In applications ranging from solar energy storage to electric vehicles and backup power systems, the depth of discharge (DoD) plays a critical role in battery health and lifespan. Deep discharge—using more than 80% of a battery’s capacity—is not inherently harmful, but if left uncontrolled, it can significantly reduce the battery’s cycle life.

This article explores the concept of depth of discharge, its relationship with State of Charge (SoC), how deep discharge impacts battery longevity, and strategies to prevent excessive discharge.

What Does Depth of Discharge Mean?

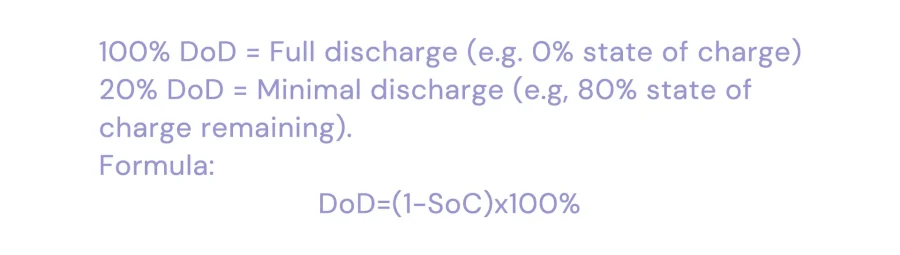

Depth of Discharge (DoD) refers to the percentage of a battery’s capacity used during each discharge cycle, operating inversely to the State of Charge (SoC). Manufacturers set DoD limits to balance energy output and battery longevity, as deep discharging accelerates degradation and reduces cycle life.

Effective DoD management ensures a stable SoC, maintains the State of Health (SoH), and extends battery lifespan. This optimization allows industrial and energy storage systems to achieve peak efficiency while ensuring long-term reliability.

How to Calculate the Battery’s Depth of Discharge?

Depth of Discharge (DoD) measures the percentage of a battery’s total capacity consumed during a discharge cycle. The formula for DoD is:

Step-by-Step Calculation

- Determine Discharged Capacity (Ah)

C=Current (A)×Discharge Time (hours)

Example: If a battery discharges at 10A for 8 hours, its discharged capacity is: C=10A×8h=80Ah

- Identify Nominal Capacity (Ah)

This is the manufacturer-rated total capacity (e.g., 100Ah) under standard conditions.

- Compute DoD (%)

Calculate the depth of discharge based on the battery’s discharge capacity (80Ah) and nominal capacity (100Ah): DoD =(80Ah÷100Ah)×100=80%

Most battery systems enforce DoD limits of 80-90% to optimize the battery’s performance and longevity. Avoiding 100% DoD prevents excessive degradation, preserving cycle life and State of Health (SoH).

How Does Deep Discharge Affect a Battery?

Repeated deep discharging (frequently draining a battery beyond its recommended DoD) accelerates capacity loss, hastens aging, and significantly shortens cycle life, leading to premature device failure.

To optimize battery health and performance, it’s critical to understand how the following factors influence longevity, efficiency, and safety:

- Depth of Discharge (DoD) – Higher DoD (e.g., 80-100%) strains battery chemistry, reducing lifespan.

- Cycle Life – Each deep discharge cycle degrades electrodes faster than partial cycles.

- Temperature – High temperatures exacerbate degradation during deep discharges.

- Charge/Discharge Rates – Rapid discharges at high currents increase internal stress.

- Battery Chemistry – Lithium-ion tolerates deeper cycles better than lead acid, but limits still apply.

Proactive management of these factors ensures the battery’s maximized performance and extended service life.

How Does Depth of Discharge(DoD) Impact Battery Cycle Life?

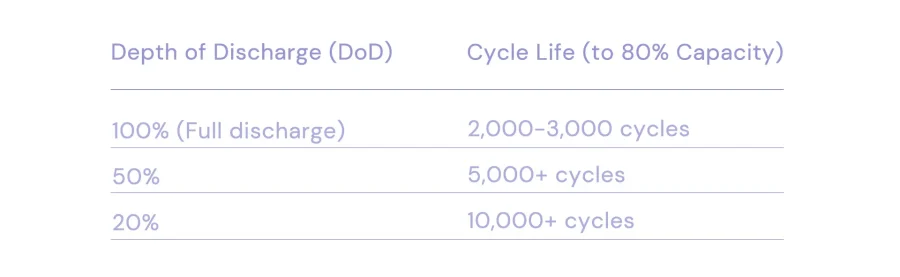

To optimize your battery’s longevity, it’s essential to understand the relationship between the battery’s depth of discharge (DoD) and cycle life.

- DoD represents the percentage of a battery’s capacity used in a single cycle.

- Cycle life refers to the number of full charge-discharge cycles a battery can endure before its capacity degrades to 80% of its original rating.

1. Lower DoD = Longer Lifespan

A battery cycled at 20% DoD may last 3–5x longer than one cycled at 100% DoD.

2. Trade-off: While deeper discharges (high DoD) maximize energy use, they accelerate aging.

3. Pro Tip: For applications like solar storage or EVs, aim for 50–80% DoD to balance performance and longevity.

Depth of Discharge (DoD) and cycle life share a critical inverse relationship: the deeper you discharge a battery, the fewer cycles it will deliver. This is pronounced in LiFePO4 batteries, where strategic DoD management can extend lifespan.

LiFePO4 Cycle Life vs. DoD: Real-World Examples

In a word, by minimizing Depth of Discharge (DoD)— using less of the battery’s capacity per cycle—you dramatically increase its total cycle life while maintaining consistent performance.

Deep Discharge Increases Internal Resistance and Reduces Efficiency

Over-discharging a battery worsens electrode polarization and significantly increases internal resistance. These effects create a vicious cycle: performance impacts, thermal consequences, and long-term damage.

Deep Discharge Increases Safety Risks

Deep discharge of batteries generates heat, increasing thermal runaway risk, fire, and explosion. Deep-discharged batteries may undergo structural damage and separator deformation. In lithium-ion batteries, lithium dendrites may develop on the anode, piercing the separator and causing internal short circuits.

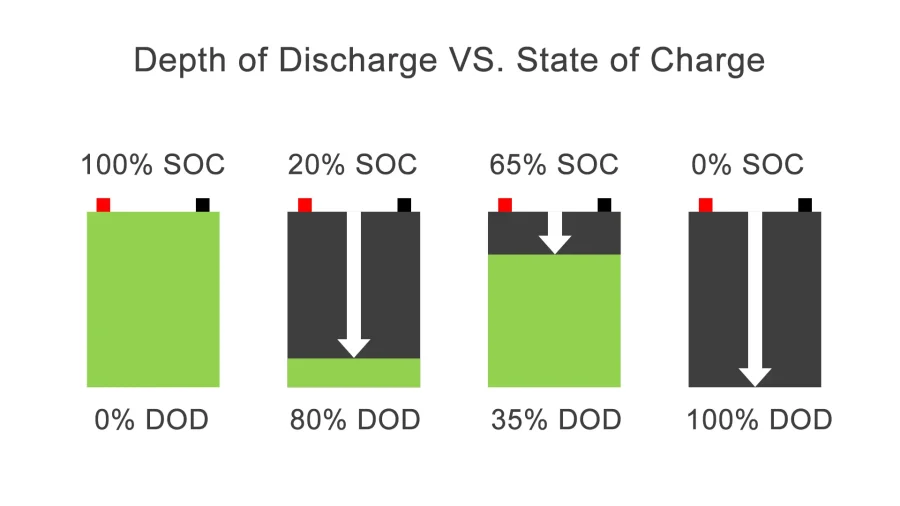

What is the Difference Between Depth of Discharge VS State of Charge?

The depth of discharge (DoD) is a measure of the percentage of a battery’s total capacity that has been discharged, while the state of charge (SoC) is an indication of the percentage of remaining available capacity. DoD and SoC are always complementary and will always add up to 100%.

SoC is defined by the formula:

SoC (%) = 100 − DoD (%)

For instance, an 80% SoC battery has retained 20% DoD.

Understanding the inverse relationship between DoD and SoC enables precise energy management, paving the way for smart battery management.

By limiting the DoD, battery systems can prevent over-discharge failures, such as lithium plating in the case of Li-ion cells. By tracking SoC, they can use recharge optimization to achieve optimum battery lifespan.

Intelligent Battery Management Systems (BMS) utilize the principle to calculate DoD and SoC in real-time, and offer cell balancing on discharge.

Types of Batteries That Can Handle Deep Discharge

LiFePO4 batteries leverage exceptional thermal stability to withstand deep discharges (80-100% DoD) with minimal capacity loss. The LiFePO4 battery pack has a cycle life of more than 3,000 times at full DoD, making it ideal for high-energy-density applications such as solar energy storage systems, electric vehicles, and industrial UPS backup power.

Lead-acid batteries support moderate deep cycling but are limited by several performance constraints. Voltage rebound after discharge can delay accurate state-of-charge readings, complicating charge management. When the state of charge(SOC) drops below 50%, sulfation begins to form on the plates, leading to capacity loss. These batteries are also highly sensitive to low temperatures, with usable capacity dropping by more than 40% at sub-zero conditions.

| Parameter | LiFePO4 batteries | Lead-acid batteries |

| Deep Discharge | Support 100% DoD cycling | Battery’s DoD accelerates plate corrosion |

| Cycle Life (100% DoD) | Over 3,000 cycles; retain 80% capacity | 300 cycles; remain 60-70% capacity |

| Safety | Built with Smart BMS to prevent thermal runaway | No BMS. Overheating causes plate sulfation or damage |

| Temperature Performance | Operates at -40°C to 85°C | Capacity drops 40% below 0°C; Freezing risk during deep discharge |

| Applications | Solar energy storage Marine propulsion Deep-cycle backup systems | Automotive SLI batteries Short-duration UPS |

Therefore, many battery manufacturers tend to choose LiFePO4 batteries to match their application. Compared with lead-acid batteries, LiFePO4 is more stable, has a wider temperature range and intelligent BMS, and maintains a higher battery cycle life at a high depth of discharge.

How to Prevent Deep Discharge of the Battery?

To minimize deep discharge risks, adopt these simple suggestions:

1. Monitor Depth of Discharge and Charging Cycles

Limit discharge depth to 20%–30% for maximum battery life. Avoid fully discharging when being used. Regular recharging prevents extended low-voltage conditions, maintaining electrochemical stability.

2. Optimize Charging Protocols

Recharge the battery from 20%–30% remaining capacity. Employ certified fast chargers and ensure ambient temperatures lower than 45°C during charging in order to reduce thermal stress.

The Role of Battery Management Systems (BMS)

A BMS continuously monitors voltage, current, and temperature and calculates State of Charge (SOC) and State of Health (SOH). When the voltage is less than the discharge cut-off voltage, it cuts off the load circuit to prevent over-discharge.

Balancing Methods Enhance Protection:

- Passive Balancing: Diverts surplus energy through resistors as heat to equalize cell voltages.

- Active Balancing: Using a capacitor or inductor circuits for transferring energy from cell to cell, maintaining pack equilibrium in discharge cycles.

How Shallow Charging Extends Ternary (NMC) Battery Life?

Ternary lithium batteries, Nickel Manganese Cobalt (NMC), possess a high energy density of approximately 200–300 Wh/kg. Their layered oxide cathode, however, is more reactive than the one in LiFePO4 batteries and hence more susceptible to deep discharge, leading to higher capacity loss and shorter lifespan.

The Effect of Deep Discharge (100% DoD):

NMC batteries will achieve 1,000–1,500 full cycles before achieving an 80% capacity loss due to processes such as cathode fatigue, lithium deposition, electrolyte oxidation, and SEI layer growth. These processes are heightened when the battery is cycled deeply to its voltage or capacity limit.

The Advantages of Shallow Cycling:

Operating within a 20%-80% SoC range significantly reduces battery degradation mechanisms. This strategy optimizes cycle life, in some cases, more than 2,000 cycles and 80% capacity retention. At the same time, shallow charge and discharge can provide longer stability in SoH and excellent thermal management.

Comparison table of deep VS shallow discharge in NMC batteries

| Characteristic | Deep Discharge (DoD ≈ 100%) of NMC batteries | Shallow Discharge (DoD ≈ 20%–80%) of NMC batteries |

| Energy per Cycle | High (close to rated capacity) | Moderate (lower usable energy per cycle) |

| Cycle life | 500–800 cycles | 1500–2500 cycles or more |

| Energy Density Performance | High initially, but degrades faster | More stable over time |

| Capacity Retention (SoH) | Rapid decline, early capacity loss | Slower degradation, longer SoH stability |

| Heat Generation | Higher, more stress on thermal systems | Lower, easier thermal management |

| Safety | Lower; higher risk of over-discharge or overheating | Higher, avoids voltage extremes |

Conclusion:

Excessive battery deep discharge, or draining a battery below 80% capacity, drastically shortens cycle life, increases internal resistance, and elevates safety risks like thermal runaway. Efficient methods include operating in 20%-80% state-of-charge(SOC) ranges and employing battery management systems.

Dive Deeper: Explore how cycle life compares to shelf life and calendar life in our guide: Complete Guide to Lithium Battery Shelf Life, Cycle Life, and Calendar Life.

One thought