Our world is progressing quicker than ever before, due to rapidly advancing technologies like lithium-ion batteries, electric vehicles, energy storage systems, and smart devices. Well, unfortunately, the incidents, like the thermal runaway, in battery systems do show that the industry has to focus on the design of effective Thermal Management Systems (TMS) right now. In this new era, Thermal Fluid Simulation is already showing itself to be a game-changer, allowing engineers to finally disrupt traditional design methods and create safer, more efficient battery packs.

What Is Thermal Fluid Analysis?

Thermal fluid analysis uses advanced computer modeling to simulate heat transfer and fluid flow within a battery pack during operation. This technology allows engineers to study the temperature distribution, heat dissipation, and other thermal parameters in a virtual environment, leading to more efficient and precise designs.

Unlike traditional physical testing, thermal fluid analysis accelerates development timelines, reduces the need for physical prototypes, and cuts costs associated with both design and manufacturing.

For an in-depth understanding of battery thermal management systems, check out our guide to Lithium Battery Thermal Runaway.

Key Benefits of Thermal Fluid Analysis

- Faster Design Optimization

During the early design phase, thermal fluid analysis enables engineers to identify and address thermal performance issues. This facilitates rapid iterations to optimize cooling, heating, and insulation solutions.

- Enhanced Safety

By simulating thermal conditions, engineers can identify potential thermal runaway risks and design protective measures to ensure reliable operation, even under extreme conditions.

- Lower Development Costs

Simulation technology offers significant cost and time savings compared to the expensive and resource-intensive process of creating and testing multiple physical prototypes, making it ideal for custom battery pack designs.

- Versatile Applications

Thermal fluid analysis can be applied to a wide range of use cases, tailored to specific performance requirements such as high-rate discharge, low-temperature startup, and more.

For more information on our cost-effective custom battery solutions, check out our overview of custom battery pack options.

Case Study: Optimizing Thermal Management for eFoil Batteries

Effective thermal management is crucial to ensuring both the safety and performance of power batteries in real-world applications. This case study demonstrates how thermal fluid analysis was used to enhance the thermal management of eFoil surfboard power batteries.

Initial Simulation and Problem Identification

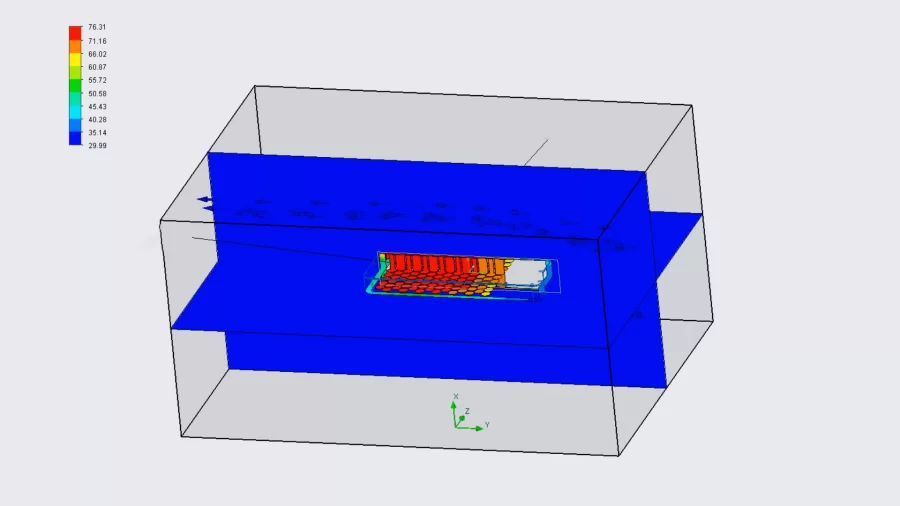

Engineers employed thermal fluid analysis to assess the heat distribution within the eFoil power batteries. The initial simulation revealed several key issues.

- The battery’s maximum temperature reached 76.3°C, exceeding its safe operating range.

- A temperature variation of around 10°C between cells caused uneven heat distribution, which could potentially lead to performance degradation or thermal runaway.

Optimized Design and Results

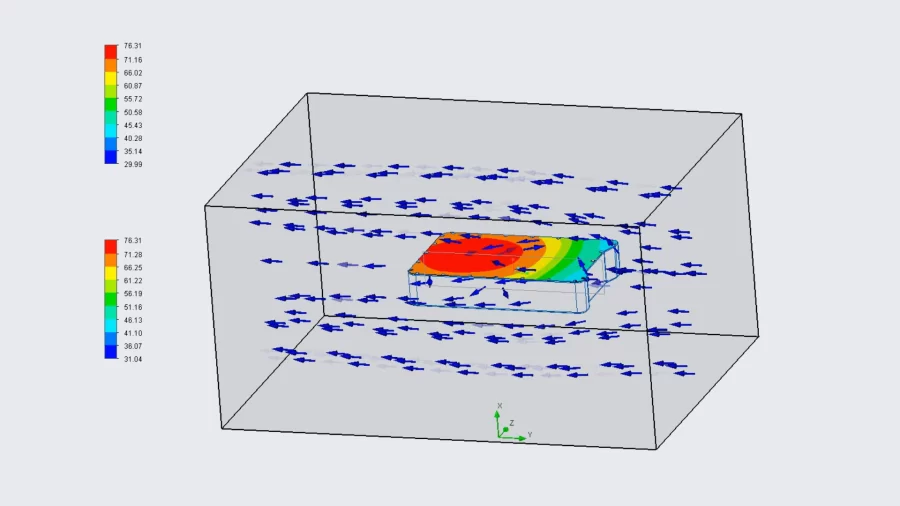

Optimized the fins on the heat-dissipating aluminum plate for better heat transfer.

Enhanced the thermal conductivity of the heat-conducting material by selecting a higher-performance material.

The final simulation results demonstrated significant improvements:

The maximum battery temperature was reduced to 56°C, greatly enhancing thermal safety.

Cell temperature variation was reduced to 6°C, ensuring more consistent heat distribution across the pack.

This process not only reduced testing costs but also provided reliable data for mass production, highlighting the practical benefits of thermal fluid analysis.

Thermal Fluid Analysis in a Battery Pack Design Process

Thermal fluid analysis typically involves four key steps:

- Creating a Simulation Model

Develop a 3D model of the battery pack, incorporating modules, cooling systems, and the surrounding environment.

- Defining Boundary Conditions

Set operational parameters, including heat source locations, cooling methods, and ambient temperatures.

- Simulation Analysis

Use specialized software to simulate heat transfer and fluid circulation based on different production conditions. This analysis provides detailed data on thermal behavior and flow fields.

- Design Optimization

Iterate on the design based on simulation results, modify the model as needed, and re-value each iteration until the optimal solution is achieved.

Benefits for Battery Pack Manufacturers

Thermal fluid analysis offers significant advantages for custom battery pack designs, including:

- Faster Product Development

Shorter R&D cycles allow for quicker delivery of tailored battery pack solutions, helping manufacturers meet customer needs more efficiently.

- Safer, More Reliable Products

Optimized thermal management designs reduce the risk of thermal runaway, improving safety and reliability.

- Cost Savings

Simulation reduces the number of design iterations, optimizes material usage, and minimizes development costs. It also helps prevent costly defects that may arise post-design.

- Customizable Solutions for Diverse Requirements

Whether it’s low-temperature startups, high-temperature environments, or specialized applications like waterproofing and explosion resistance, thermal fluid analysis enables fully customized solutions to meet specific needs.

Challenges and Future Outlook

While thermal fluid analysis offers numerous benefits, it also presents certain challenges:

High Precision Requirements: Accurate results depend on large volumes of experimental data, which can be time-consuming and resource-intensive.

Cost of Software and Hardware: The expenses associated with the necessary simulation software and hardware can be prohibitive, especially for smaller operations.

However, advances in simulation technology, coupled with cloud computing and artificial intelligence, are gradually addressing these challenges. These innovations have the potential to revolutionize battery design and are expected to become increasingly prevalent in the renewable energy sector in the coming years

Conclusion: Technology in Service of Customer Needs

At CM Batteries, we understand that our customers demand high-performance, reliable battery solutions. Leveraging advanced thermal fluid analysis technology, we efficiently address unique requirements, delivering economical and high-quality custom battery packs tailored to their needs.

If you have questions about thermal fluid analysis or custom battery pack design, don’t hesitate to contact us. We’re here to explore possibilities with you and provide professional support to bring your project to life.

2 thoughts