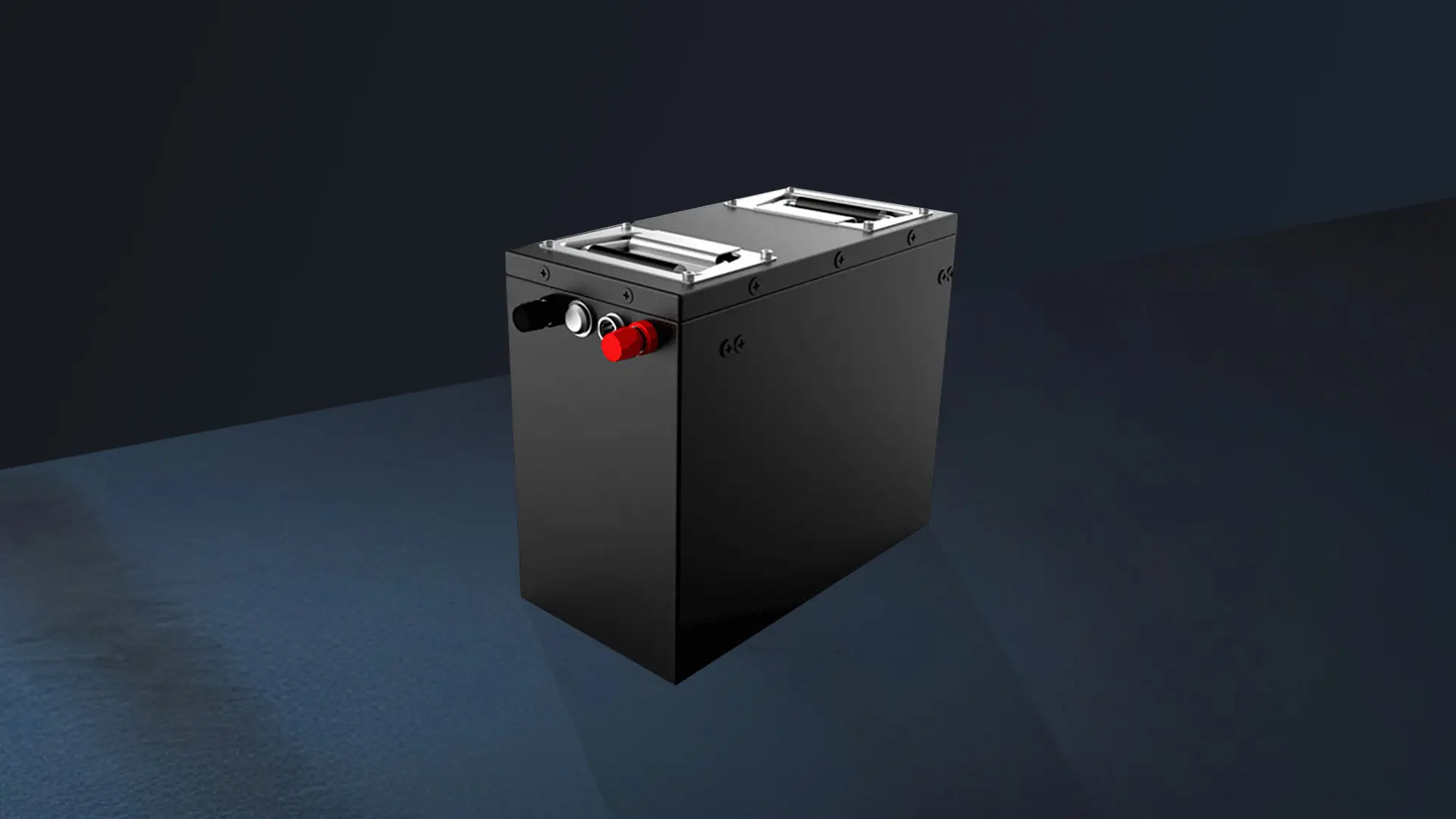

How to Choose between Prismatic VS Cylindrical Cells?

In a nutshell, consider your specific application requirement when choosing between prismatic and cylindrical lithium-ion cells. Prismatic cells offer higher capacity, exceptional energy density with layer structures, powering high-drain devices needing compact space and strong output, such as robotics, marine vessels. Cylindrical cells boast superior thermal management and excellent mechanical durability, supporting power for high-rate discharge devices in harsh conditions, such as electric bikes, medical devices.

CM Batteries is a professional custom lithium-ion battery pack manufacturer. We not only provide different types of battery cells, but also assemble the cells into battery packs based on needs, and provide advanced BMS, battery structure design, and various technical support. If you have any requests, please contact us.