Lithium-ion batteries are the major rechargeable battery technology due to their high energy density, extended cycle life, and minimal self-discharge, and they energize everything from smartphones and laptops to electric vehicles and grid-scale energy storage systems. However, limited lithium reserves and costly extraction have generated a need for alternatives. Sodium-ion batteries are promising, founded on the abundance and cheapness of sodium. Then, I will introduce the component, working principle, cost, energy density, cycle life, safety, performance, and application of both batteries.

Sodium-ion Batteries VS. Lithium-ion Batteries Comparison

Sodium and lithium possess varying physical properties even though they are alkali metals of the same group. These intrinsic differences directly influence their electrochemical behavior when engineers utilize both in battery applications. Being two distinct rechargeable battery technologies, both sodium-ion and lithium-ion batteries possess varying advantages and drawbacks in various aspects.

Sodium VS. Lithium Battery Chemical Components

- Sodium-ion Batteries (SIBs)

Cathode materials: Transition metal oxides’ sodium compounds (e.g., NaFeO₂), phosphates (NaFePO4), sulfates (Na₂Fe₂(SO₄)₃), and Prussian blue analogs (Na₂Fe[Fe(CN)₆]).

Anode materials: Specially designed carbon materials – hard and soft carbons with stable sodium ion storage

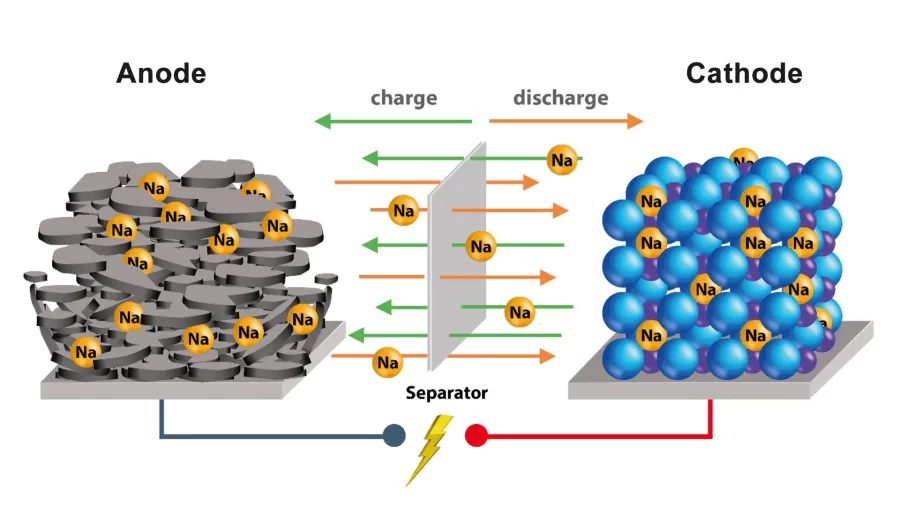

Working principle: On charging, the sodium ions move from the cathode to the anode and get deposited in the carbon structure. On discharging, the sodium ions move towards the cathode, releasing energy to charge devices.

- Lithium-ion Batteries (LIBs)

Cathode materials: Lithium-containing materials such as lithium cobalt oxide (LiCoO₂), lithium iron phosphate (LiFePO₄), and lithium nickel manganese cobalt oxide (NMC).

Anode materials: Graphite is the most common choice, though some newer models use silicon or lithium titanate (LTO) for improved performance.

Working principle: When charging, lithium ions migrate from the cathode to the anode, where they are sandwiched between graphite layers. When discharging, the lithium ions travel back toward the cathode, generating an electric current.

Sodium-ion Battery VS. Lithium-ion Battery Cost

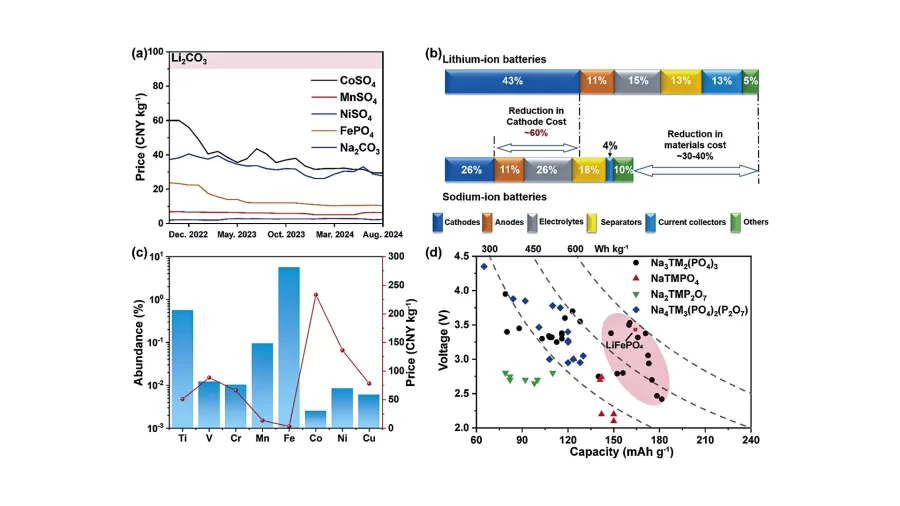

Theoretically, sodium-ion batteries have the merit of low material costs. Sodium makes up 2.3% of Earth’s crust – 400 times more abundant than lithium (just 0.0065%) – and spreads more evenly worldwide. Sodium batteries use cheap aluminum foil for both electrodes, potentially slashing material costs by 30-40% versus lithium-ion batteries.

But the reality is not optimistic: manufacturers have not started mass-producing sodium batteries, while lithium iron phosphate (LFP) battery prices keep plunging and hit rock bottom in 2025. These conditions have nearly erased the cost difference.

Sodium Battery VS. Lithium Battery Energy Density

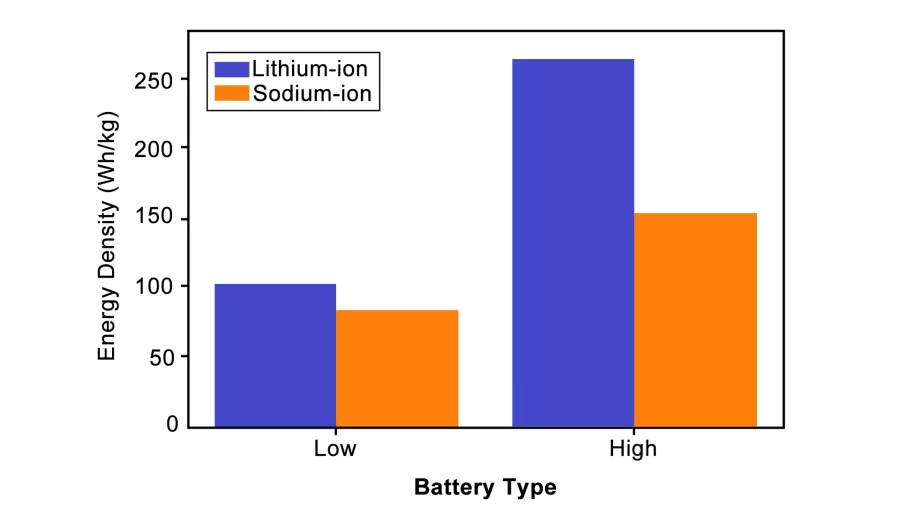

Sodium ions are larger than lithium ions, so sodium-ion batteries also have lower voltages and lower gravimetric and volumetric energy densities. Sodium-ion batteries typically offer 100-150Wh/kg with an operating voltage of 2.8- 3.5V, which puts them on the same footing as some lithium iron phosphate (LFP) batteries in certain applications.

While LFP batteries are still under 200Wh/kg, more lithium nickel manganese cobalt (NMC) and similar chemistries reach 200-300Wh/kg, making them the go-to choice for space-constrained uses like smartphones and EVs where every gram counts.

However, sodium-ion still falls behind its high-performance lithium-ion counterparts. Therefore, the technologies are complementary to each other. Lithium-ion dominates in energy-intensive applications, and sodium-ion emerges as a cost-effective option for stationary storage and less weight-sensitive applications.

Sodium-ion VS. Lithium-ion Batteries Cycle Life

Due to the constraints in manufacturing processes and materials, current commercial sodium-ion batteries typically can only provide 3,000-4,000 cycles.

Lithium-ion Batteries, such as Lithium iron phosphate batteries, are ahead in this aspect, with commercial 314Ah energy storage cells now offering over 12,000 cycles. This performance gap reflects the difference in maturity between sodium-ion technology and lithium-ion technology in the market.

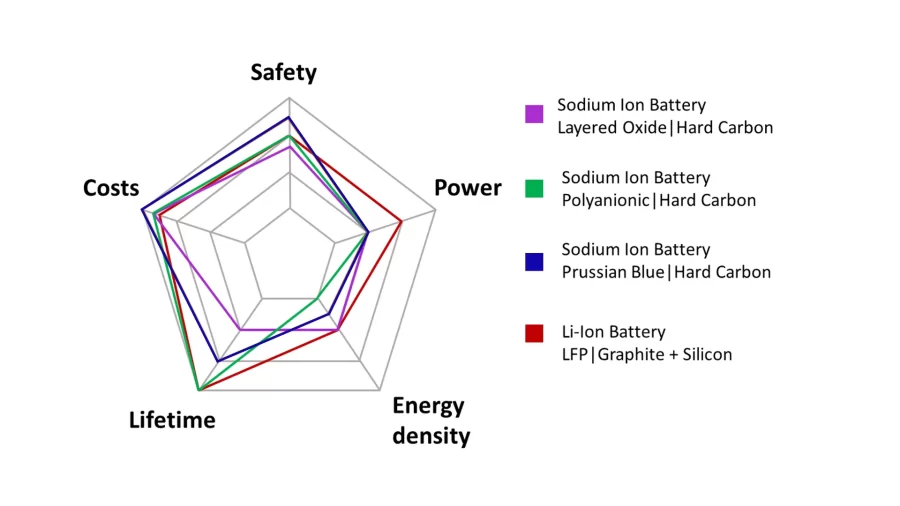

Sodium-ion VS. Lithium-ion Batteries Safety

Sodium-ion batteries show clear safety advantages in operational stability. Independent testing shows they maintain integrity under nail penetration tests without thermal events, with stable performance under short-circuit, overcharge, and compression scenarios. They attribute higher safety margins to their higher thermal activation threshold and slower heat generation rates.

Lithium-ion batteries are prone to a high level of side reactions under various abuse conditions, which lead to thermal runaway. Traditional lithium-ion battery safety accidents are controlled by three types of abuse conditions: mechanical abuse (extrusion, puncture), electrical abuse (short circuit, overcharge, over-discharge), and thermal abuse (overheating).

Here I’ve also done a table breakdown based on the main differences between Sodium-ion batteries VS lithium-ion batteries:

Sodium ion batteries VS lithium ion batteries

| Feature | Sodium ion batteries | Lithium-ion batteries |

| raw materials | Abundant (2.3% of Earth’s crust) | Rare (0.0065% of Earth’s crust) |

| Size | Bulky | Light |

| Energy density | 100-150wh/kg | 140-280wh/kg |

| Cycle life | 3,000-4,000 cycles | over 12,000 cycles |

| Charging Speed | charge 80% in 12 minutes | charge over 80% in 45 minutes |

| –30°C Capacity Retention Rate | Maintains 92% performance | Maintain 80% performance |

| Thermal Runaway | 350°C(662°F) | 270°C(518°F) |

| Application | Energy storage, Low-speed Electric Vehicles, low-temp e-bikes | IoT devices, Power tools, Medical devices, Robot, eFoil |

| Environmental Impact | Minimal environmental impact, lower carbon emissions. | Serve pollution, resource scarcity, high carbon emissions. |

Sodium VS Lithium Battery Performance

While conventional lithium batteries perform poorly in the cold, sodium-ion battery technology maintains 92% discharge capacity at -30°C, putting an end to lithium’s cold-weather performance woes. CATL’s sodium-ion cells also reach 80% charge in just 15 minutes at room temperature, with stable operation from -40°C to 80°C. However, their greater weight and lower energy density limit their applications to low-speed vehicles for the time being.

Standard lithium batteries perform optimally in the range of 20-30°C, with performance declining outside this range. What’s CMB’s innovative solution? Custom lithium battery packs featuring wide-temperature operation (-20°C to 85°C) with waterproof and heat-resistant BMS technology. This innovation bridges the gap between sodium-ion’s temperature resilience and lithium’s energy density, delivering reliable power where standard batteries fail.

The landscape shifted dramatically in July 2021, when CATL unveiled its sodium-ion battery, targeting full-scale production by 2023. Soaring lithium prices in 2022 further accelerated industry adoption. On April 21, 2025, CATL achieved another milestone by launching the world’s first mass-produced sodium battery—the CATL Sodium New—transitioning the technology from niche applications to broad commercialization and reshaping global energy infrastructure.

Sodium VS Lithium Batteries Applications

Are sodium batteries better than lithium batteries? The answer is no. Lithium-ion batteries still dominate, with Ningde Times leading the way with a 35% market share, and BYD and LG Energy Solutions combining for 21%. However, we cannot ignore geopolitical factors: China dominates the lithium-ion industry chain, while the United States, a major supplier of sodium carbonate, is pushing for energy independence to reduce its dependence on China.

Although sodium-ion batteries have a bright future in energy storage (market share is expected to reach 30% in 2030), their commercialization still faces core challenges – sodium atomic mass is three times that of lithium, resulting in 30% lower energy density, and the redox potential is also 10%-25% weaker, which seriously affects the range of electric vehicles. Despite attempts by JAC and other companies to try sodium-electric models, lithium iron phosphate (LFP) batteries are accelerating to capture the market by similar costs (almost equal to sodium) and longer cycle life. Industry forecasts show that by 2030, NMC and LFP batteries will occupy 42% and 41% share, respectively. Sodium-ion batteries will need to overcome performance limitations to compete for a slice of the pie.

The 2025 current lithium pricing is at a low level, reducing the cost advantage of sodium-ion batteries. Industry sources noted that low energy density makes sodium batteries mostly fit for two-wheeled vehicles and small cars. Although sodium battery technology will advance, experts feel that the range will never be able to exceed high-end lithium batteries, which should be positioned to fill particular market segments (like short-distance micro-electric cars).

Compared with sodium-ion batteries, lithium-ion batteries offer higher energy density, longer battery cycle life, and lighter weight. As a result, lithium-ion batteries continue to dominate today’s battery market, with applications ranging from smartphones to electric vehicles. As a lithium battery manufacturer with 15 years of experience and an R&D engineering team, CMB offers the most customized lithium-ion battery pack solutions to meet any of your needs. For example, customized Lithium Iron Phosphate (LFP) batteries, which cost nearly the same as sodium, are ideally suited to power a wide range of industrial and commercial equipment, including Marine, Golf Carts, and RVs, due to their long cycle life, intelligent BMS, and compact size.

FAQs About Sodium VS. Lithium Battery

1. Why are sodium-ion batteries often compared to lithium-iron phosphate batteries?

Because sodium-ion batteries have a lower energy density than the nickel-based chemistries commonly found in lithium-ion batteries. As a result, sodium-ion batteries suit applications with lower energy requirements better. Would you like to make any other adjustments to this sentence? This makes them ideal for stationary energy storage systems and smaller vehicles where range is not essential. Notably, China’s BYD plans to use sodium-ion batteries in its “microcars,” a clear indication of the market segment it is targeting.

2. Are sodium-ion batteries indeed less costly than lithium-ion batteries?

Sodium-ion technology has been in the spotlight since the price of lithium-ion batteries skyrocketed, driven by supply chain disruptions during the COVID-19 epidemic and geopolitical tensions affecting nickel supply.

However, the situation has changed, and over time, data suggests that the price of lithium-ion batteries could fall below $100 per kilowatt hour (kWh) by 2027. Lithium iron phosphate batteries will become cheaper and cheaper.

3. Can sodium-ion batteries replace lead-acid batteries in terms of peak starting power?

Generally speaking, it can always be replaced. Even an average 2Ah Li-ion battery drill will provide better starting for a 3kW diesel starter.

4. Do you recommend sodium-ion battery packs more?

Depends on the specific application. But with today’s almost equal costs, I recommend lithium-ion battery pack with higher energy density, longer cycle life, while sodium-ion battery pack for low cost, higher safety in low temperature climates. CMB is committed to delivering custom lithium battery pack solution to fit your different needs, so welcome to contact us to get professional solution.

One thought